Clock pendulum driving device with improved structure

A driving device and a pendulum technology, applied to the driving mechanism of clocks, mechanically driven clocks, clocks and watches, etc., can solve the problems of inconvenient maintenance and repair, cumbersome use and operation, and huge clockwork mechanism, and achieve easy maintenance, simplified transmission mechanism, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

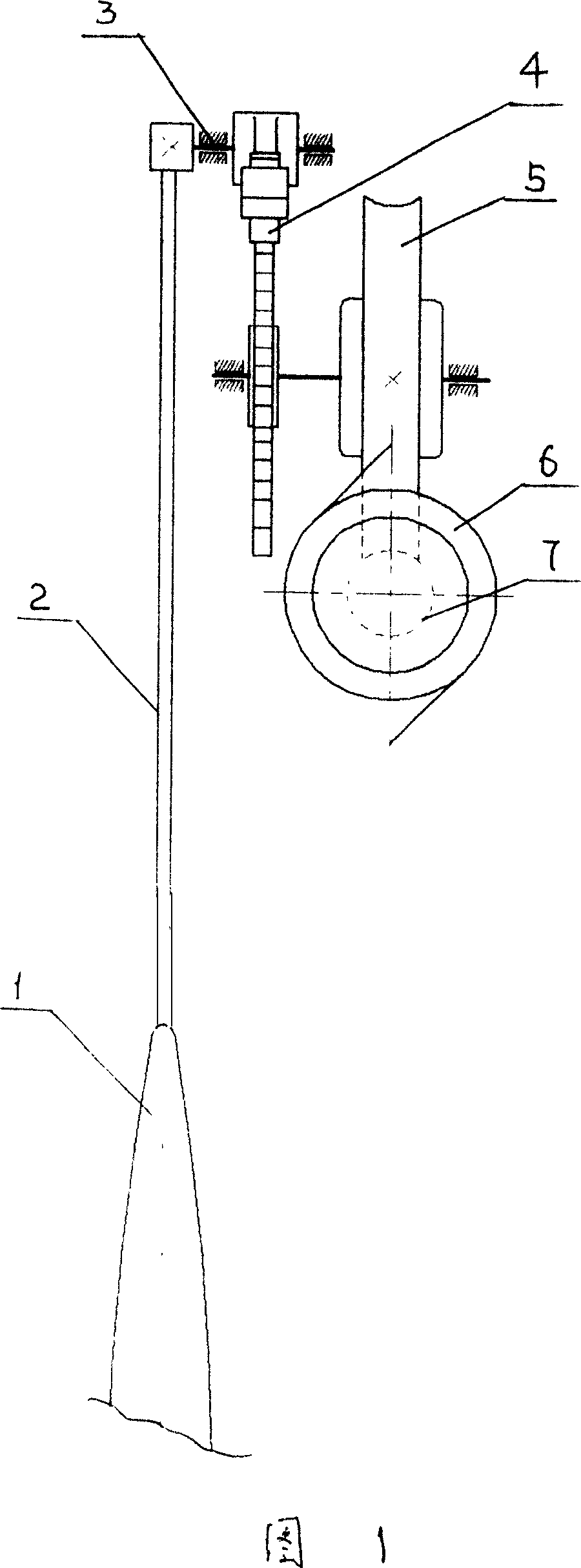

[0014] As shown in FIG. 1 , this embodiment includes a pendulum 1 , a pendulum mechanism 2 for driving the pendulum 1 to swing, and an escapement mechanism 4 for driving the pendulum mechanism 2 to work. Also be provided with motor 6, its output shaft is connected with worm screw 7, and the worm wheel 5 that is connected with this worm screw is connected with the escape wheel of escapement mechanism.

[0015] The upper end of the swing rod mechanism 2 is fixedly connected with the outer end of the swing rod drive shaft 3 , and the inner end of the swing rod drive shaft 3 is connected with the pallet fork of the escapement mechanism 4 .

[0016] Wherein the worm wheel 5 is coaxially connected with the escape wheel of the escapement mechanism 4 .

