Automobile internal decorative piece and making method

A technology for automobile interior parts and fixing buckles, which is applied in the direction of connecting members, thin plate connections, superstructures, etc., can solve the problems of high production cost of interior parts, unsatisfactory bonding effect, and expensive adhesive, etc. High bond strength, reduced production cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

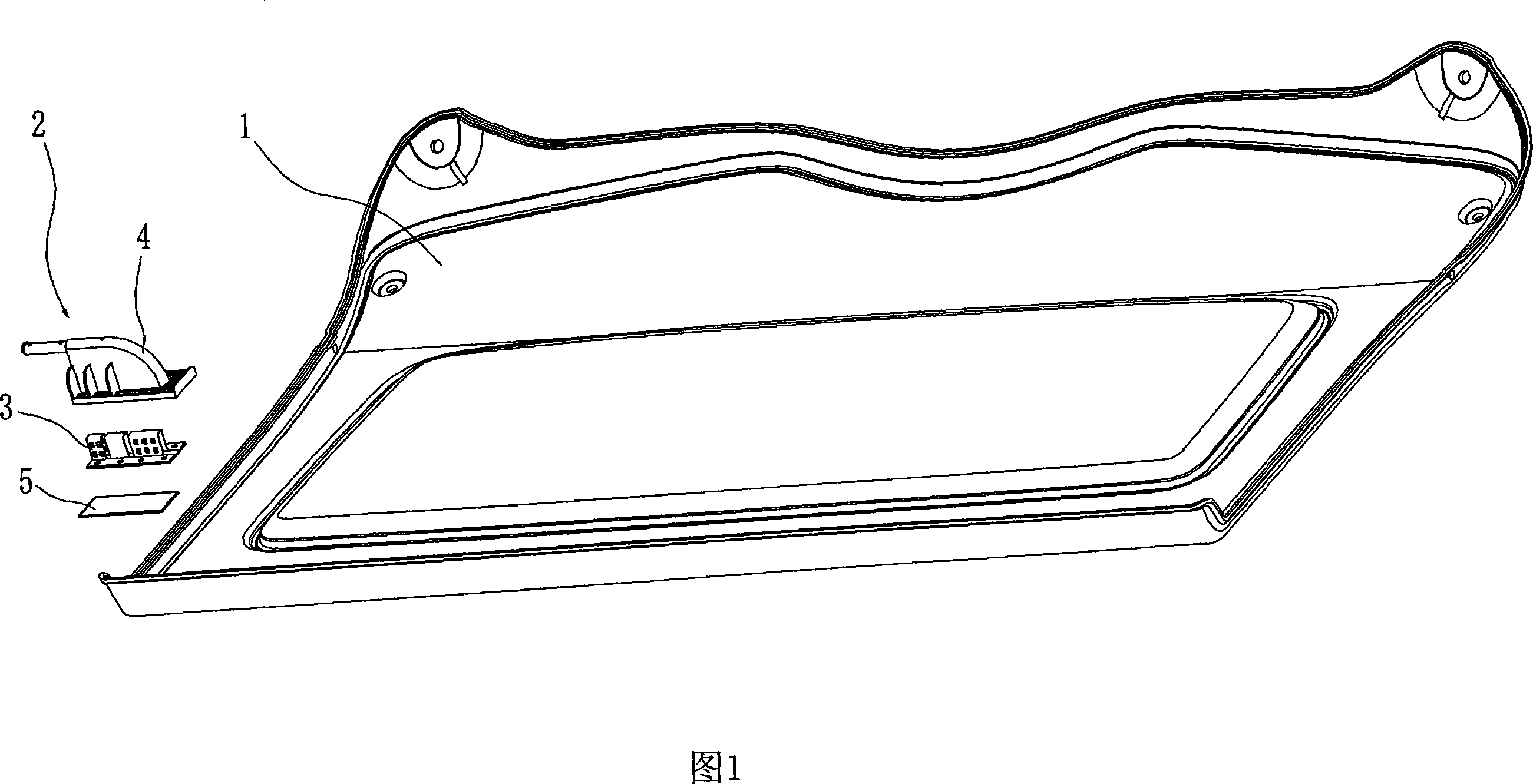

[0028] As shown in Fig. 1 to Fig. 8, it is a preferred embodiment of the present invention. As shown in Figures 1 to 8, the automotive interior parts in this embodiment have a skeleton base material 1 and a fixing buckle 2 whose surface layer is non-woven fabric, and the fixing buckle 2 includes a metal buckle 3 with a bottom plate 31 and a fixing buckle 2. The plastic buckle 4 is connected to the metal buckle 3 , and the bottom plate 31 of the metal buckle 3 is provided with counterbore-like holes 32 with a large upper part and a smaller lower part. Between the skeleton base material 1 and the bottom plate 31 of the metal buckle 3 is provided a wood powder board 5 containing polypropylene which is slightly larger than the bottom plate 31 of the metal buckle. The composite of the skeleton base material 1 and the wood powder board 5 is formed by pressing in a softened state, and the wood powder board 5 is pressed in the softened state to fill up the holes on the metal buckle bo...

Embodiment 2

[0036] As shown in Figure 9, and referring to Figures 1 to 8, the automotive interior part of this embodiment has a skeleton base material 1 with a carpet surface and a fixed buckle 2, and the fixed buckle 2 includes a metal buckle with a bottom plate 31 3 and the plastic buckle 4 fixed on the metal buckle 3 , the bottom plate 31 of the metal buckle 3 is provided with a hole 33 . A polypropylene plate 6 having the same size as the bottom plate 31 of the metal buckle is disposed between the skeleton base material 1 and the bottom plate 31 of the metal buckle 3 . The composite of the skeleton base material 1 and the polypropylene plate 6 is formed by pressing in a softened state, and the part of the polypropylene plate 6 enters the hole 33 due to being pressed in the softened state and is buckled at the mouth of the hole 33. The outer edge of the part, and thus the skeleton base material 1, the polypropylene plate 6 and the metal buckle 3 are fixed as a whole.

[0037] The meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com