Hot-pipe solar cooker of optical lens

A technology for solar cookers and optical mirrors, applied in solar thermal devices, solar thermal energy, solar thermal power generation, etc., can solve the problems of inability to achieve high heat flux density thermal energy transfer, inability to achieve solar energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

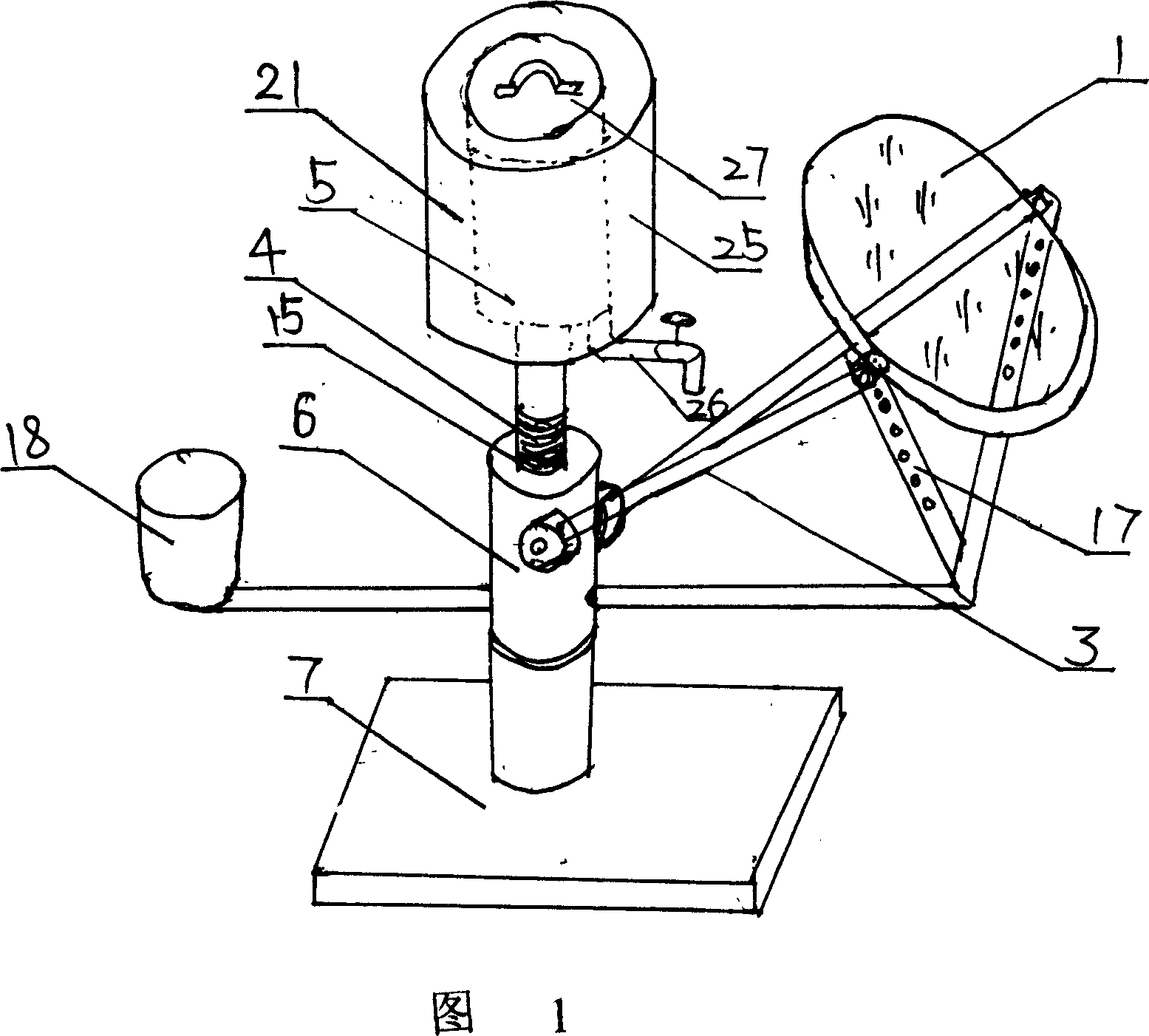

[0053] Example 1: Manual solar cooker with disc heat pipe

[0054] It is a 1.2-meter Fresnel lens (1) with a diameter of 1.2 meters. The evaporation end of the heat pipe solar cooker (21) is a heat pipe with a diameter of 38MM, and its condensation end is a groove of a concave shape (5). (25), a pipeline (26) connected to the outside is provided at its bottom, and a switch is provided on the pipeline so that the liquid flows out; this solar cooker adopts a manual tracking method, and the rotation axis (6) is rotated horizontally to adjust the series of holes ( 17) To adjust the height, the intermittent or simultaneous rotation axis uses a series of holes to track the sun. During the rotation of the optical mirror and the counterweight along the axis, the heat pipe solar cooker is stationary relative to the ground. This structure effectively realizes Tracking of solar energy;

