Construction materials flammability test device

A technology for test devices and building materials, which is applied to measurement devices, analytical materials, instruments, etc., can solve the problems of inapplicable flammability tests, lack of test instruments, inability to test, etc., and achieves low cost, convenient production and safe operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

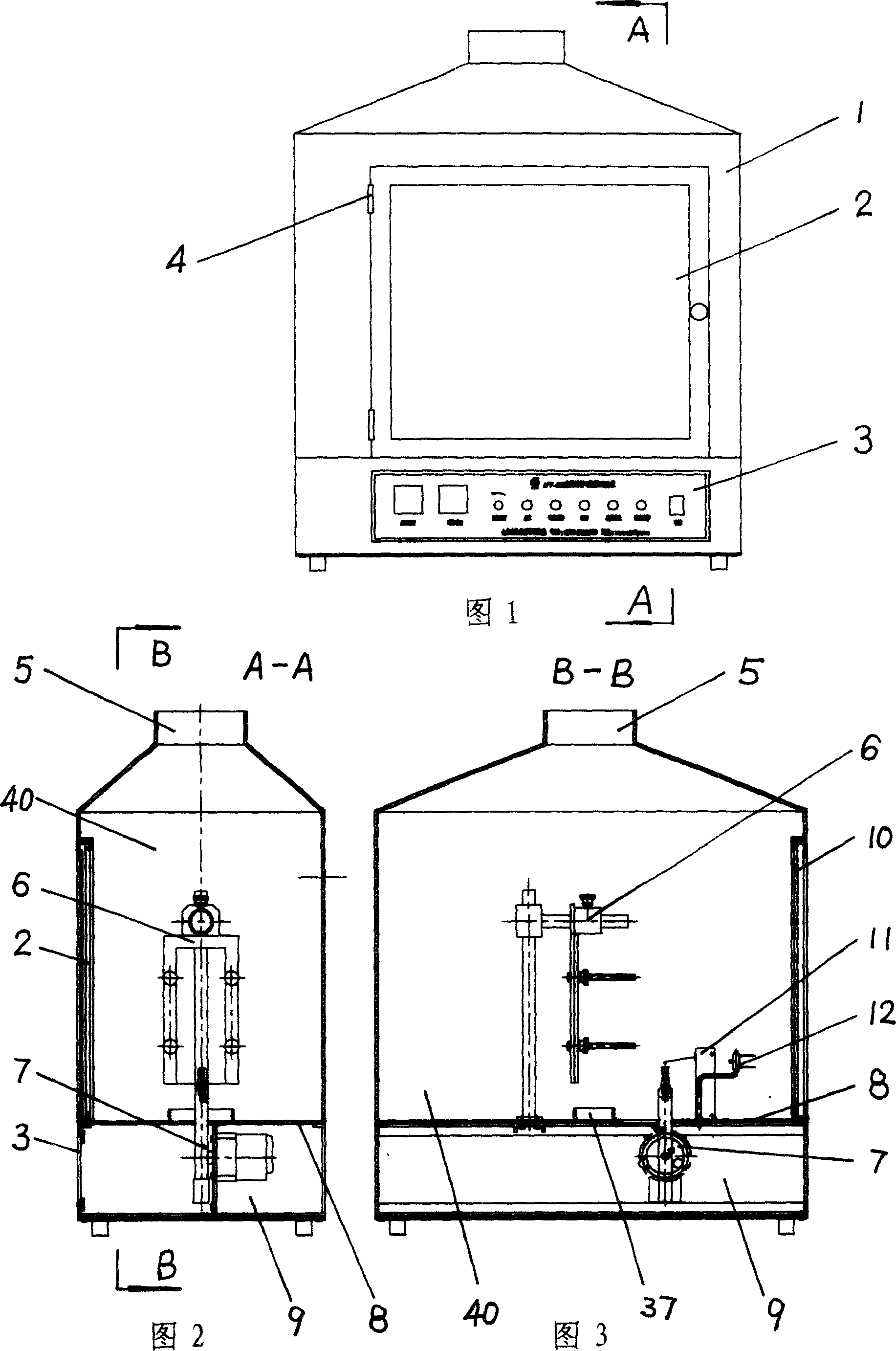

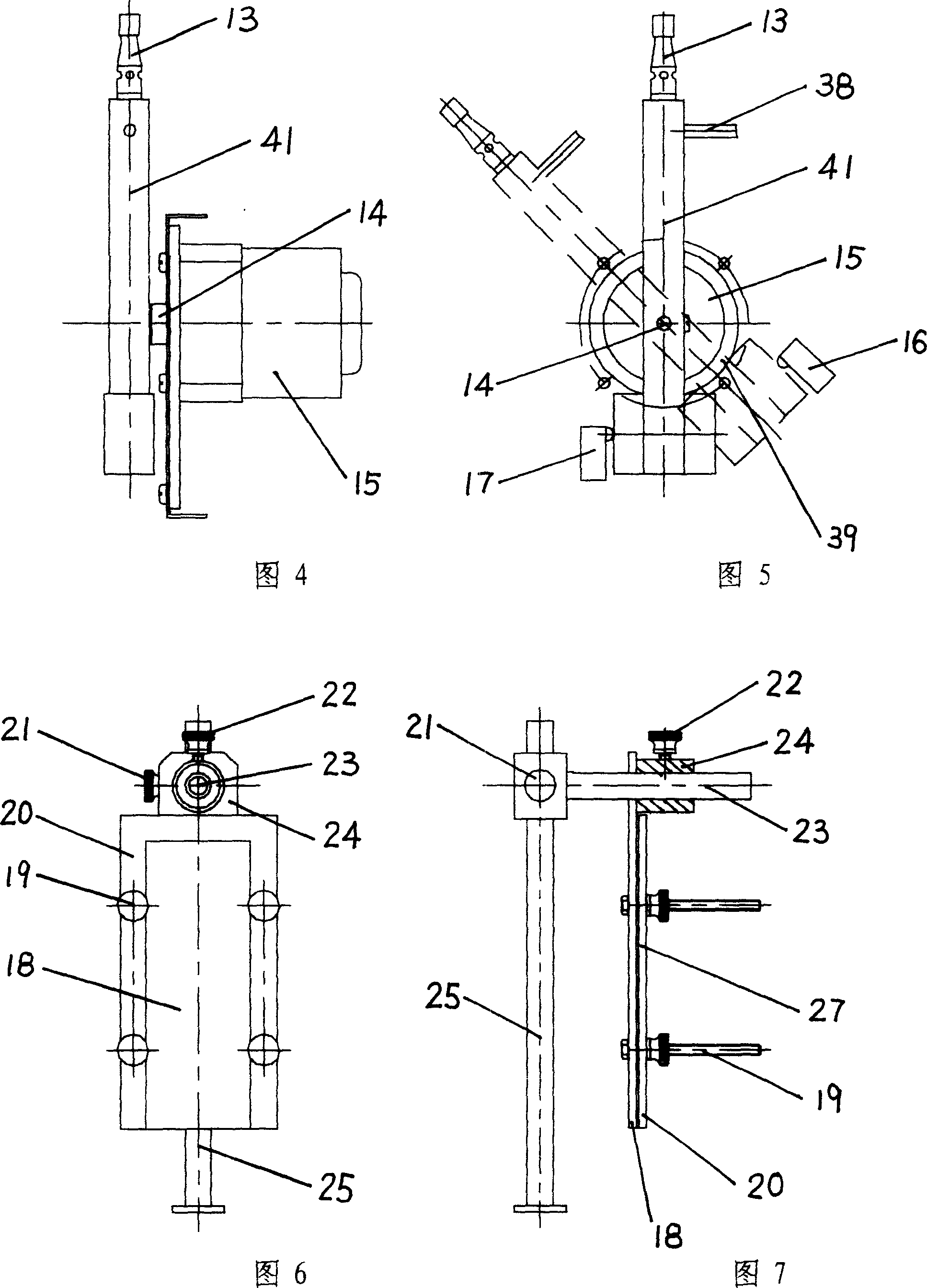

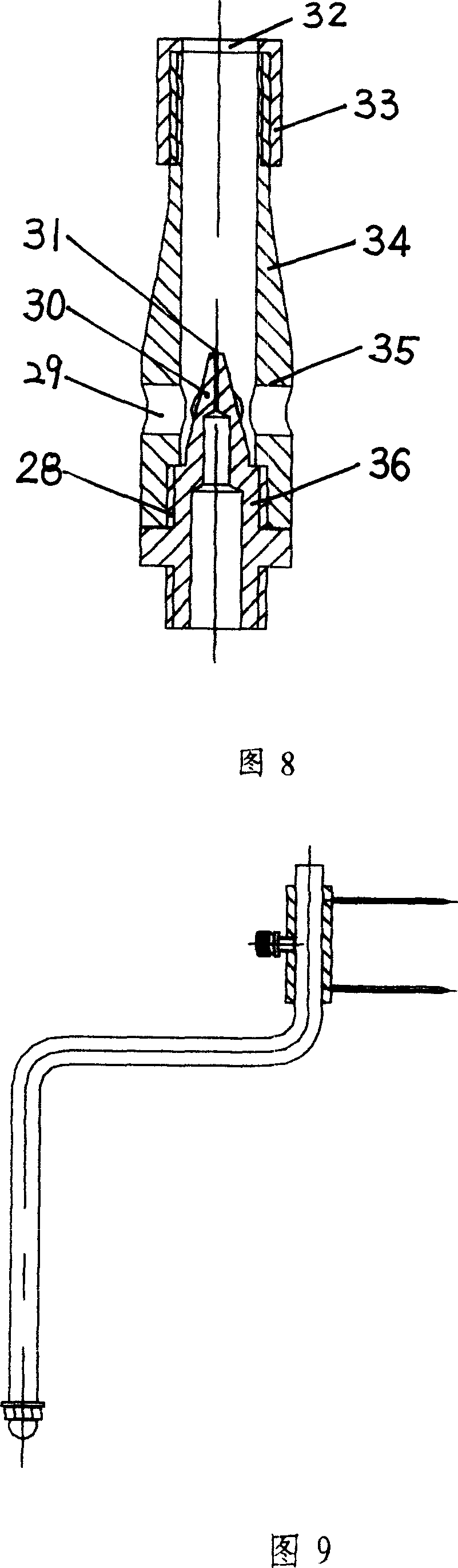

[0023] The embodiment of the present invention is a specific design scheme of a building material flammability test device, which is composed of a box body 1 with a box door 2, a sample clamping structure 6 installed in the box body 1, and a combustion structure 7. , the box door 2 is connected with the box body 1 through the box door connecting hinge 4, the box door 2 can be equipped with a transparent heat-resistant door plate to observe the combustion situation, and a side door 10 is also placed on the right side of the box body 1, and the combustion structure 7 is composed of 13 and the burner rotating structure 39 are assembled, the sample clamping structure 6 is assembled by the vertical rod structure 25, the horizontal rod structure 23 and the sample rack structure 27, and the burner 13 is composed of the air nozzle 36, the oxygen mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com