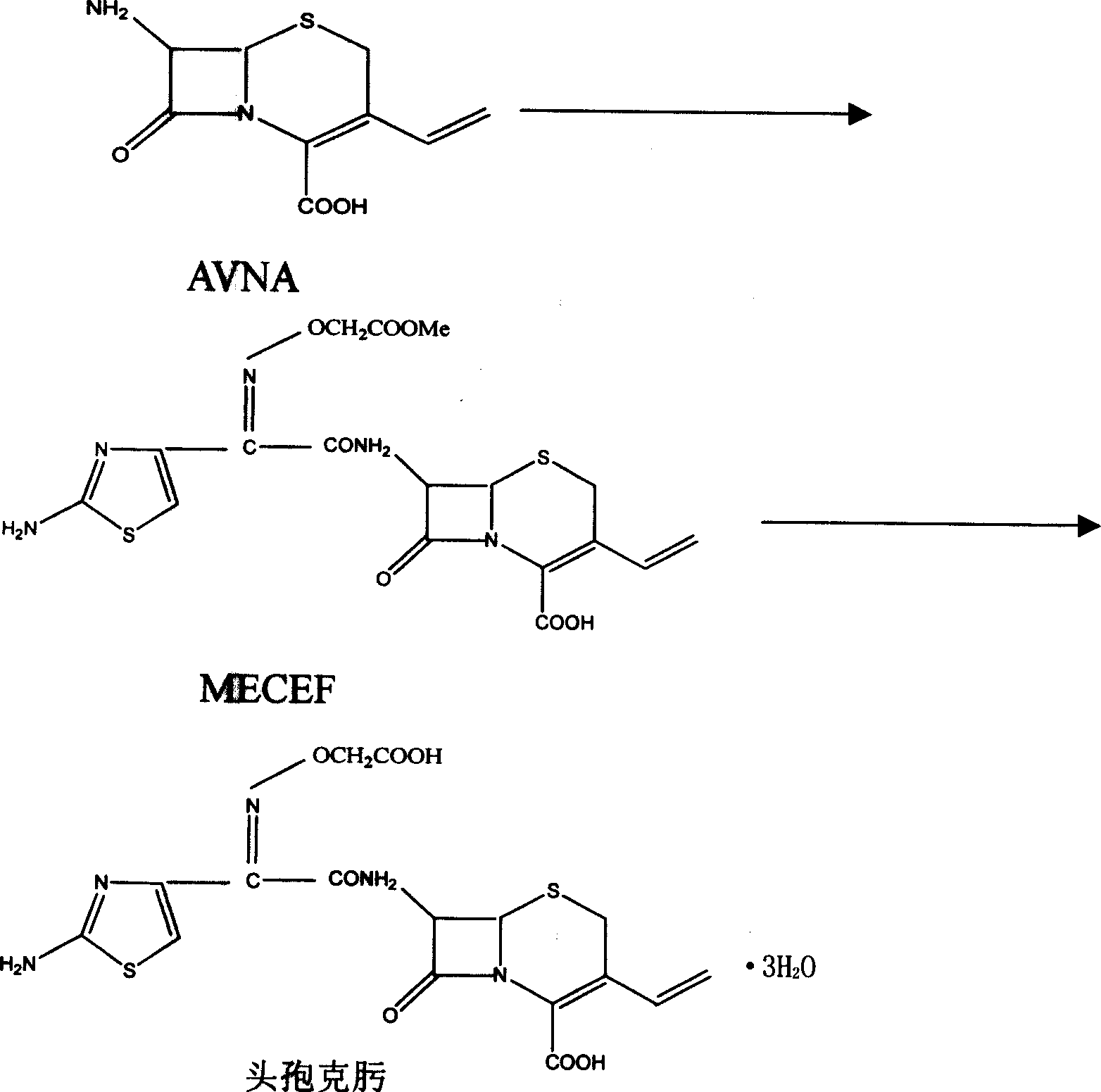

Method of synthesizing cefixime

A synthesis method and technology of cefixime, applied in the field of cefixime, can solve problems such as poor quality and low yield, and achieve the effects of improving yield, improving quality and yield, and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 300L of dichloromethane, 40kg of MICA-active ester into a clean reaction tank, add 25kg of AVNA, 100L of pure water, and 26L of triethylamine after dissolving, keep the temperature at 10°C, and react for 5.5 hours;

[0033] (2) Add 560L of ethyl acetate after the reaction, and extract with 300L of pure water at 5°C for 10 minutes;

[0034] (3) Stand still for 30 minutes to separate the liquid, mark the organic phase, recycle and pack into barrels; adjust the pH of the water phase to 7.0 with 36% acetic acid, add 400 L of ethyl acetate to extract for 20 minutes;

[0035] (4) Stand still for 30 minutes to separate the liquid, mark the organic phase, recycle and pack into barrels; add 400 L of ethyl acetate to the water phase to extract for 20 minutes, let stand for 30 minutes to separate the liquid, and recover the organic phase;

[0036] (5) Add 0.5kg of EDTA, 0.5kg of hydrosulfite, and 10kg of activated carbon to the water phase, and cool down and stir for 30 mi...

Embodiment 2

[0044] (1) Add 400L chloroform, 50kg MICA-active ester into a clean reaction tank, add 30kg AVNA, 136.4L pure water, 32.8L triethylamine after dissolving, keep the temperature at 15°C, and react for 4 hours;

[0045] (2) Add 680L of ethyl acetate after the reaction, and extract with 400L of pure water at 3°C for 20 minutes;

[0046](3) Stand still for 60 minutes to separate liquids, mark the organic phase, recycle and pack into barrels; adjust the pH of the water phase to 6.2 with 36% acetic acid, add 450 L of ethyl acetate to extract for 30 minutes;

[0047] (4) Stand still for 60 minutes to separate the liquid, mark the organic phase, recycle and pack into barrels; add 450 L of ethyl acetate to the water phase to extract for 30 minutes, let stand for 60 minutes to separate the liquid, and recover the organic phase;

[0048] (5) Add 1kg of EDTA, 1kg of hydrosulfite, and 12kg of activated carbon to the water phase, and cool down and stir for 60 minutes to decolorize;

[004...

Embodiment 3

[0056] (1) Add 500L of dichloromethane, 45kg of MICA-active ester into a clean reaction tank, add 28kg of AVNA, 127L of pure water, and 30L of triethylamine after dissolving, keep the temperature at 13°C, and react for 3 hours;

[0057] (2) Add 630L of ethyl acetate after the reaction, and extract with 370L of pure water at 4°C for 15 minutes;

[0058] (3) Stand still for 50 minutes to separate the liquid, mark the organic phase, recycle and pack into barrels; adjust the pH of the water phase to 8.5 with 36% acetic acid, add 430 L of ethyl acetate to extract for 25 minutes;

[0059] (4) Stand still for 50 minutes to separate the liquid, mark the organic phase, recycle and pack into barrels; add 430 L of ethyl acetate to the water phase to extract for 25 minutes, stand still for 50 minutes to separate the liquid, and recover the organic phase;

[0060] (5) Add 0.8kg of EDTA, 0.8kg of hydrosulfite, and 11kg of activated carbon to the water phase, and cool down and stir for 45 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com