Fuse supporter for power

A technology of fuses and supporters, which is applied in the direction of circuits, electrical components, emergency protection devices, etc., and can solve problems such as danger, damage, and low strength of power fuses 3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

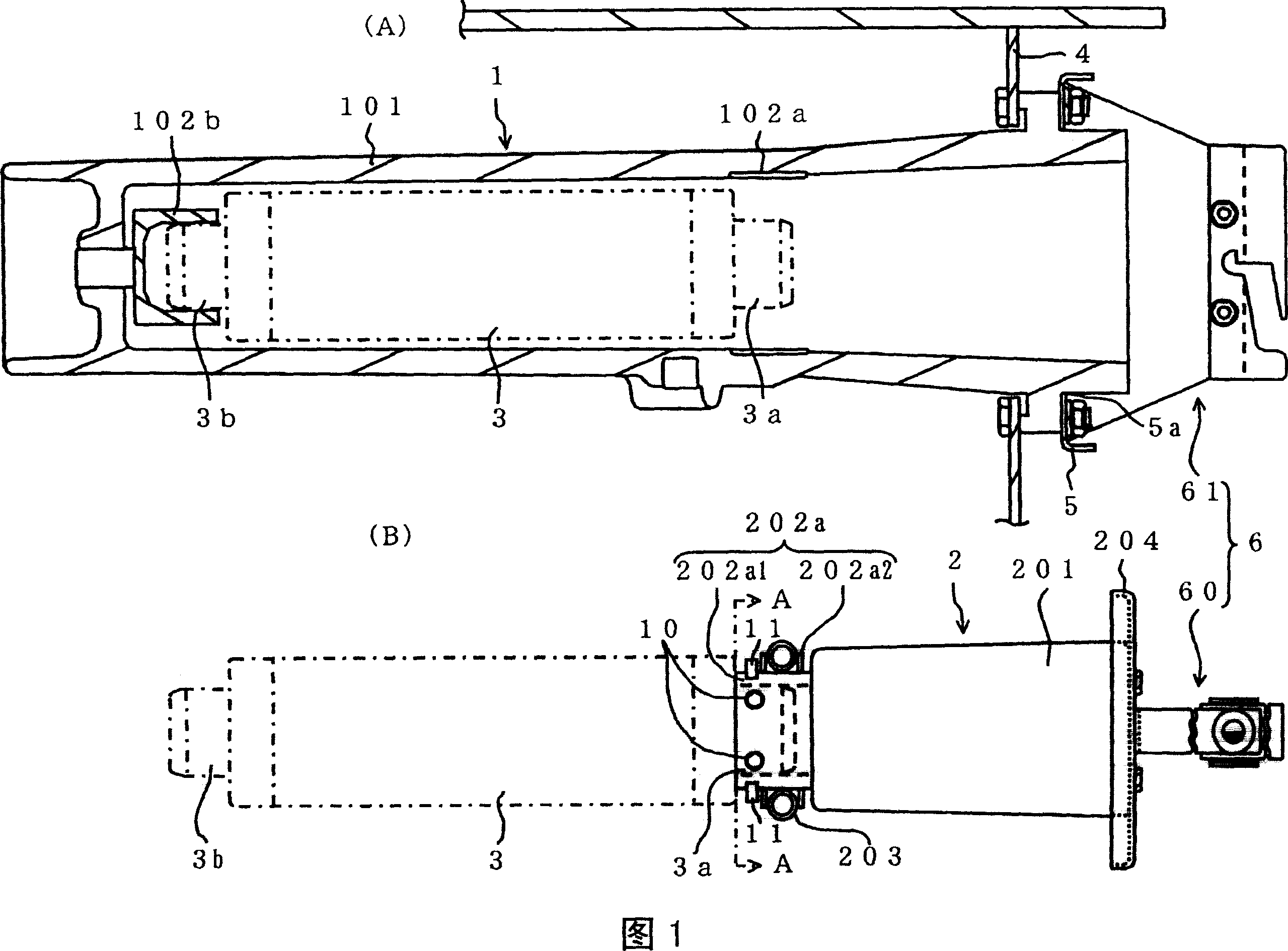

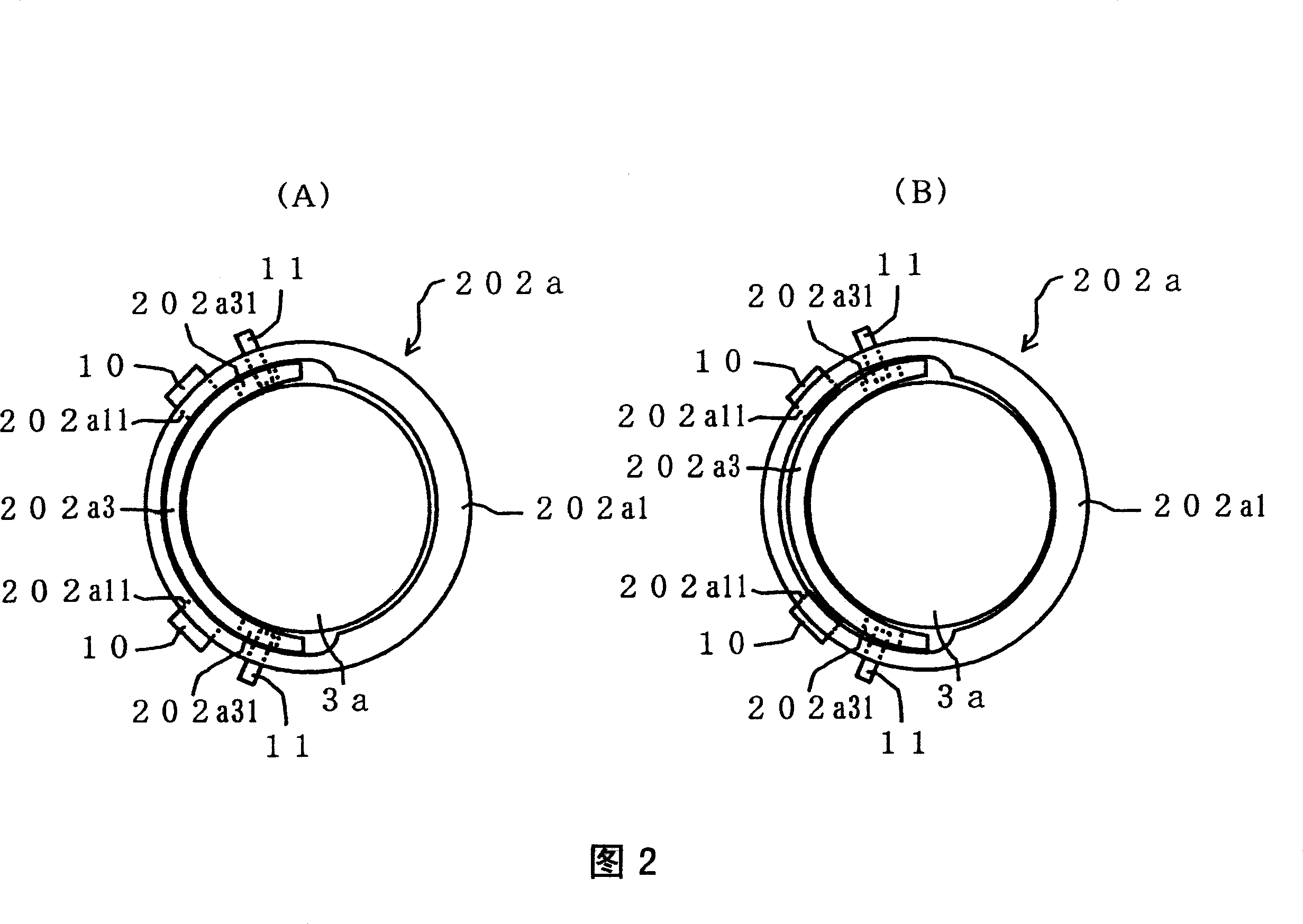

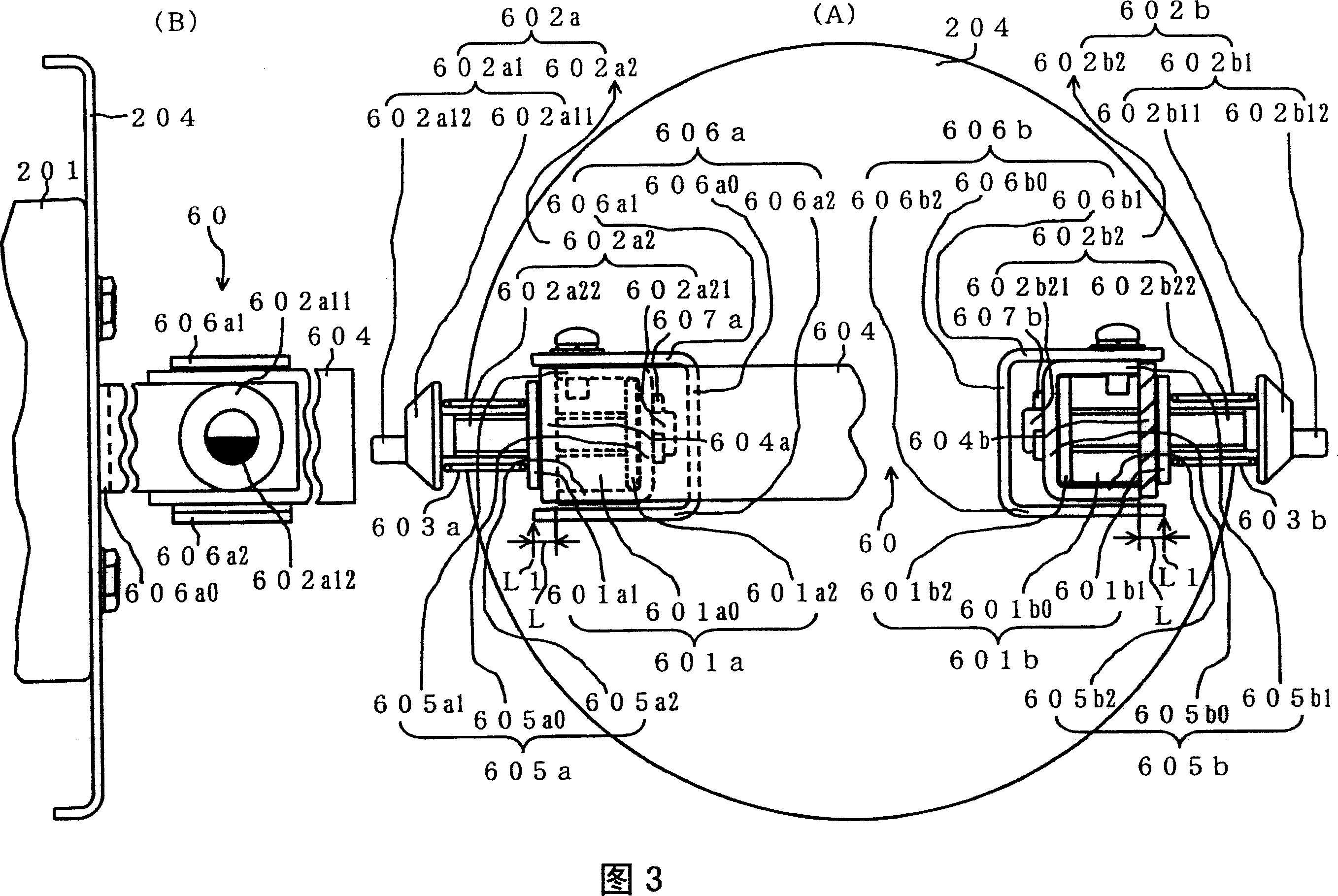

[0065] 1(A) is a longitudinal sectional view showing an embodiment of a fuse housing body constituting the electric fuse holder according to the present invention, and (B) is a view showing an electric fuse constituting the electric fuse holder according to the present invention. Side view of an embodiment of the grip body.

[0066] As shown in the figure, the power fuse housing body 1 is composed of an insulating cylindrical member 101 having a bottom and first and second fixed-side electrodes 102a, 102b, and is completely housed along the longitudinal direction of the cylindrical member 101. For example, a ring-shaped first fixed-side electrode 102a is attached to the inner peripheral surface of the power fuse 3 at a position facing the first (opening side of the cylindrical member 101) electrode 3a. In the state of being completely accommodated along the longitudinal direction of the cylindrical member 101, the inner peripheral surface of the position facing the second (bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com