Aeration device for polluted water purification processing and water scene, and its production method and usage method

A technology of sewage purification and aeration device, applied in water/sludge/sewage treatment, water aeration, chemical instruments and methods, etc. The design concept is scientific, the scope of use is expanded, and the debugging is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

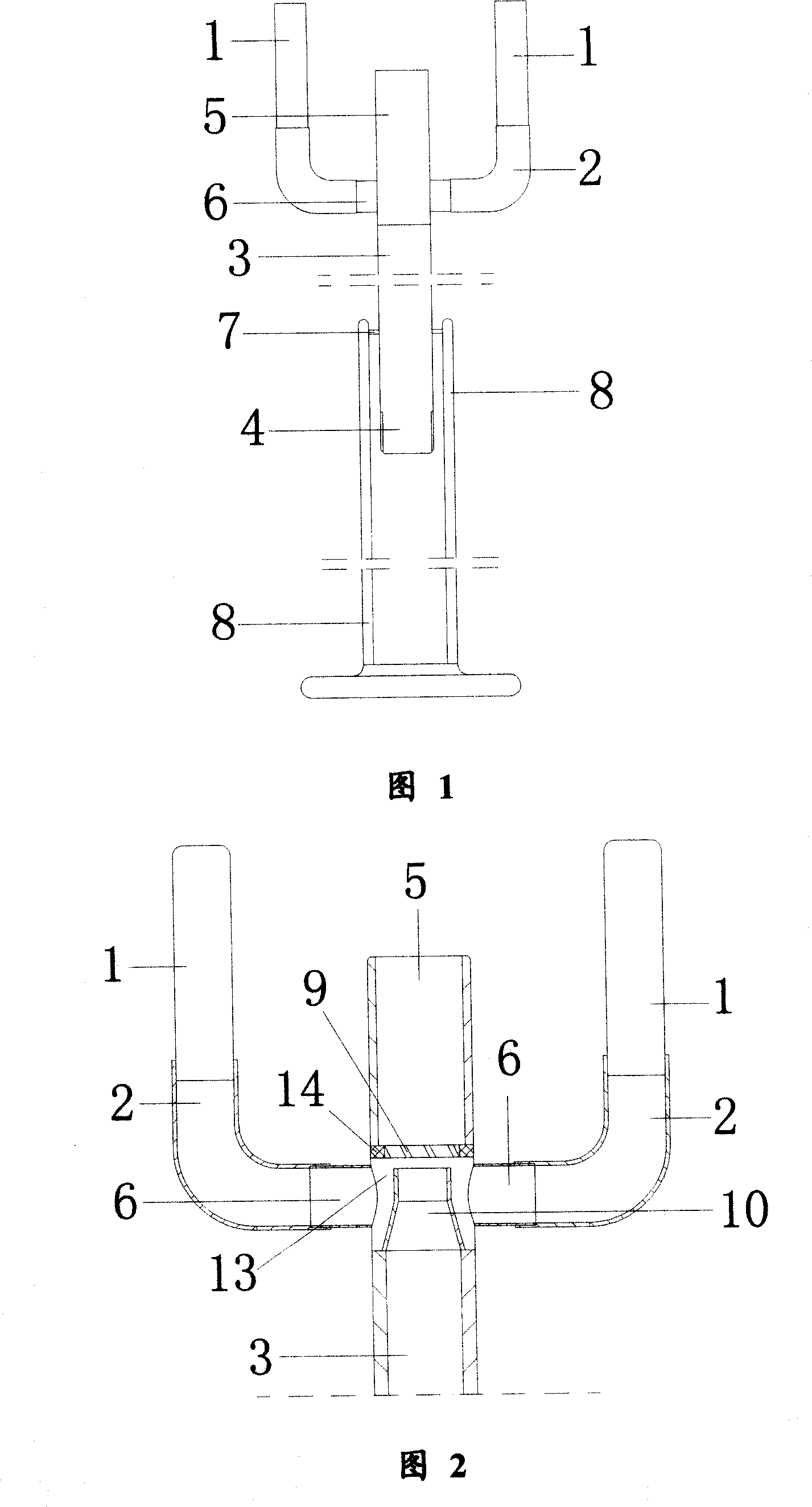

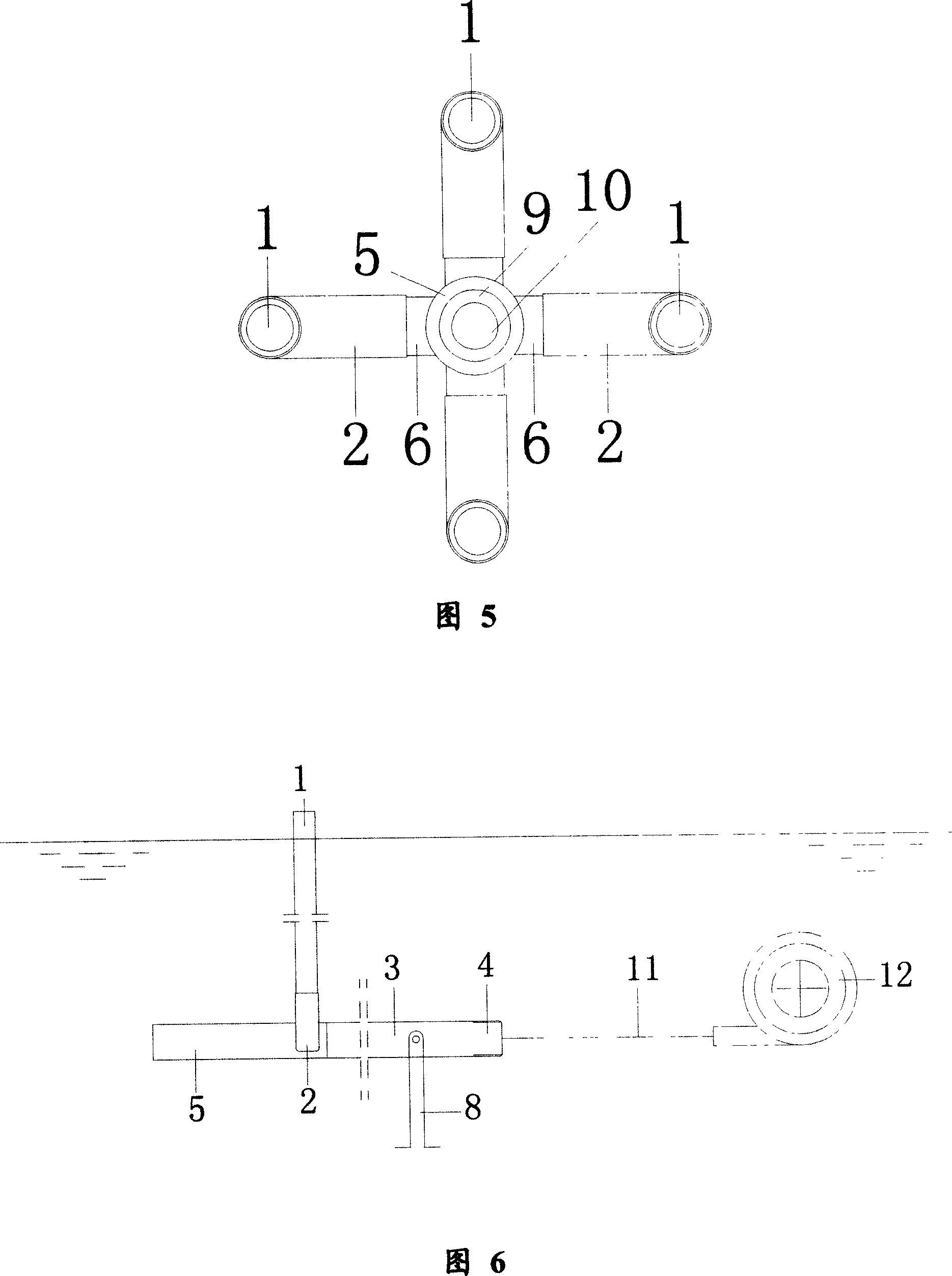

[0048] The water inlet pipe (3) is cylindrical, hollow in the pipe, and the top end of one end of the water inlet pipe (3) is connected smoothly with the other end of the air-water mixing nozzle (5). The pipes (5) are connected, the other end of the water inlet pipe (3) is the water inlet pipe port (4), the water inlet pipe port (4) is connected with the pipe (11), and the water body is delivered to the water inlet pipe (3) through (11) .

[0049] Two air supply pipes (6) are equidistantly arranged on the outside of one end of the water inlet pipe (3), and one end of the air supply pipe (6) is connected with the outside of one end of the water inlet pipe (3), and the air supply pipe (6) and the water inlet pipe (3) are connected with each other, and the air supply pipe (6) delivers air evenly to the water inlet pipe (3), as shown in Fig. 1 , Fig. 2 and Fig. 3 .

