Tyre turning mechanism

A technology of overturning mechanism and tires, which is applied in the direction of motor vehicles, conveyor objects, transportation and packaging, etc. It can solve the problems of inconvenient gripping by manipulators, and achieve the effect of compact structure and simple action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

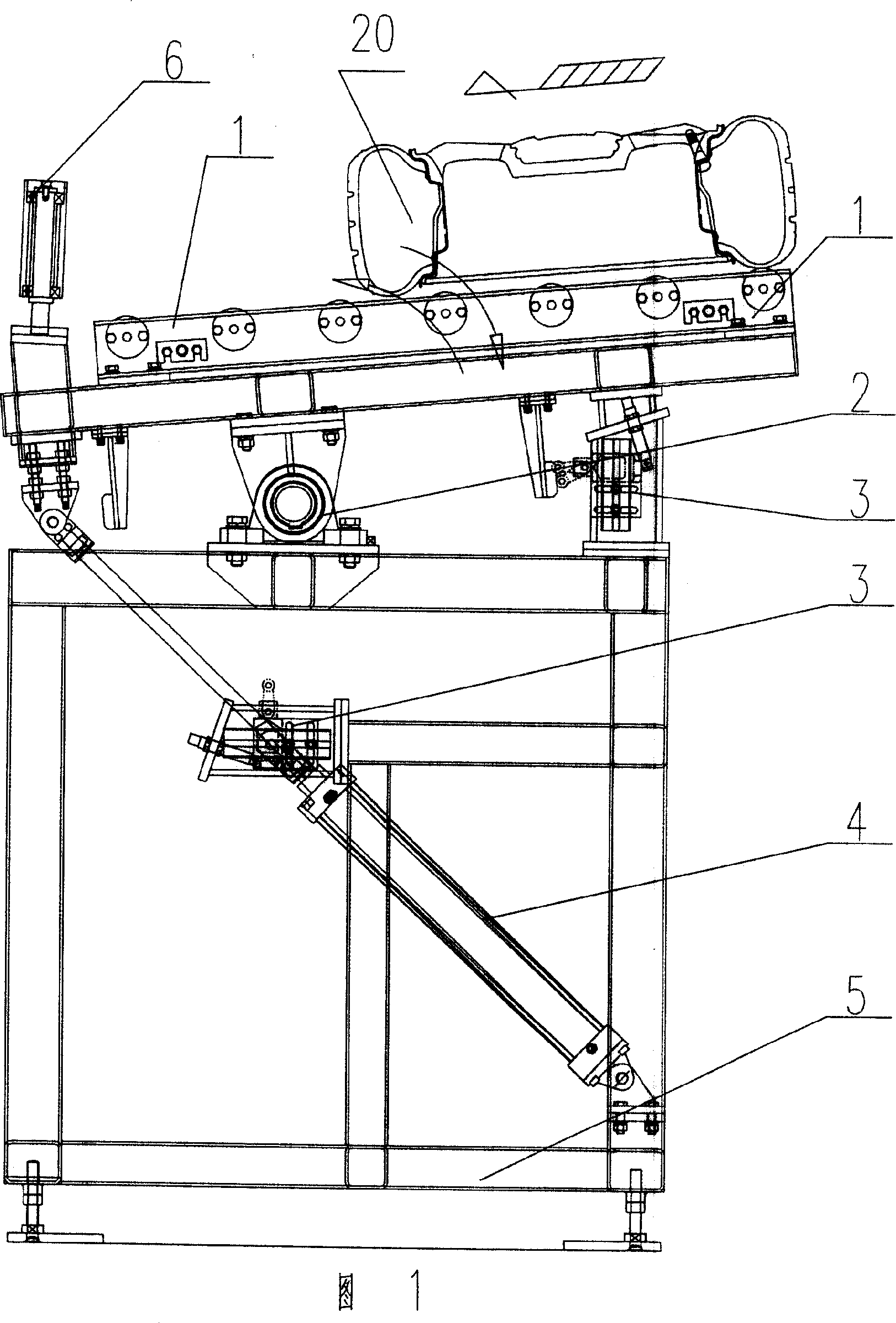

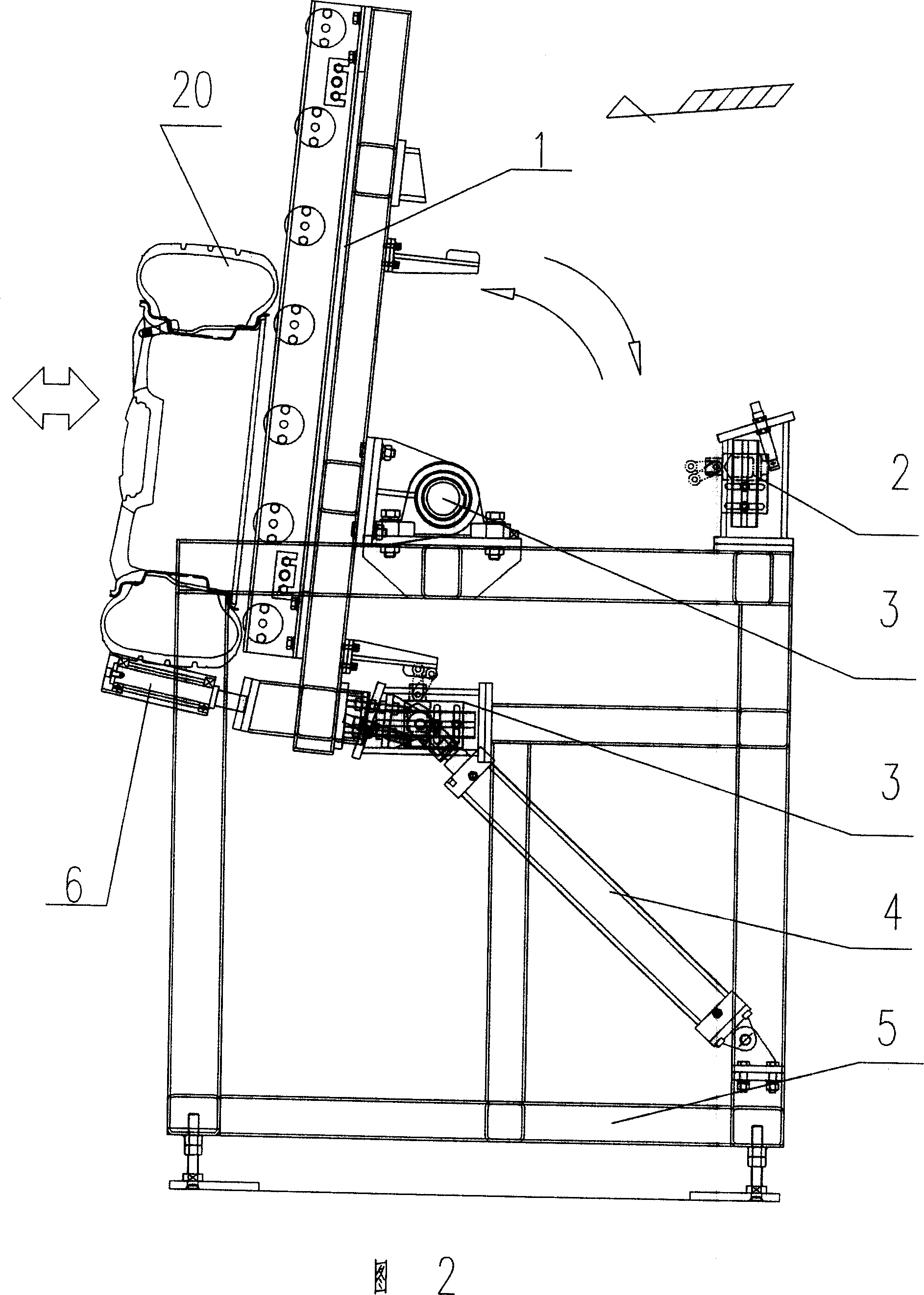

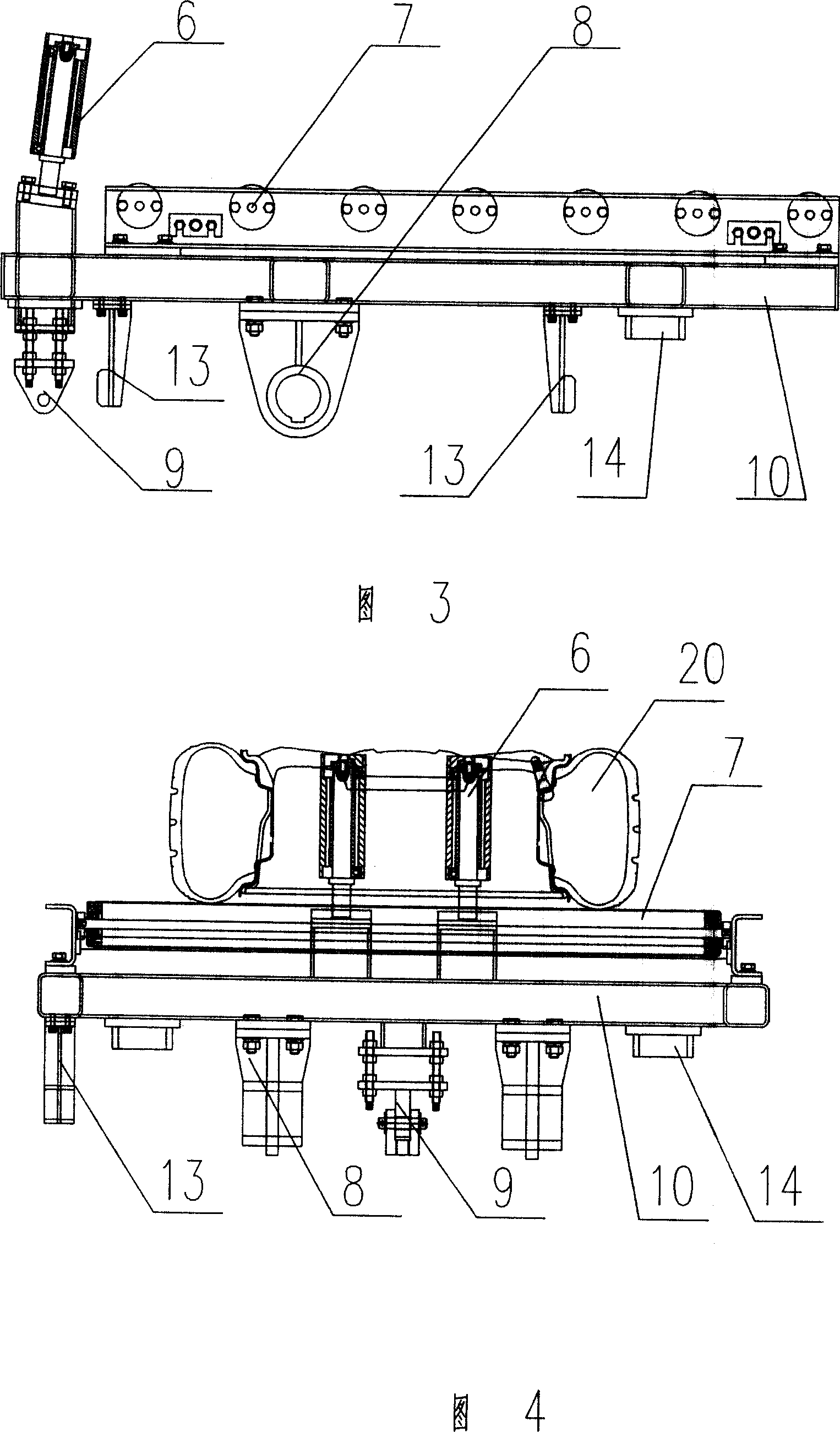

[0016] In the accompanying drawings, 1 is an overturn frame, 2 is a shaft seat, 3 is a detection limit device, 4 is a cylinder, 5 is a frame, 6 is a limit roller, 7 is a non-powered roller table, 8 is a rotating support, 9 Is the cylinder installation support, 10 is the installation frame, 11 is the bearing with seat, 12 is the shaft, 13 is the contact plate, 14 is the limit plate, 15 is the pneumatic buffer, 16 is the detection switch, 17 is the detection limit device Mounting seat, 18 is a support frame, and 19 is an adjustment foot.

[0017] As shown in the figure: the overturning frame 1 is hinged above the frame 5, and the cylinder 4 is hinged under the frame 5. The piston rod of the cylinder 4 is hinged with the front end of the overturning frame 1, and several Two roller tables 7 parallel to each other, a limit roller 6 is arranged on the front end of the reversing frame 1, and a detection limit device is set under the rear end of the reversing frame 1. During work, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com