Detonator excimer and detonator therewith

A technology of detonator and charge density, which is applied in the direction of weapon accessories, fuzes, offensive equipment, etc., can solve the problems of unfavorable safety production, undiscovered detonator excitation device, detonation detonator production, etc., to achieve standardized operation and facilitate continuous large-scale industry The effect of producing and guaranteeing the quality of detonators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

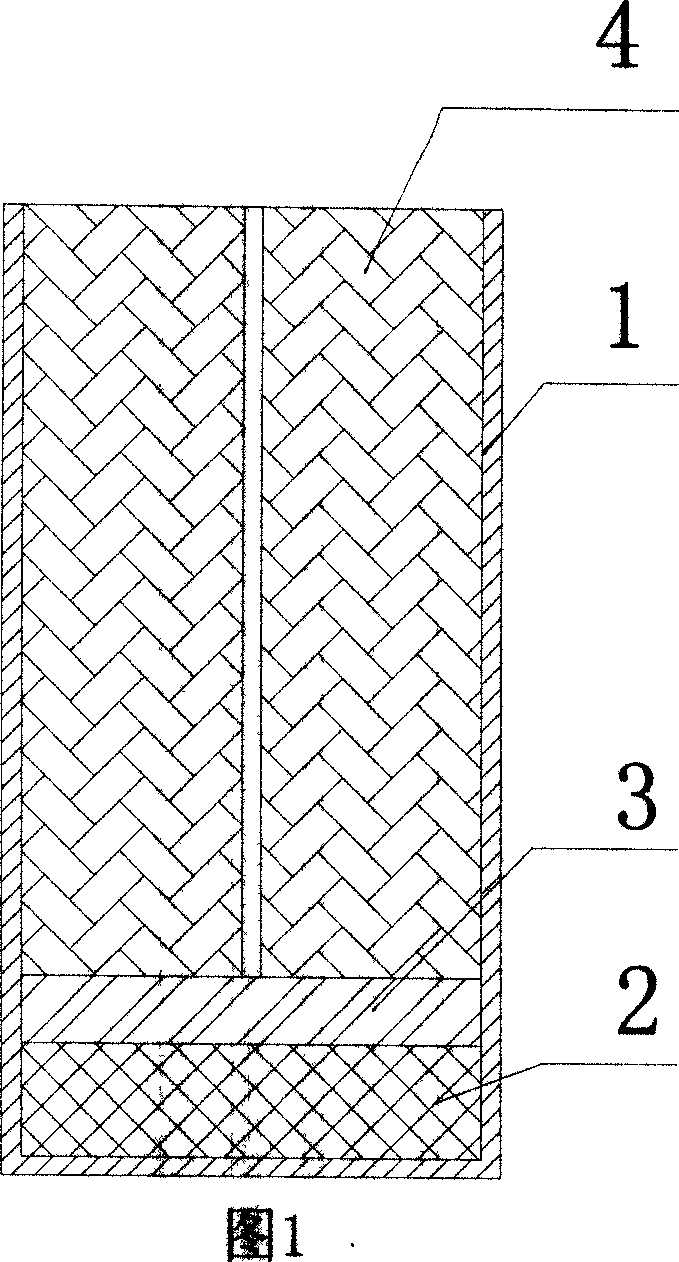

[0026] In Fig. 1, 1 is a cylindrical shell, made of aluminum, with a smooth surface, no cracks and blisters, and its molding dimensions are: outer diameter 10mm, wall thickness 1mm, height 25mm. The shell is filled with secondary explosive 2, ignition powder 3 and fire transmission element 4 sequentially from bottom to top, secondary explosive 2 is RDX with a density of 1.0g / cm 3 , the filling height is 5mm. Ignition powder 3 is made up of combustible agent, oxidizer and binding agent, and filling height is 4mm, and wherein combustible agent is magnesium powder, and content is 20%, and oxidizer is red lead (Pb 3 o 4 ), the content is 80%, the adhesive is a shellac solution with a concentration of 4%, and the content is 2 times of the total content of the combustible agent and the oxidizing agent. The fire transmission element 4 is a cylinder made of lead metal, with an outer diameter of 9.2mm and a height of 16mm. Its outer cylindrical surface is in interference fit with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com