Condensing heat exchanger

A heat exchanger and condensing technology, which is applied in the field of heat exchange devices, can solve the problems of inability to condense and release heat, large smoke loss, and reduce thermal efficiency, and achieve the effects of simple structure, reduction of harmful gases, and improvement of thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

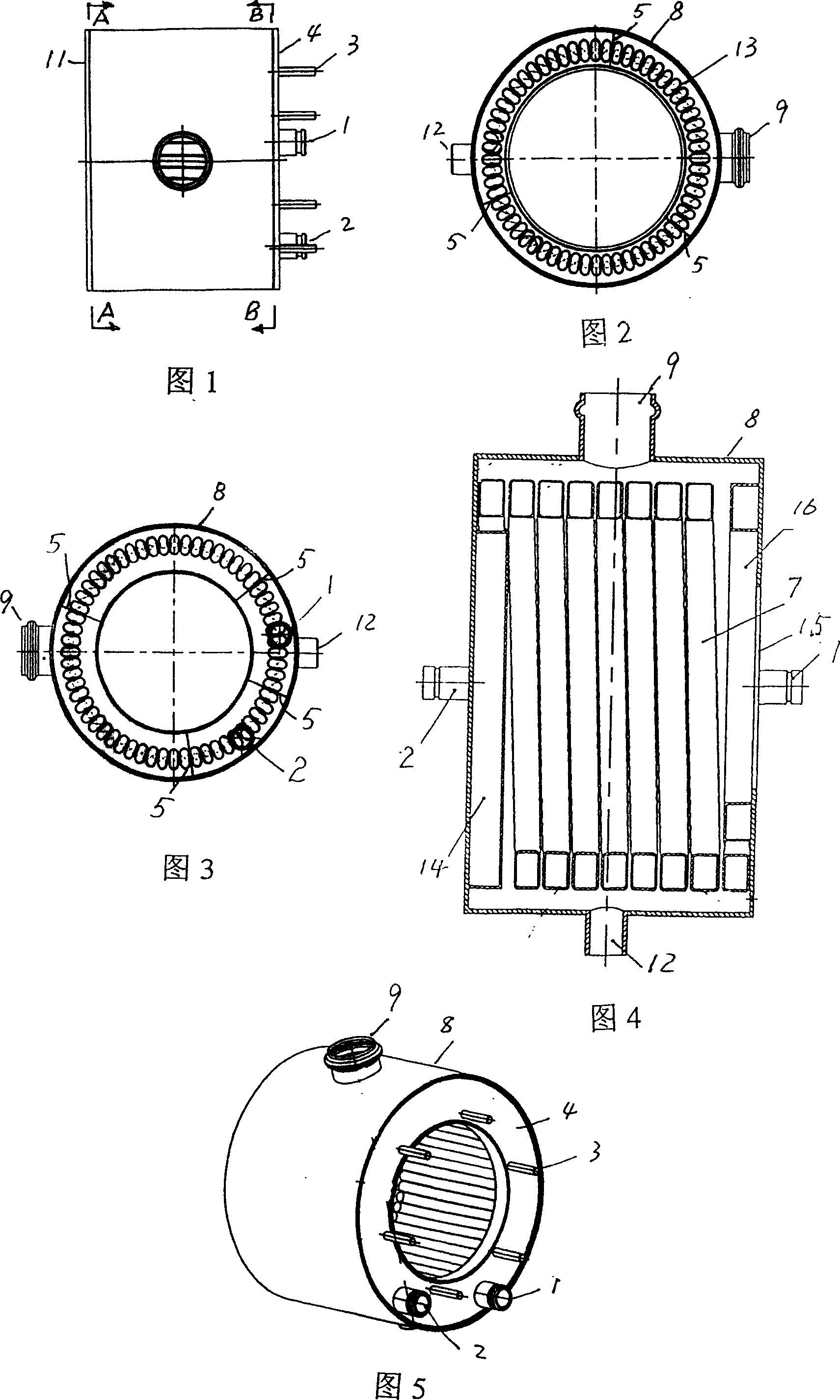

[0020] The condensing heat exchanger for a wall-mounted boiler consists of a heat-absorbing tube 7 spirally coiled to form a heat-absorbing cylindrical cylinder 13. The two ends of the heat-absorbing tube are respectively connected to the water outlet cavity 14 and the water inlet cavity 16. The cavity 14 and the water inlet cavity 16 are located in the shell 8, and there is a gap of 10-20mm between the outer wall of the cylinder body 13 and the inner wall of the shell 8, and the water outlet joint 2 and the water inlet joint 1 are connected to the water outlet cavity 14 and the water inlet cavity 16 respectively. Connection, the casing has a burner installation hole 15, through which the burner is installed in the barrel 13, the upper end of the casing is connected to the smoke outlet 9, and the lower end is connected to the condensed water outlet 12.

