Modified tempering method in sludge treatment process and application thereof

A sludge treatment and sludge technology, applied in dehydration/drying/thickened sludge treatment, sustainable waste treatment, solid waste management, etc., can solve problems such as drying cracks and surface cracking of bricks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

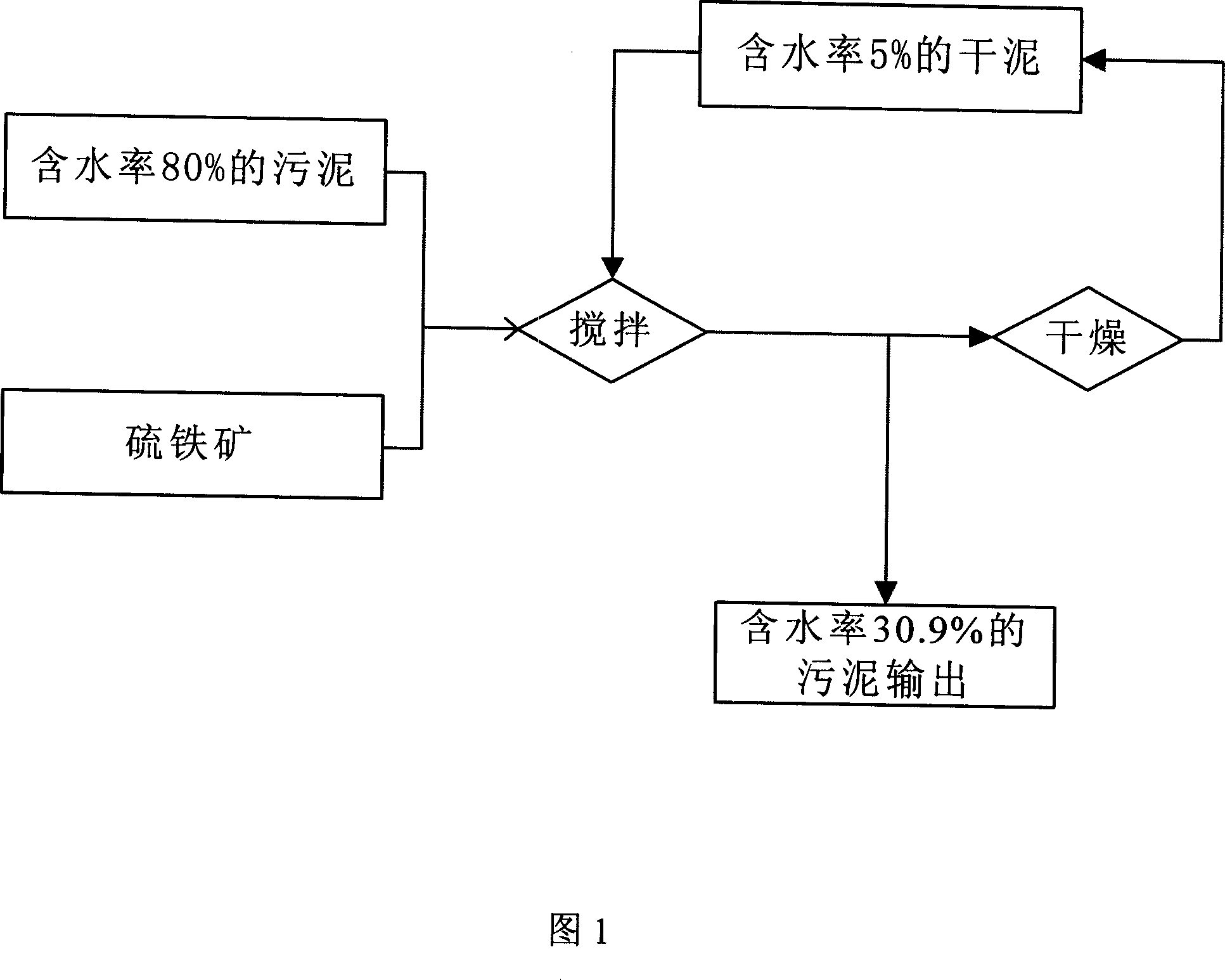

[0014] As shown in Figure 1, the sludge with a water content of 80% is mixed with pyrite, wherein the mixed pyrite accounts for 10% of the total weight, and then the mixture is sent into the mixer, and the mixer adopts a double-shaft roller type mixer, add dry sludge with a moisture content of 5% while stirring, and temper the sludge to a sludge with a moisture content of 30.9%. After obtaining 30.9% sludge, part of the sludge is dried to obtain a moisture content of 5%. % of the sludge is returned to the stirring and conditioning stage. The remaining 30.9% of the sludge is discharged for further treatment, such as brick making and other comprehensive utilization processes.

Embodiment 2

[0016] Add pyrite into sludge with a moisture content of 75%, wherein the mixed pyrite accounts for 40% of the total weight, and add dry mud with a moisture content of 7% while stirring, and temper the sludge to a moisture content of It is 35.0% sludge. After obtaining 35.0% sludge, part of the sludge is dried to obtain sludge with a moisture content of 7%, and then returns to the stirring and tempering stage. The remaining 35.0% of the sludge is discharged for further treatment, such as brick making and other comprehensive utilization processes.

Embodiment 3

[0018] Mix the fly ash into the sludge with a water content of 70%, wherein the mixed fly ash accounts for 2% of the total weight, and then send the mixture into the mixer. The mixer adopts a double-shaft counter-rolling mixer. Add dry sludge with a moisture content of 8%, and temper the sludge to a sludge with a moisture content of 32.3%. After obtaining 32.3% sludge, part of the sludge is dried to obtain dry sludge with a moisture content of 8%, and then return Stirring and tempering phase. The remaining 32.3% of the sludge is discharged for further treatment, such as brick making and other comprehensive utilization processes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com