Experiment method for packer working performance and apparatus thereof

An experimental method and packer technology, applied in measuring devices, sealing/packing, instruments, etc., can solve problems such as gaps in packer systems, and achieve the effects of small initial investment, simple structure, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

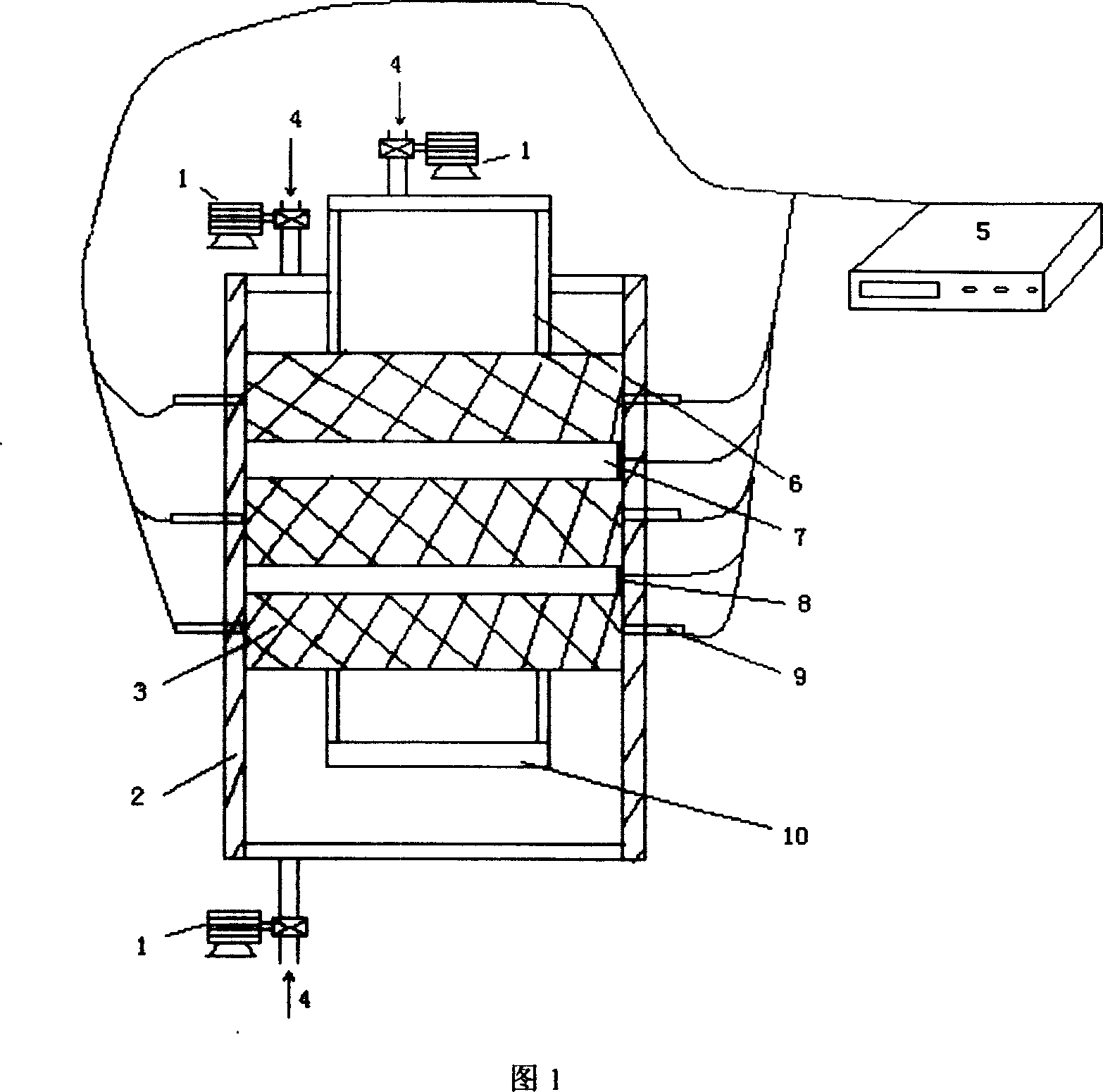

[0018] 1. Experimental packer: Y341-148 type packer

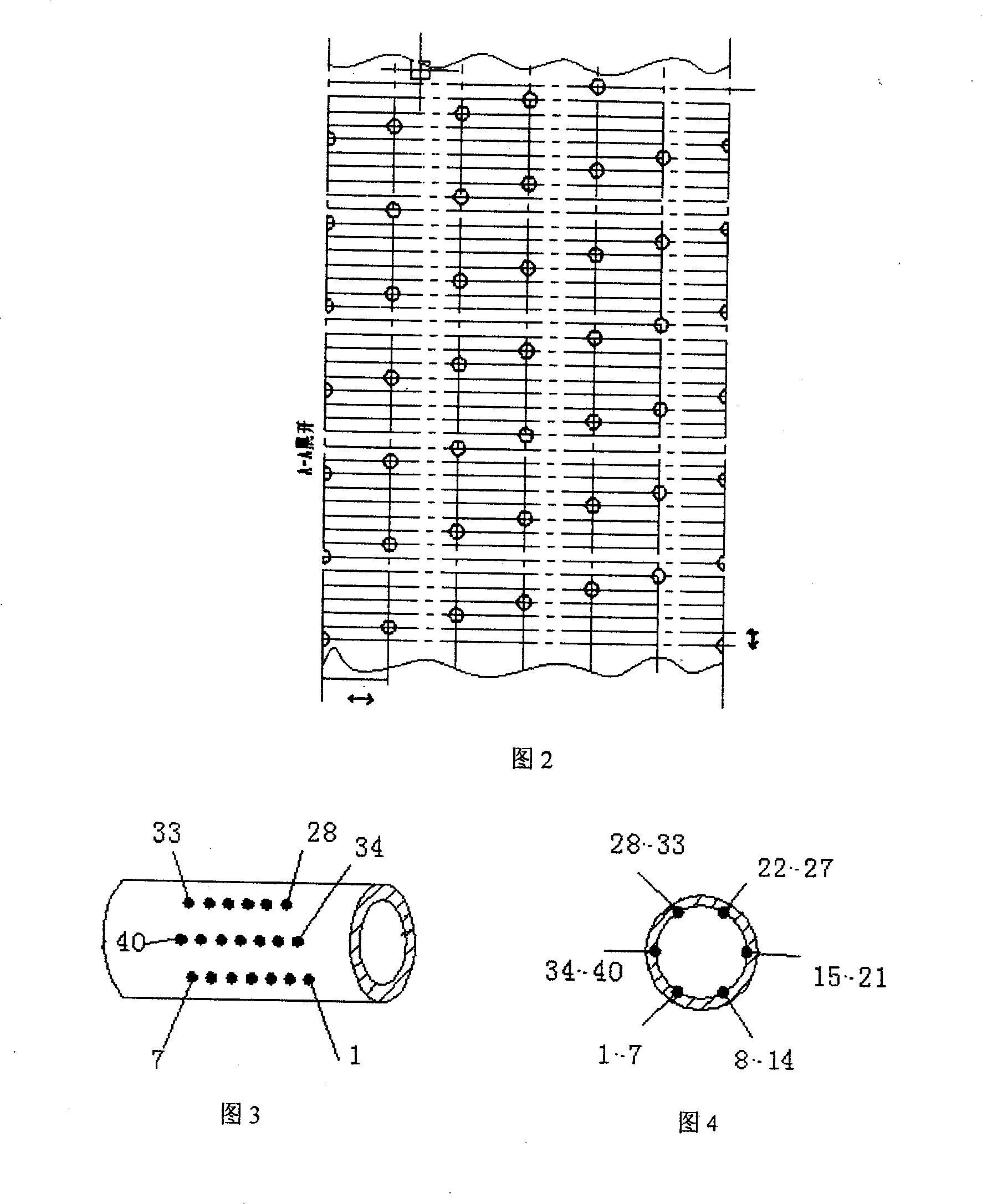

[0019] 2. Manufacture of experimental casing: 7in casing is processed. The length of the test casing is 1200mm. From the top to the bottom of the casing, a hole with a diameter of Ф10 is drilled in a spiral shape every 10mm in the axial direction and every 60° in the circumferential direction within the length of 400mm, a total of 40 holes.

[0020] 3. Install the displacement sensor on the spacer ring of the Y341-148 packer. The packer is connected with a plug at the bottom and a tubing hanger at the top.

[0021] 4. Install the pressure sensor. The mandrel of the pressure sensor penetrates through the small hole of the test casing, and the end face of the mandrel is flat with the wall of the casing, and a total of 40 pressure sensors are distributed.

[0022] 5. The upper and lower joints of the center pipe of the packer and the test casing are respectively connected to electric pressure test pumps.

[0023] 6. With a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com