Embodiment 2

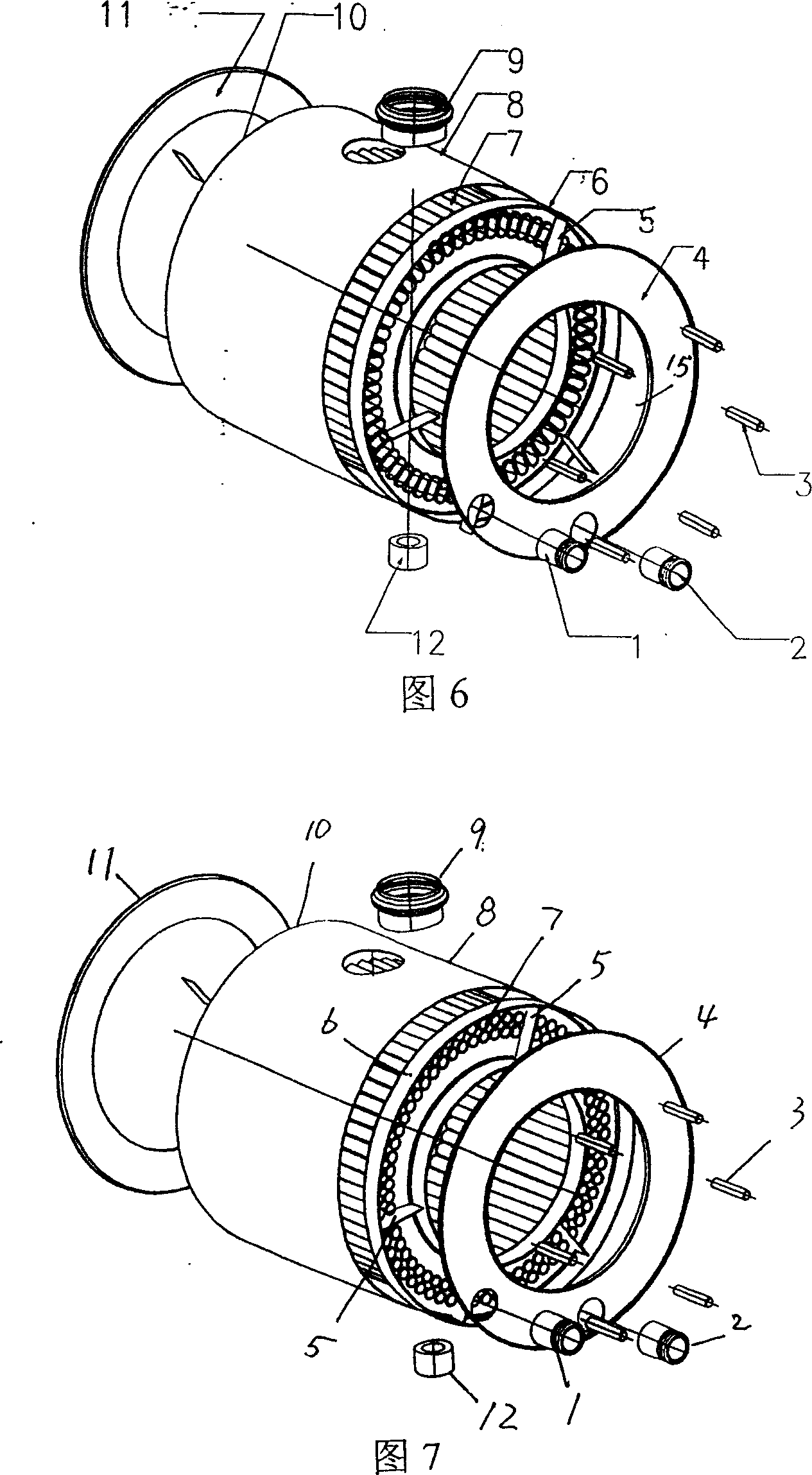

[0022] Some straight heat-absorbing pipes 7 are arranged in one layer or two layers to form cylinder body 13, arranged into one layer of heat-absorbing pipes with elliptical cross-section, and two-layer heat-absorbing pipes with circular cross-section. The two ends of the cylinder body respectively pass through the bottom surfaces of the front fixed plate 6 and the rear fixed plate 10 to be welded thereto. The front and rear fixing plates are ring-shaped, and their axial cross-section is groove-shaped. They are respectively welded with the ring-shaped front cover plate 4 and the circular rear cover plate 11 to form the front and rear water chambers. There are four water baffles 5 in the front water chamber. It is divided into four sub-water chambers, one of which communicates with the water inlet joint 1, and the other communicates with the water outlet joint 2. The hole in the middle of the front cover plate 4 is a mounting hole 15, and 6 burner mounting screws 3 are evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com