Embodiment 2

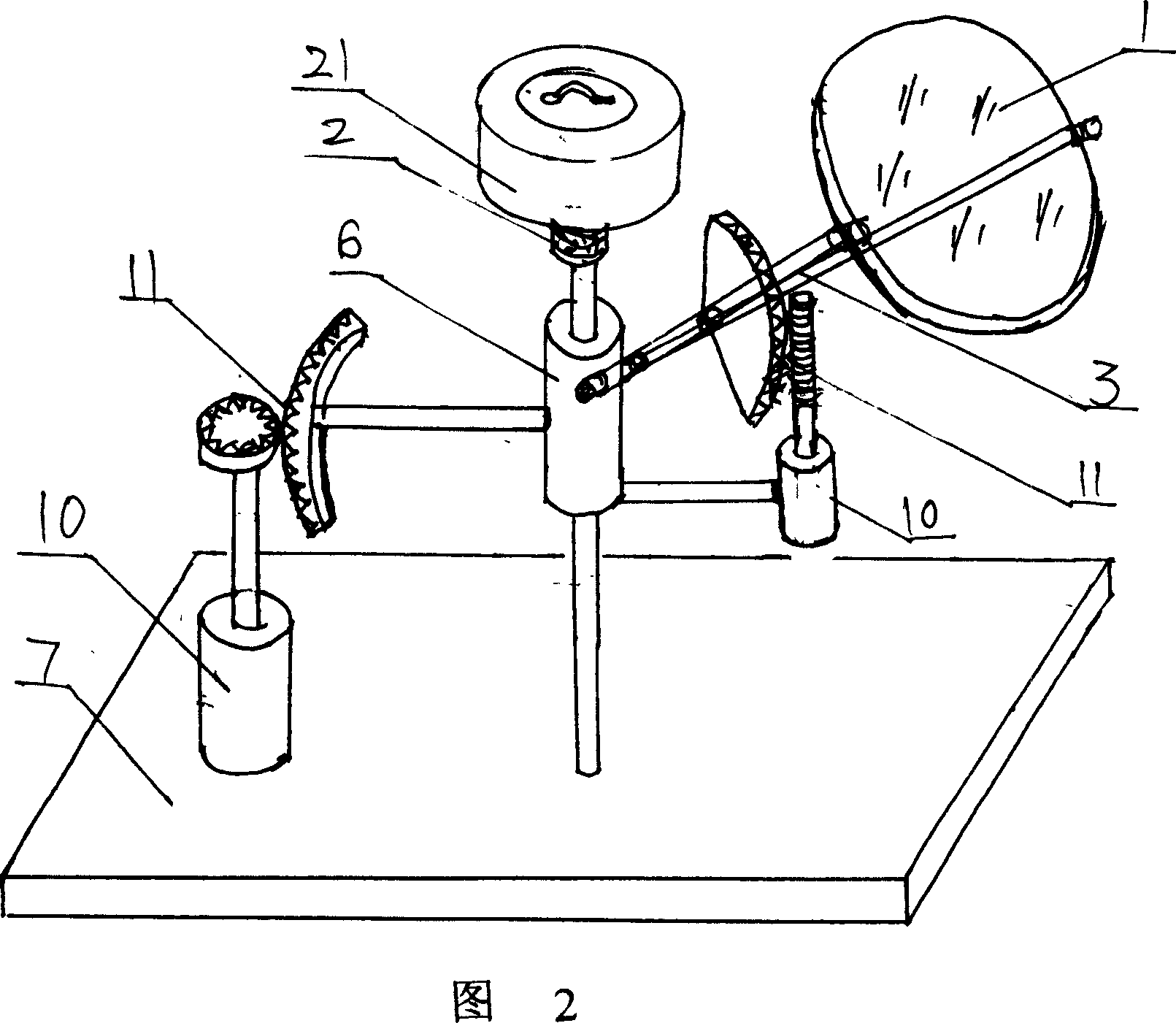

[0055] Embodiment 2: The disc heat pipe automatically tracks the solar cooker

[0056] A disc-type solar cooker with an automatic tracking system, the solar cooker also adopts a heat pipe solar cooker structure, the same as in Embodiment 1, its tracking system adopts an arc-shaped gear processed on the horizontal rotating shaft (6), and uses the motor (10) to As the driving force, it is connected by a worm gear structure to realize the driving of the horizontal axis. An arc-shaped gear is installed on the optical mirror bracket, which is also connected by a worm gear structure to realize the drive in the height direction. The electrode is fixed on the shaft (6). and rotate simultaneously with the axis;

