Air cushion cylinder having a sealer of air sealing and locking device and the method for preparing the same

A technology of sealing body and buffer body, applied in envelope/bag manufacturing machinery, packaging, transportation and packaging, etc., can solve problems such as damage, low practicability of air buffer body, and inability of air to enter automatically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

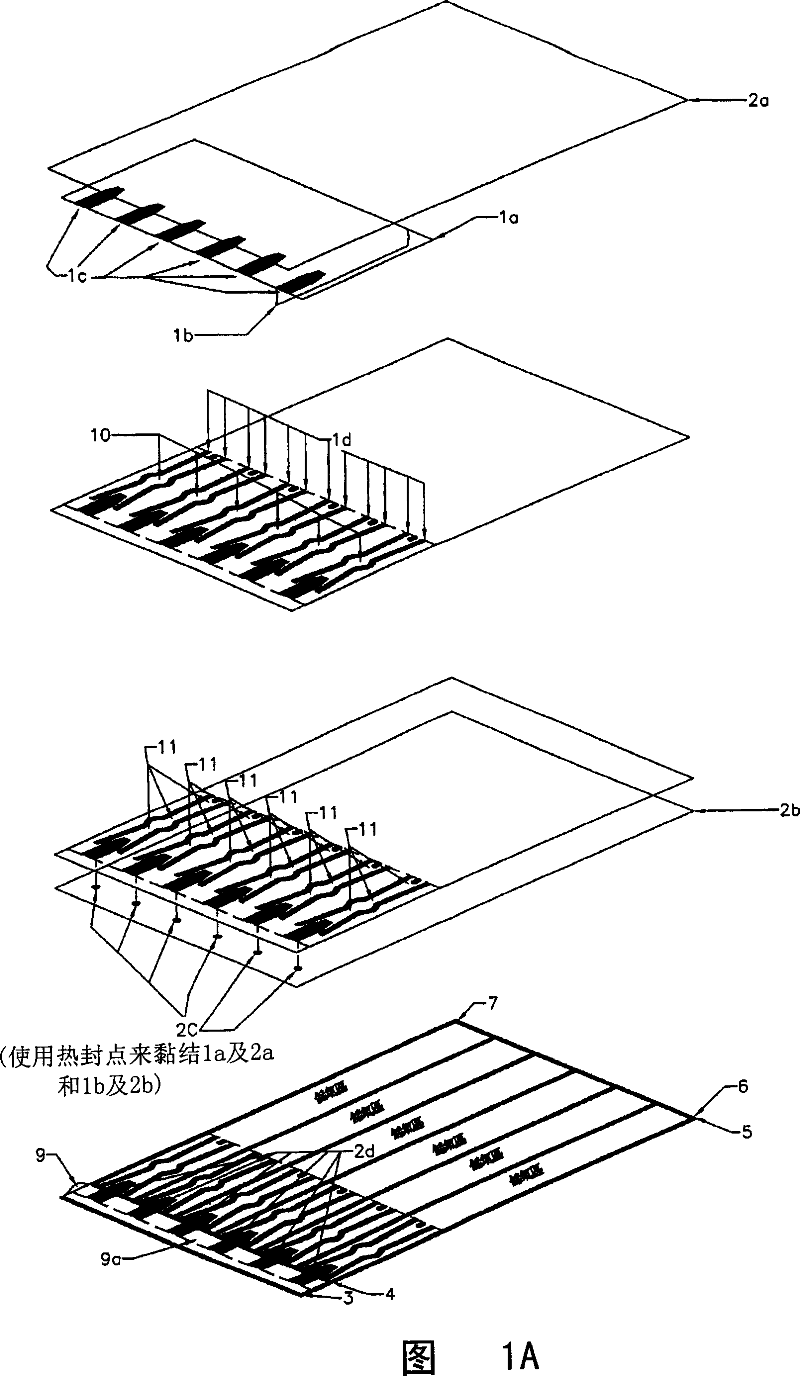

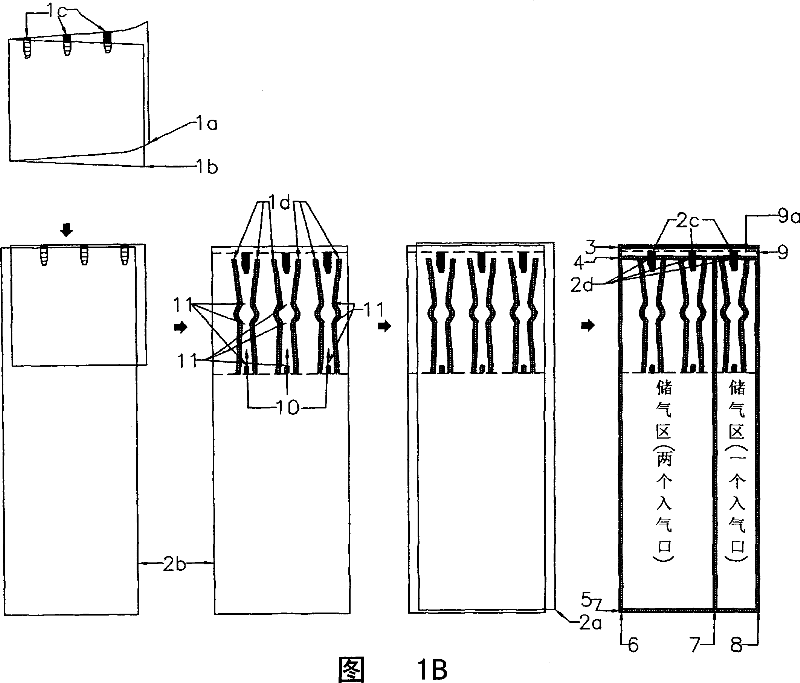

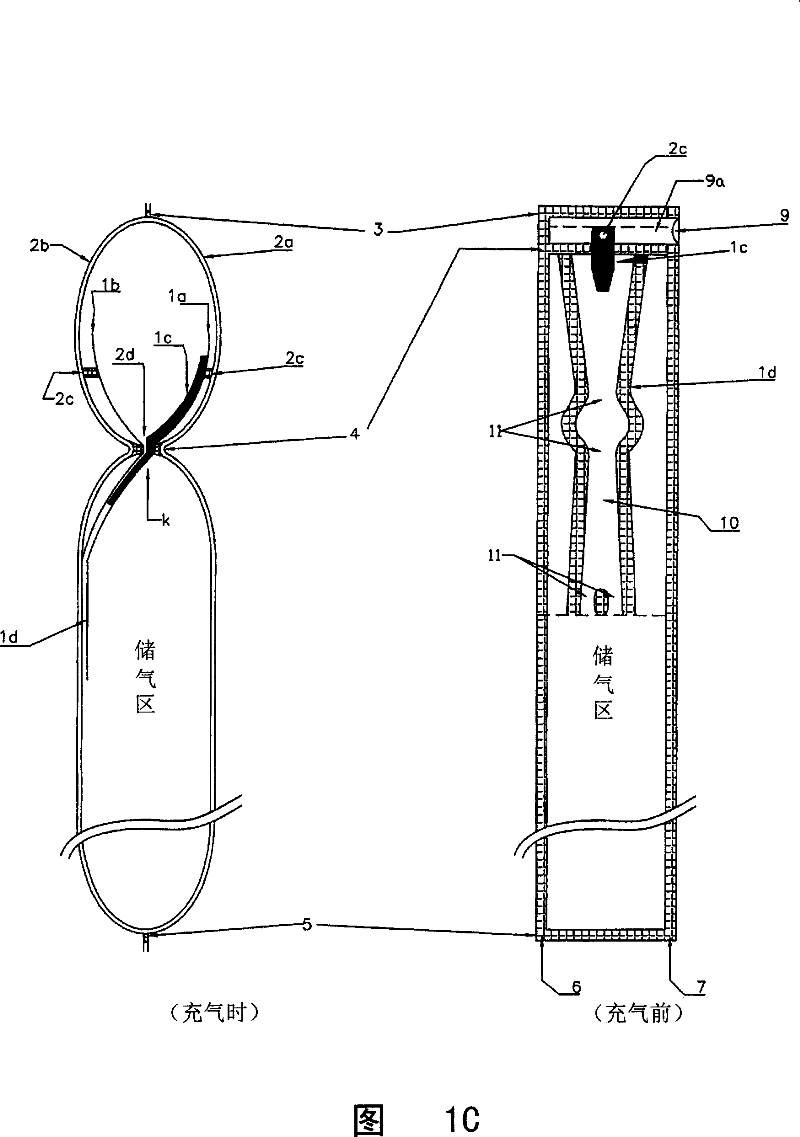

[0015] Please refer to FIG. 1A to FIG. 1C , which show the first embodiment of the air buffer body of the present invention, and the inner membrane adheres to the wall.

Embodiment approach

[0016] The air-filled buffer body includes: two inner membranes 1a and 1b interposed between two outer membranes 2a and 2b. The heat-resistant material 1c is formed between the two inner films 1a and 1b. The implementation is as follows:

[0017] First fold the inner membrane 1a, 1b and the outer membrane 2b, and apply heat seal 1d along the bottom of the heat-resistant joint 1c to form the air path 10, and set the bottleneck that is easy to plug, that is, the easy-to-plug section 11; and then combine with the outer membrane 2a Folding, applying heat-sealing lines 3, 4., 5, 6, 7, 8 to divide the sealing body into two areas, one is the inflatable channel area 3-4, and the other is the gas storage area 4-5, 6, 7 , 8 are heat-sealing edges, make these two districts be bounded by heat-sealing line 4, butt up and down. Due to the heat-resistant properties of the heat-resistant glue 1c in the air-filled channel area, the inner films 1a and 1b are not bonded after being heat-sealed...

no. 2 example

[0039] The second embodiment of the manufacturing method of the air buffer body with the sealing body automatic air-tightening and air-locking device of the present invention, the inner membrane includes the following steps:

[0040] Step 1: Provision of the second inner membrane.

[0041] Step 2: Apply heat-resistant glue on the top of the inner film 1a facing 1b at equal distances, and then heat-seal the air travel path and the preset easy-to-plug section of the two inner films.

[0042] Step 3: The two inner membranes are placed in the middle of the two outer membranes without attaching either side of the outer membranes.

[0043] Step 4: Apply heat-sealing point 2c to the apex of several heat-resistant joints 1c on the outer film.

[0044] Step 5: Apply a heat-sealed horizontal line 4. At the isosceles of the heat-resistant joint of the outer membrane, distinguish the air channel and the gas storage area. Give heat-sealing horizontal line 3,5 again.

[0045] Step 6: App...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com