Oil and gas combustion special-shaped kitchen range

A special-shaped, gas-fired technology, used in household stoves/stoves, heating fuels, climate sustainability, etc., can solve the problems of large equipment volume, low energy utilization rate, and small food processing volume, and achieve small size and improve efficiency. The degree of utilization and the effect of large amount of food processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

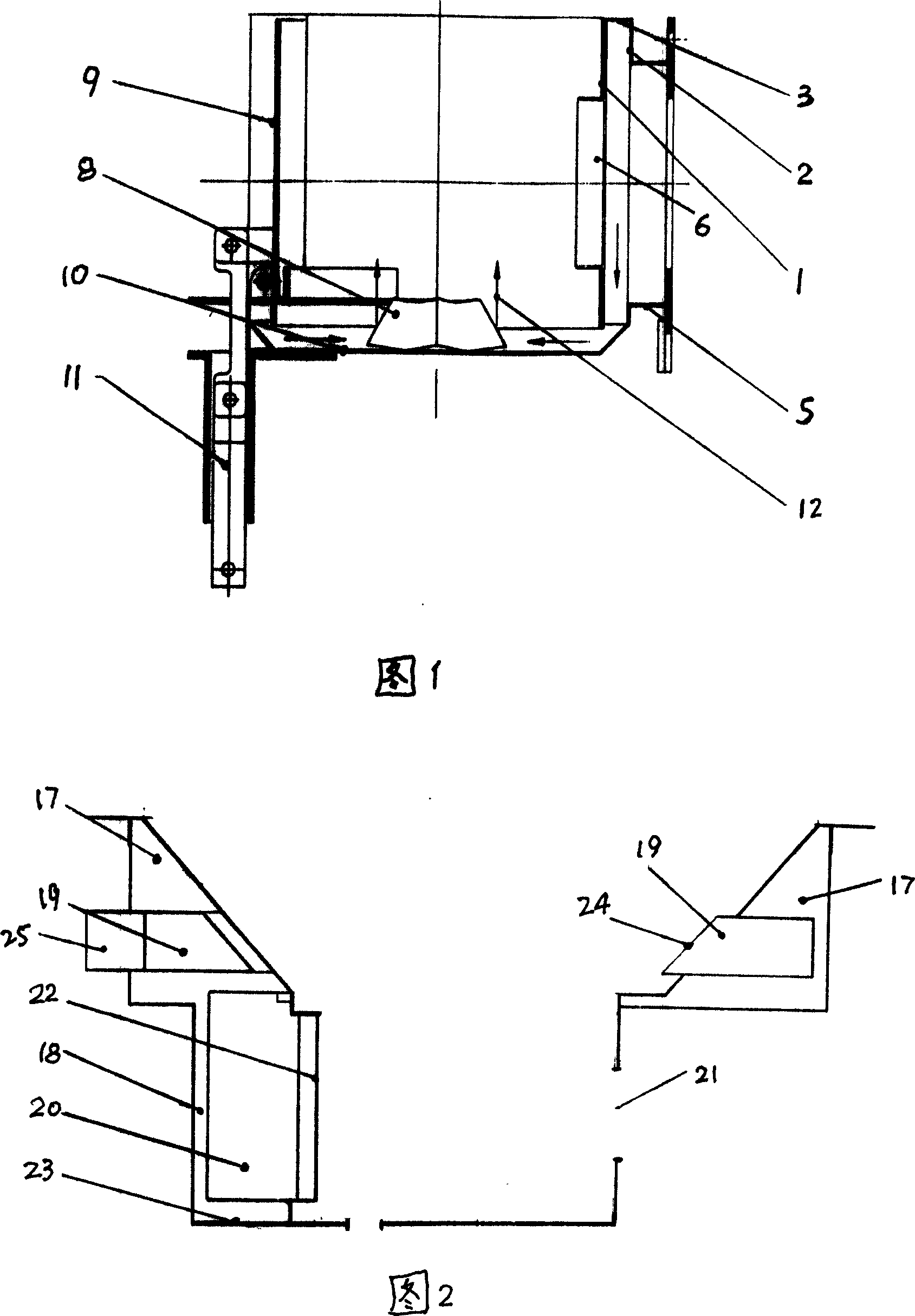

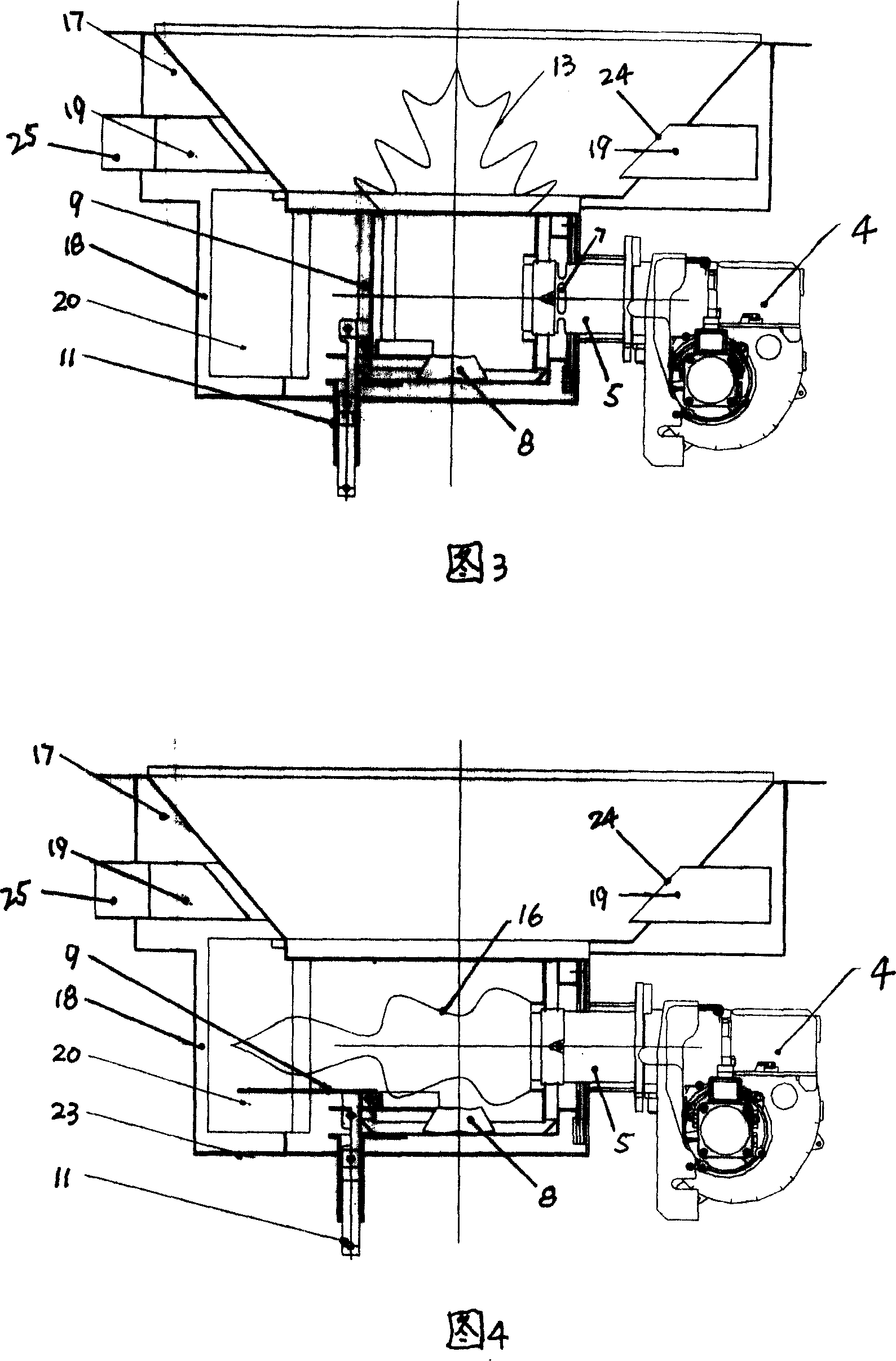

