Tank vehicle mounted breathing type safety valve

A safety valve and tanker technology, applied in safety valves, balance valves, valve devices, etc., can solve the problems of limited suction volume, poor stability and reliability, and achieve increased suction area, high reliability, and stable suction flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

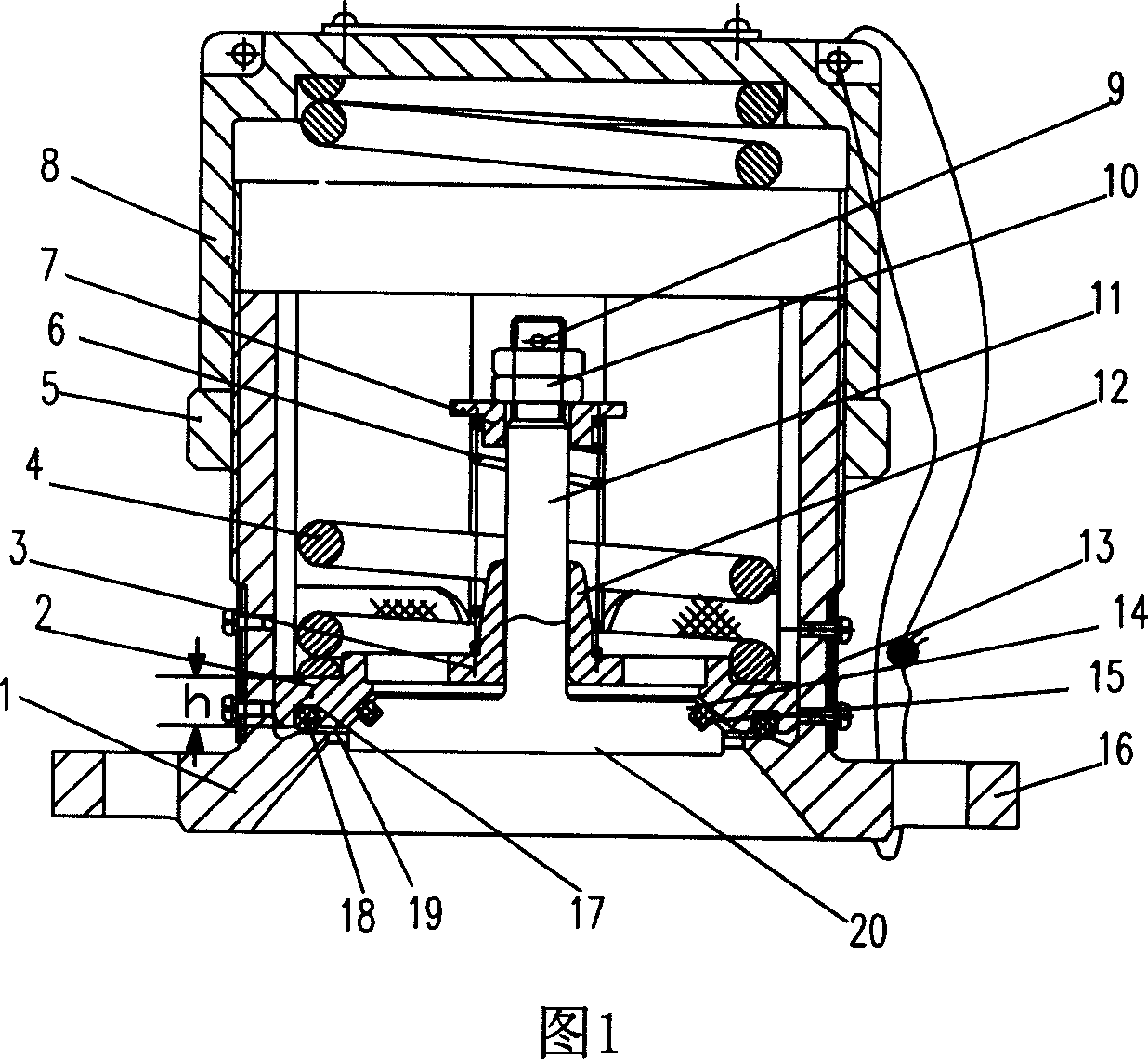

[0034] Referring to accompanying drawing 1, the upper end of barrel-shaped valve body 1 of the present invention is provided with bonnet 8, and bonnet 8 can be threadedly connected with valve body 1 by internal thread or external thread, and the junction of bonnet 8 and valve body 1 is provided with bonnet Lock nut 5 is advisable. When the quality of the medium is required to be high, a dust-proof net 13 can be provided at the bottom of the valve body 1 to prevent dust from accumulating, so as to ensure the reliability and tightness of the exhalation operation. The exhalation valve disc 2 is arranged in the valve body 1 and is in clearance fit with the valve body 1 . If the gap is small, the disc is prone to jamming; if the gap is large, it is easy to vibrate and the suction flow is limited. The gap between the exhalation valve disc 2 and the valve body 1 can be 0.08-0.25 mm. The gap between the exhaled disc 2 and the valve body 1 is preferably 0.1-0.2 mm. When the exhalati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com