Flour measuring and coutrolling method for electromagnetic valve

A measurement and control method and a solenoid valve technology are applied in the control field of the automation technology field, and can solve the problems of increasing the control output lag time, large measurement error, and inability to realize continuous control of the solenoid valve opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and gives detailed implementation and specific operation procedures, but the protection scope of the present invention is not limited to the following implementations example.

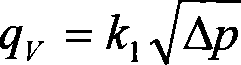

[0011] This embodiment is implemented based on a flow measurable and controllable system. The system includes a flow measurable and controllable solenoid valve, a signal processing controller and power electronic switching devices. The flow measurable and controllable solenoid valve includes a solenoid valve body, a valve, a compression spring, and an electromagnet. , Pressure guiding hole pipe, differential pressure sensor, leak-proof rubber gasket, plastic soft pressure plate and cable interface, valve, compression spring, leak-proof rubber gasket, electromagnet, differential pressure sensor, plastic soft pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com