Nitrogen oxide compound fluorescent material and illuminating or displaying light source therefrom

A technology of nitrogen oxides and luminescent materials, applied in luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of poor chemical and thermal stability of sulfide phosphors, pollute the environment, exhaust gas, etc., and achieve easy realization Mass production, high energy conversion, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

Example 1: Sr 0.90 Mg 0.06 Si 2 o 2 N 2 :Eu 0.04 Preparation example of luminescent material

Weigh SrCO3 (53.48 grams), ZnO (1.95 grams), Si3N4 (29.12 grams), SiO2 (11.80 grams), Al2O3 (0.82 grams) and Eu2O3 (2.83 grams) according to the above composition, add n-hexane or absolute ethanol to mix and grind After uniformity, N2 / H2 (95% / 5%) was introduced under normal pressure, the flow rate was 2 liters / minute, and 0.1gSrF2 was used as a flux, and it was kept at 1400°C for 4 hours. The condition is to bake again at high temperature to promote the development of grains. The obtained luminescent material was pulverized, washed with hydrochloric acid to remove impurities, and dried to obtain 100 g of the green luminescent material of the present invention. Its X-ray diffraction pattern is shown in Fig. 2, and it can be seen from the figure that the powder mainly contains a crystal phase (greater than 95wt%) having the same diffraction pattern as SrSi2O2N2. Its emission and ...

Example Embodiment

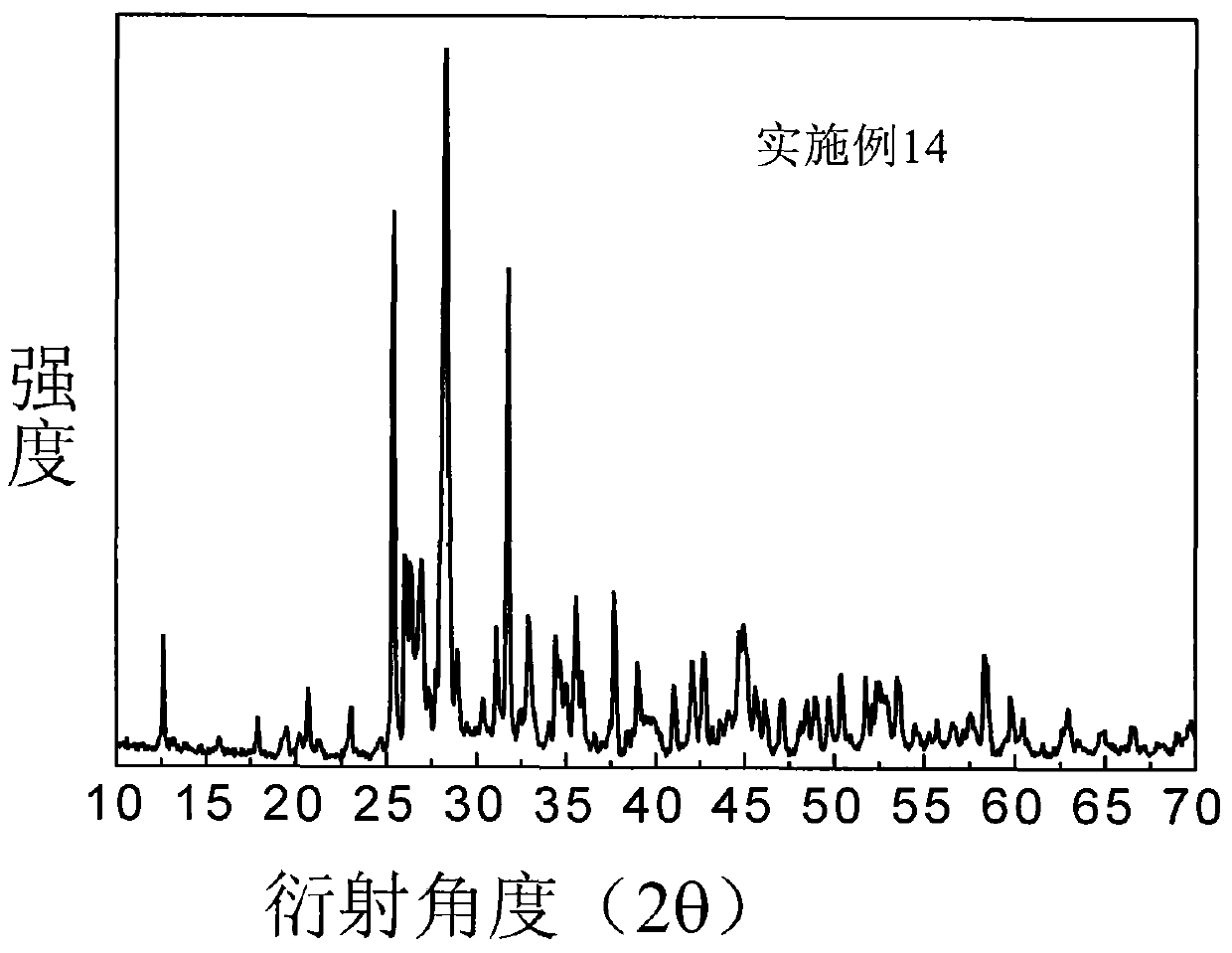

Example 14: Sr 0.90 Zn 0.06 Si 1.96 al 0.04 o 2.04 N 1.96 :Eu 0.04 Preparation example of luminescent material

Weigh SrCO3 (53.48 grams), ZnO (1.95 grams), Si3N4 (29.12 grams), SiO2 (11.80 grams), Al2O3 (0.82 grams) and Eu2O3 (2.83 grams) according to the above composition, add n-hexane or absolute ethanol to mix and grind After uniformity, N2 / H2 (95% / 5%) was introduced under normal pressure, the flow rate was 2 liters / minute, and 0.1gSrF2 was used as a flux, and it was kept at 1400°C for 4 hours. The condition is to bake again at high temperature to promote the development of grains. The obtained luminescent material was pulverized, washed with hydrochloric acid to remove impurities, and dried to obtain 100 g of the green luminescent material of the present invention. Its X-ray diffraction pattern is shown in Fig. 2, and it can be seen from the figure that the powder mainly contains a crystal phase (greater than 95wt%) having the same diffraction pattern as SrSi2O2N2....

Example Embodiment

Example 2-22:

The corresponding raw materials are weighed according to the chemical formula listed in each embodiment in Table 1-2 and the stoichiometry, the preparation process is the same as in Example 1, wherein the reaction flux used is chloride or fluoride of A, and the obtained The luminous intensity of the luminescent material is shown in Table 1.

The chemical formula and its luminescent characteristics (excitation wavelength is 450nm) of table 1 embodiment 1-18 embodiment chemical formula emission main peak nm relative intensity % 1 Sr 0.90 Mg 0.06 Si 2 o 2 N 2 :Eu 0.04 539 92 2 Sr 0.90 Ca 0.06 Si 2 o 2 N 2 :Eu 0.04 545 98 3 Sr 0.90 Ba 0.06 Si 2 o 2 N 2 :Eu 0.04 540 103 4 Sr 0.90 La 0.04 Si 2 o 2 N 2 :Eu 0.04 542 85 5 Sr 0.90 Gd 0.04 Si 2 o 2 N 2 :Eu 0.04 542 84 6 Sr 0.90 Lu 0.04 Si 2 o 2 N 2 :Eu 0.04 545 95 7 Sr 0.90 Y 0.04 Si 2 o 2 N 2 :Eu 0.04 542 92 8 Sr 0.94 Li 0.04 Si 2 o 2 N 2 :Eu 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com