Double-safety regulating valve

A double safety and safety valve technology, applied in the direction of adjusting fuel supply, valve lift, valve details, etc., can solve the problems of high cost and large coil volume, and achieve the effect of simplifying the structure and reducing the total volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

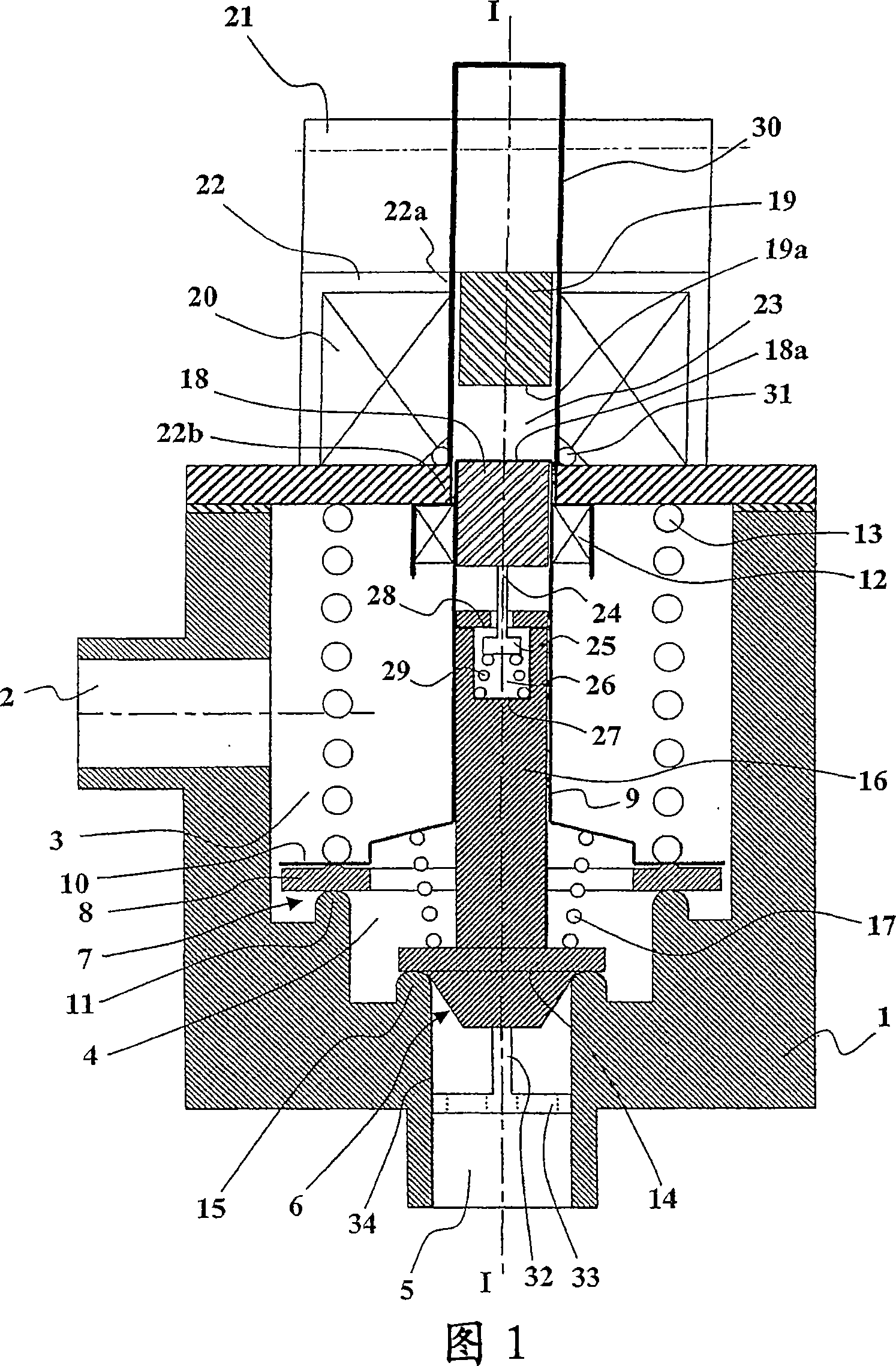

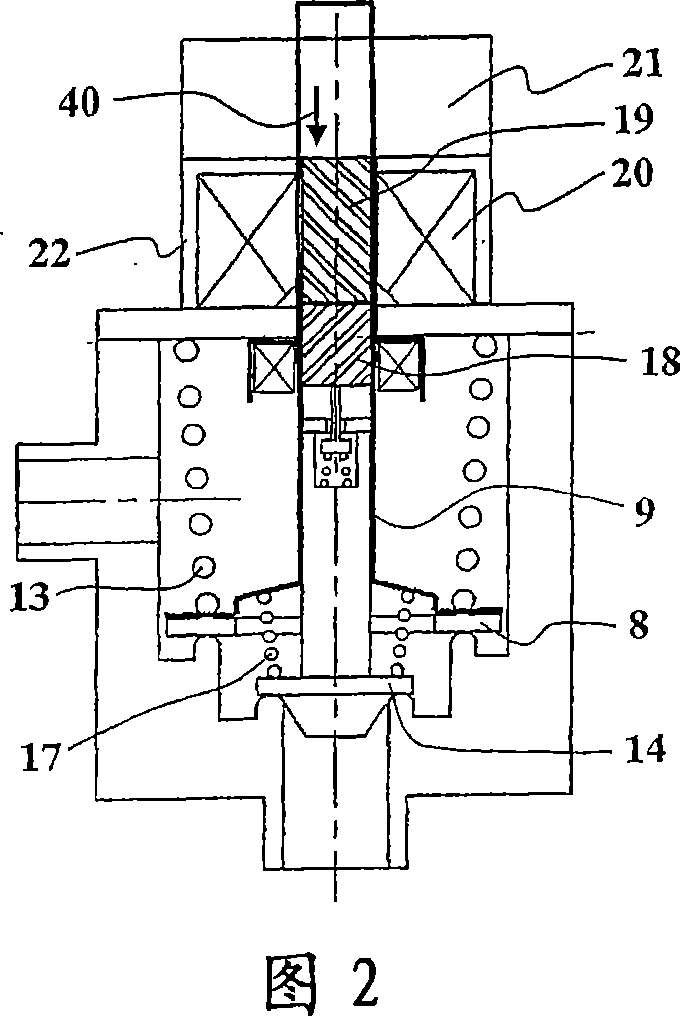

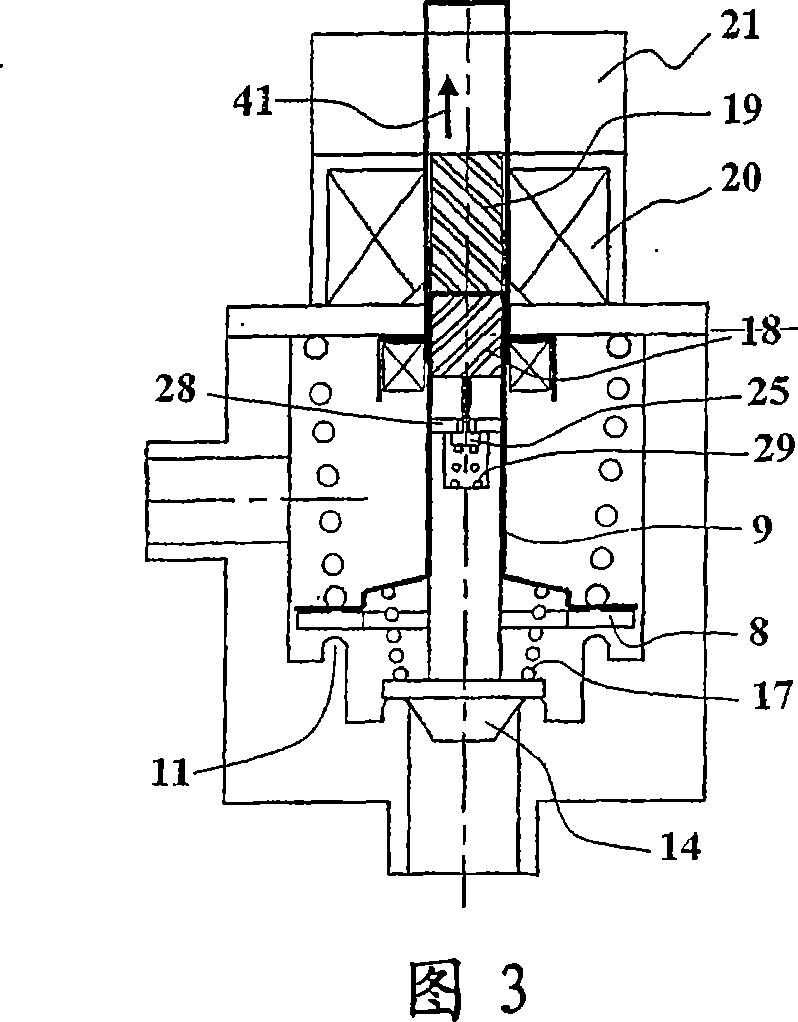

[0048]The dual safety fluid regulating device shown in FIG. 1 comprises a device body 1 in which a fluid passage having an inlet 2 , an upstream chamber 3 , an intermediate chamber 4 and an outlet 5 is provided.

[0049] The device body 1 is also provided with a regulating valve assembly 6 and a safety valve assembly 7, which are connected in series in the fluid passage and arranged one behind the other on a common axis I-I.

[0050] The safety valve assembly 7 comprises a safety valve 8 carried by a hollow axial drive shaft in the form of an axial blind pipe 9 . The open end of the axial blind pipe 9 is fastened on the safety valve 8 . For example, the open end of the axial dead-leg 9 comprises an annular radial lip 10 below which the safety valve 8 is compressed in a sealing manner facing the safety seat 11 and held by eg crimping (crimping). In particular, the edge of the annular radial lip 10 can be bent inwards and engages in an outer radial annular slot on the safety va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com