Embodiment 2

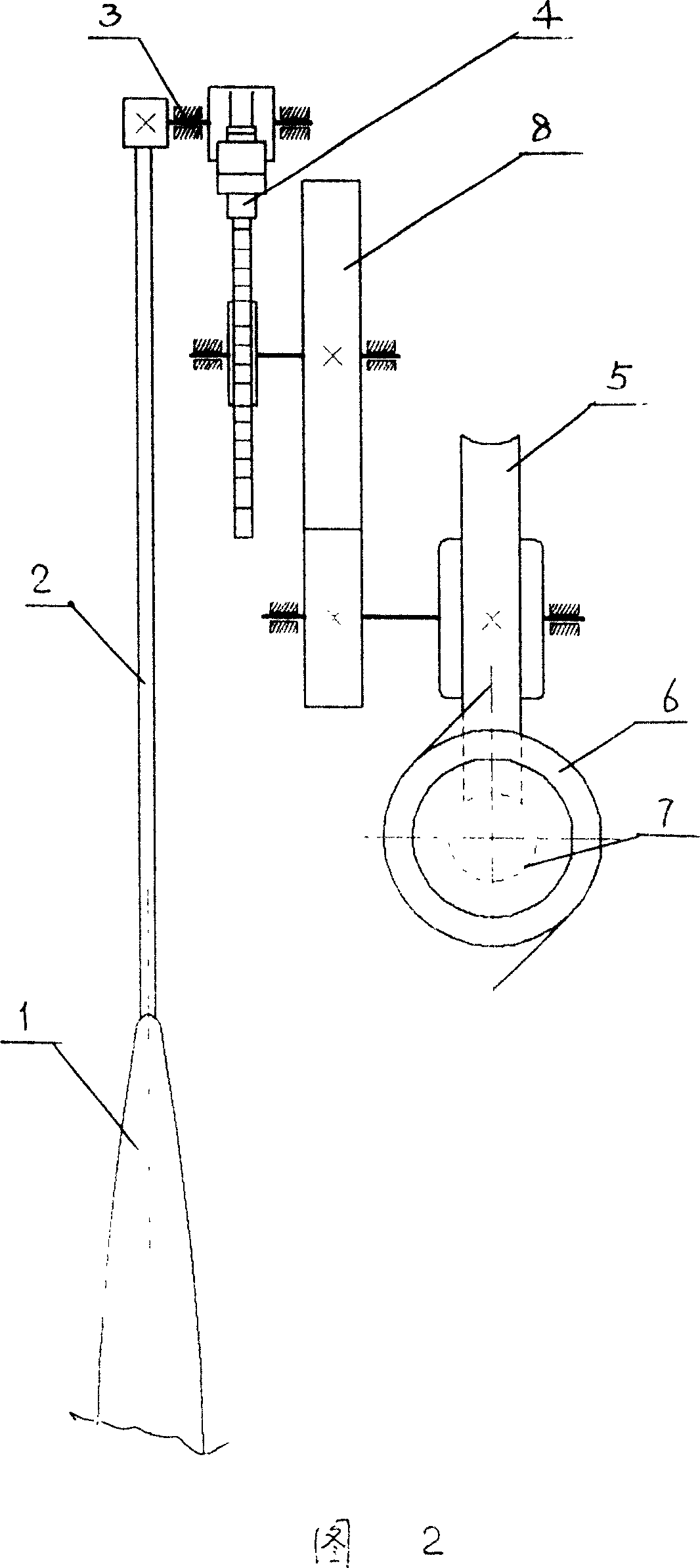

[0018] As shown in FIG. 2 , on the basis of the first embodiment, a gear transmission mechanism 8 is added, the worm gear 5 is coaxially connected with the driving gear therein, and the driven gear is coaxially connected with the escape wheel of the escapement mechanism 4 .

Embodiment 3

[0020] The motor 6, the worm 7, the worm wheel 5 and the escapement mechanism 4 are fixed in the casing to form an independent pendulum drive motor, which is directly connected with the pendulum drive shaft 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com