Six-rod whole hinge single-row drive type double pendulum angle milling head

A double swing angle milling head, driven technology, applied in the field of machine tools, can solve the problems of high stiffness, high load, low bearing capacity, etc., and achieve the effect of ensuring the range of motion, modular design, and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

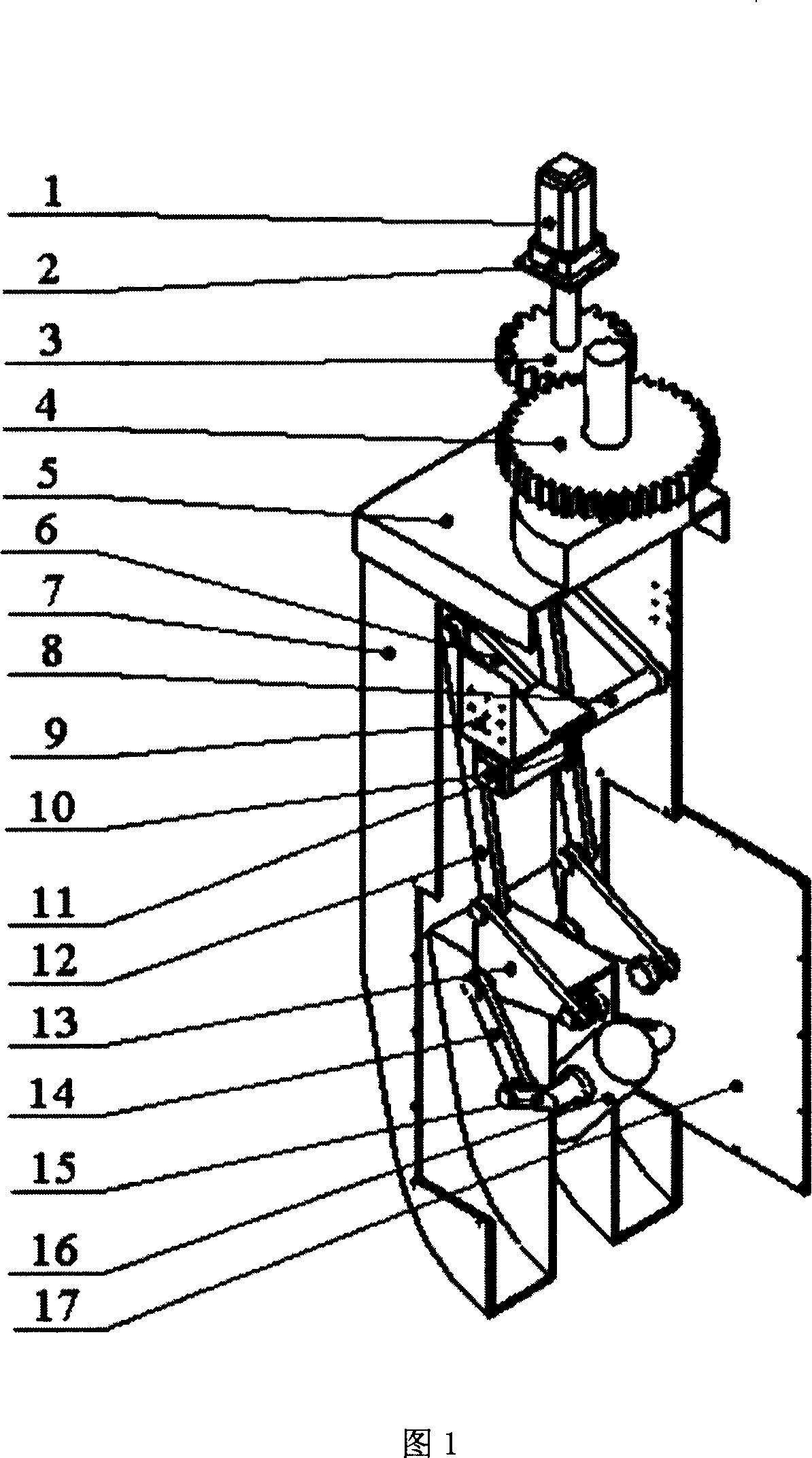

[0012] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0013] As shown in Figure 1, this embodiment includes: a first controllable motor 1, a first coupling 2, a first cylindrical gear 3, a second cylindrical gear 4, a milling head cover plate 5, and a first pair of connecting rods 6. Milling head cover 7, transmission shaft 8, bracket 9, second controllable motor 10, second coupling 11, first pair of connecting rods 12, second pair of connecting rods 13, second pair of connecting rods 14, first Three pairs of connecting frame rods 15, milling head electric spindle 16 and a pair of milling head cover side cover plates 17.

[0014] Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com