Method for measuring and controlling assembled air-conditioner dew point

A combined air conditioner and dew point temperature technology, which is applied in heating and ventilation control systems, heating methods, and material moisture content, can solve problems such as waste of energy consumption, lower reliability, and damage to humidity sensors, and achieve secondary heating savings , Eliminate coupling errors, control precise and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

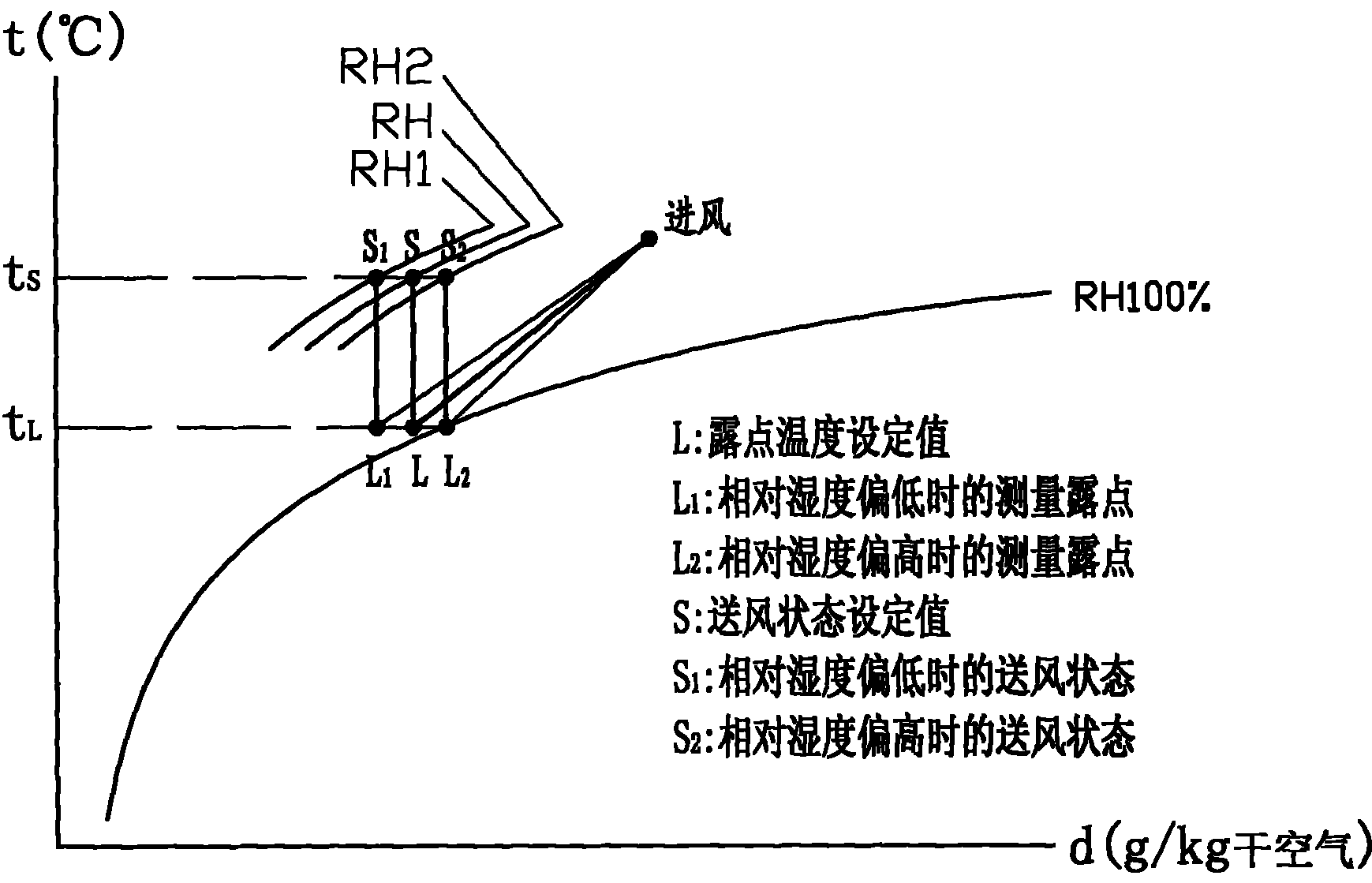

[0047] With reference to accompanying drawing, the present invention will be described in detail below:

[0048] The method for measuring and controlling the dew point temperature of a combined air conditioner comprises the following steps:

[0049] (1) Read the measured values of the temperature and relative humidity sensors set at the control target point:

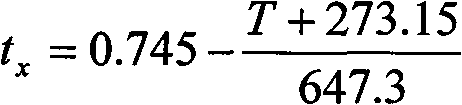

[0050] (2) The dew point temperature measurement value corresponding to the temperature and relative humidity measurement value of the control target point, and the dew point temperature setting value corresponding to the temperature and relative humidity setting value are obtained by the controller according to the following formula:

[0051] Formula (1):

[0052] Td = b × ( log ( RH ) + a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com