Electric ballasting rust remover on the inner wall of pipeline

A rust removal machine and pipeline technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of pollution of the conveying medium, cumbersome handling and operation, low rust removal efficiency, etc. , The effect of fast embroidery removal and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

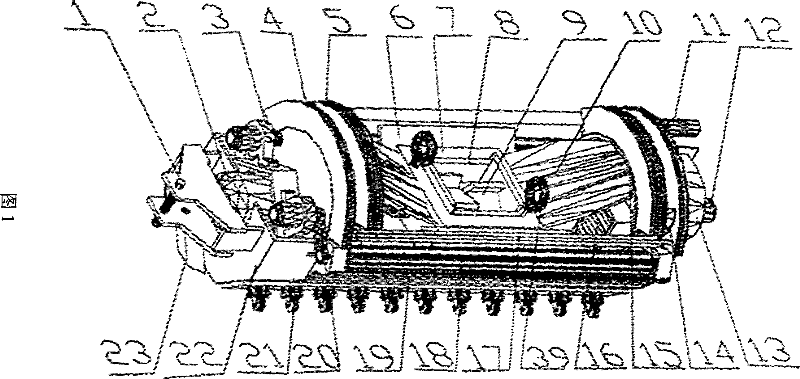

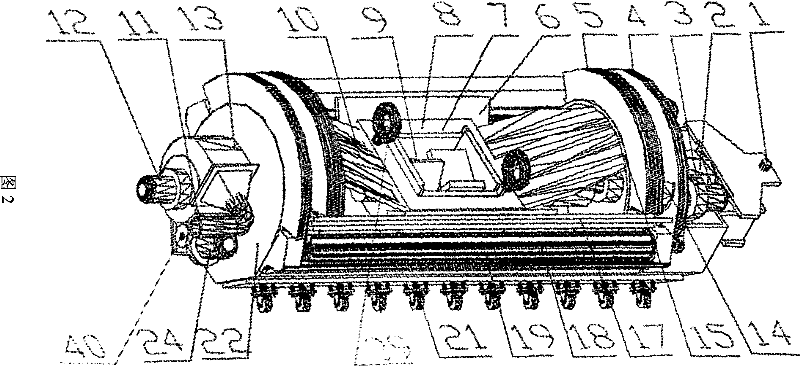

[0022] As shown in FIG. 1 and FIG. 2 , they are a front perspective view and a rear perspective view of the overall structure principle of the embodiment of the present invention, respectively. Among them, the walking system of the electric shot blasting machine for the inner wall of the pipeline in this embodiment mainly includes a traction rod 1, a trolley universal wheel 21, and a trolley frame 22; the sealing system mainly includes an outer layer of steel wire sealing ring brush 4, an inner layer of steel wire Sealing ring brush 5, sand-returning small steel sheet 14, trolley sealing rubber plate 17, shot blasting outdoor guard plate 19; shot blasting system mainly includes shot blasting power motor 2, shot blasting box fixed steel plate 6, shot blasting box 7 , shot blasting box body guard 8, throwing head 9; the sand return system mainly includes the power motor 3 of the return sand roller, the blasting head return sand steel plate 10, the rotary seal return sand roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com