Device for filtering oil smoke

A technology of oil fume filtration and filter plate, which is applied in the direction of oil fume removal, household heating, heating methods, etc., which can solve the problems of high cost of use, reduction of comprehensive performance of oil fume, and large air volume loss of oil fume filter devices, so as to ensure long-term normal use , Improve the performance of range fume and prolong the maintenance-free time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

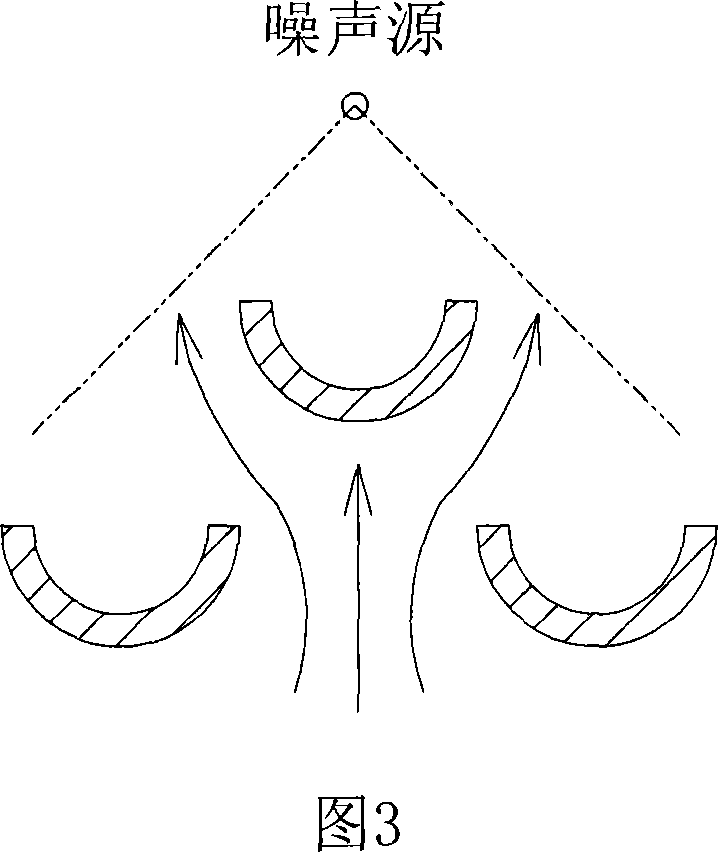

[0048] As shown in Fig. 3 to Fig. 7, it is a preferred embodiment of the present invention. As shown in Figures 3 to 7, the oil fume filtering device of this embodiment is in the shape of a rectangular funnel as a whole, and each side is a double-layer structure composed of two layers of planar filter plates 1, and thus makes the filter plate 1 relatively horizontal. The inclined arrangement means that the plate walls 3 between adjacent ventilation holes 2 on the filter plate 1 are arranged inclined.

[0049] The filter plate 1 is provided with strip-shaped ventilation holes 2 , and the width and spacing of the ventilation holes 2 on the two filter plates 1 are equal, and the ventilation holes 2 on the two filter plates 1 are arranged in dislocation. Flanges 31 are formed around the ventilation holes 1, and the directions of the flanges 31 of the ventilation holes 2 on all the filter plates 1 are all facing the inside of the range hood.

[0050] The cross-sectional shape of t...

Embodiment 2

[0056] As shown in FIG. 8 , with reference to FIGS. 4 to 6 , it is another preferred embodiment of the present invention. As shown in Figure 8, the oil fume filter device of this embodiment is basically the same as the oil fume filter device in Embodiment 1, the only difference is that the shape and relative size of the plate wall 3 between the adjacent ventilation holes 2 on the filter plate 1 are different. Specifically: in the present embodiment, the cross section of the plate wall 3 between the adjacent ventilation holes 2 on the filter plate 1 is a straight line segment and arc-shaped flanging 31 is extended at the two ends of the straight line segment. The width of the ventilation hole 2 is 10mm, and the ventilation The height H of the flanging 31 of the hole 2 is 5 mm, and the gap M between the two layers of filter plates 1 is 4 mm; in the two layers of filter plates 1, the width ratio of the wall 3 between the adjacent ventilation holes 2 on the upper filter plate 1 is ...

Embodiment 3

[0059] As shown in FIG. 9 , and referring to FIG. 4 to FIG. 6 , it is another preferred embodiment of the present invention. As shown in Figure 8, the oil fume filter device of this embodiment is basically the same as the oil fume filter device in Embodiment 1, the only difference is that the shape and relative size of the plate wall 3 between the adjacent ventilation holes 2 on the filter plate 1 are different. And the width and spacing of the ventilation holes 2 on the two layers of filter plates are different. Specifically: the cross-section of the wall 3 between adjacent ventilation holes 2 on the filter plate 1 in this embodiment is a straight line segment and arc-shaped flanging 31 extends at both ends of the straight line segment, and the upper layer filter plate 1 The upper layer of the ventilation hole 2 The width is 1mm, the height H of the flange 31 of the ventilation hole 2 1 is 2mm, the width of the ventilation hole 2 on the lower filter plate 1 is 8mm, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com