Embodiment 3

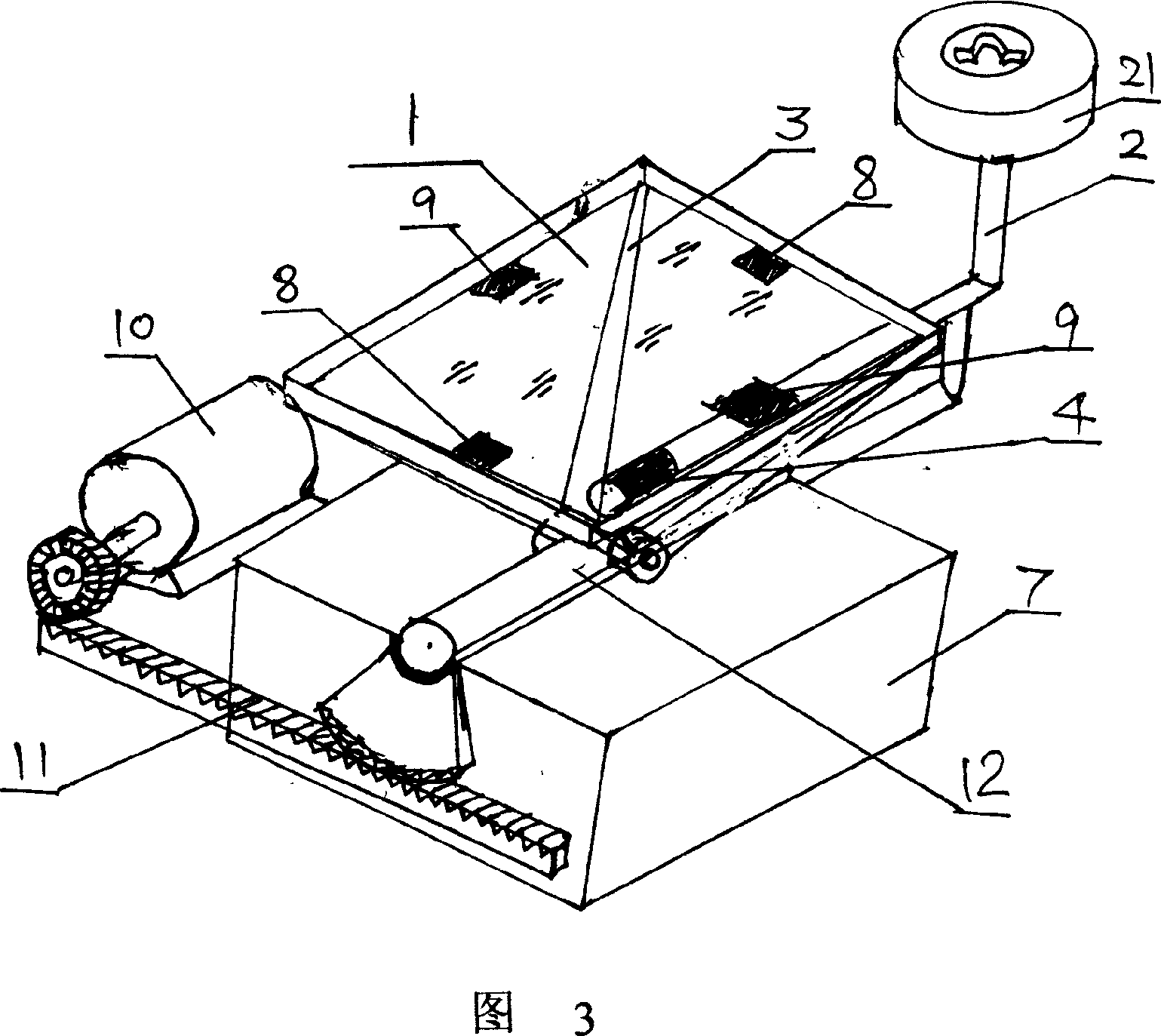

[0057] Embodiment 3: Table type cross semi-automatic tracking solar cooker

[0058] The table-type cross semi-automatically tracks the solar cooker, the structure of which is the same as the first embodiment, the optical mirror adopts a quadrilateral Fresnel lens 3, which is fixed on a mutually perpendicular axis 12 to form a funnel structure, and the solar cooker The evaporation end of the heat pipe is set at the crossing area of the two axes, and the heat utilization material is arranged at the evaporation end 4, and four sensors are arranged on the lens, and there are two sensors in the X direction and the Y direction respectively. The value of the sensor is used to adjust the lens, and the gear mechanism 11 is used to adjust and control the axis in the X direction. The motor is used as the driving part, and the Y direction is manually tracked. The overall system is installed on a table, so it is called Cross semi-automatic solar cooker tracking system;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com