Embodiment 2

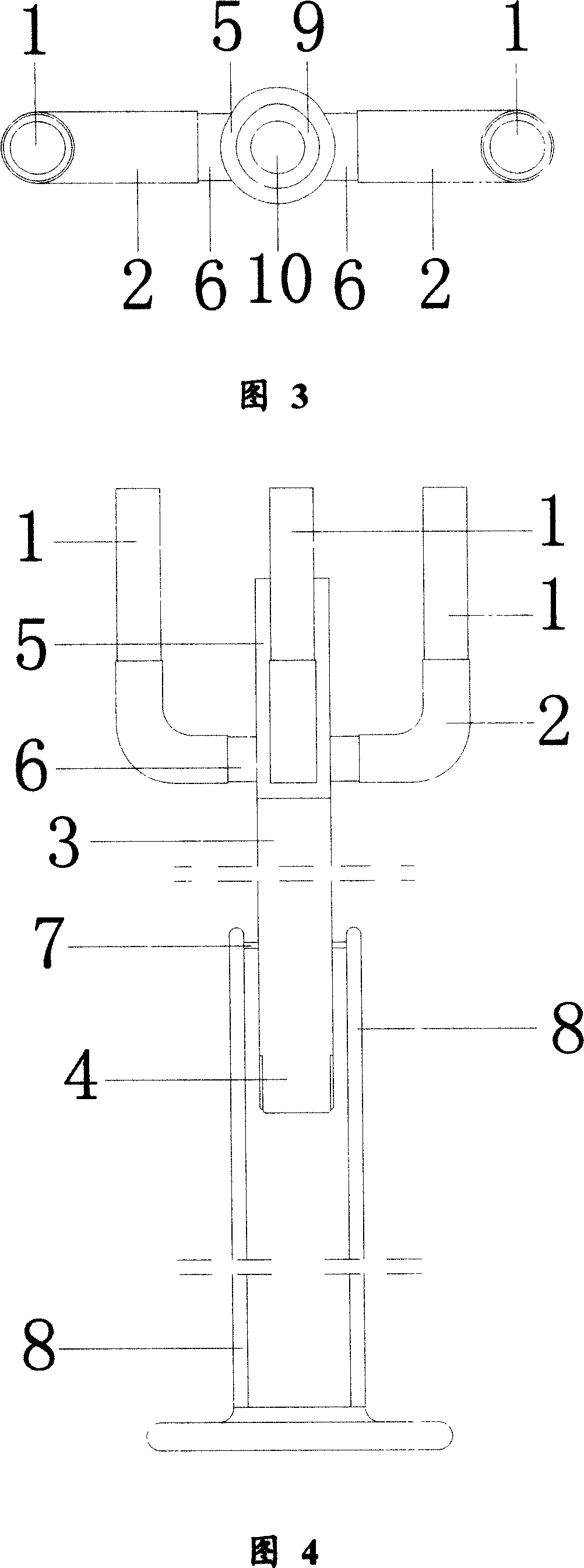

[0051] The water inlet pipe (3) is cylindrical, hollow in the pipe, and the top end of one end of the water inlet pipe (3) is connected smoothly with the other end of the air-water mixing nozzle (5). The pipes (5) are connected, the other end of the water inlet pipe (3) is the water inlet pipe port (4), the water inlet pipe port (4) is connected with the pipe (11), and the water body is delivered to the water inlet pipe (3) through (11) .

[0052] Four air supply pipes (6) are equidistantly arranged outside one end of the water inlet pipe (3), and one end of the air supply pipe (6) is connected with the outside of one end of the water inlet pipe (3), and the air supply pipe (6) is connected to the water inlet pipe. (3) are connected with each other, and the air supply pipe (6) evenly delivers air to the water inlet pipe (3), as shown in Fig. 2, Fig. 4 and Fig. 5 .

Embodiment 3

[0054] The other end of the air supply pipe (6) is movably connected with the other end of the swivel elbow (2), one end of the air supply pipe (6) is fixedly connected with the other end of the air induction pipe (1), and the swivel elbow (2) ) drives the air-inducing pipe (1) to rotate along the air-delivery pipe (6), and air is transported into the water inlet pipe (3) by the air-inducing pipe (1), the swivel elbow (2) and the air-delivery pipe (6).

[0055] A conical nozzle (10) is arranged in the pipe at one end of the water inlet pipe (3), and the inner wall of the nozzle (10) is smoothly connected with the inner wall of the water inlet pipe (3). speeds up the flow of water.

[0056] A negative pressure guide pressure ring (9) is arranged in the top end of one end of the water inlet pipe (3), and the negative pressure guide pressure ring (9) corresponds to the spray nozzle (10), and the negative pressure guide pressure ring (9) is Hollow cylindrical, the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com