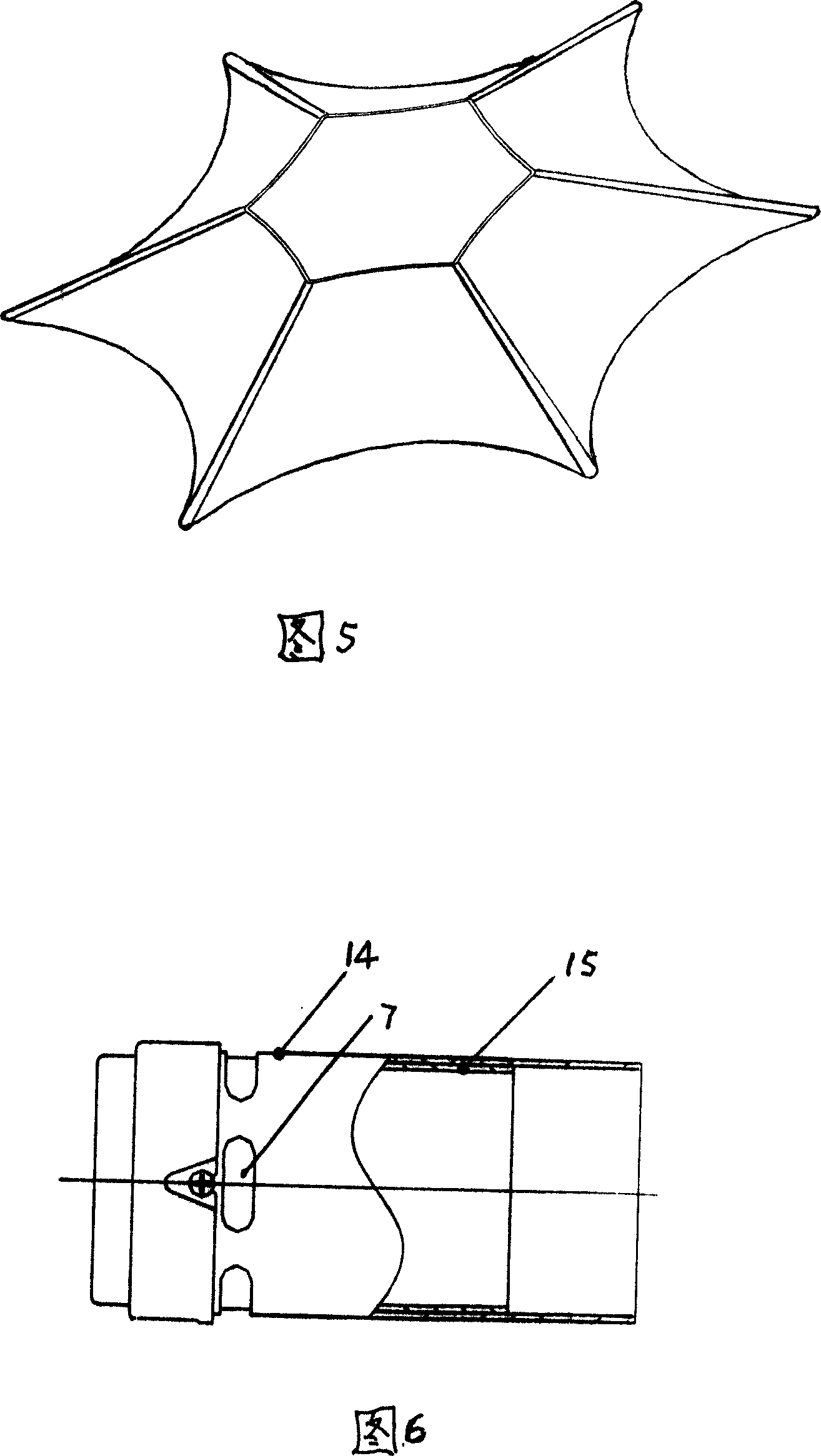

[0015] Embodiment: see Fig. 1~6. Part of the side wall of the furnace core with the upper opening is a sandwich hollow structure composed of an inner wall 1 and an outer shell 2 . The top of the interlayer hollow part is closed by the top plate 3 and the bottom is open. The interlayer hollow part is provided with a through hole 6 that can be docked with the outlet of the combustion tube 5 of the burner 4. When the combustion tube 5 is docked, the interlayer hollow part and the through hole 7 of the combustion tube (for the air outlet, see the following for the specific structure) described) connected. A guide 8 is fastened in the center of the bottom plate 10 of the furnace core, which can block the air flowing along the bottom plate and guide it to flow upward. The guide 8 is hollow and has six concave curved surfaces. A movable flap 9 that can be closed and opened is provided on the opposite side wall of the through hole 6. 11 is a linkage mechanism for manipulating the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com