Device for loading a vessel with solid particles and method using said device

A solid particle, cavity technology, applied in loading/unloading, chemical instruments and methods, transportation and packaging, etc., can solve the problems of excessive volume, difficult installation and disassembly, hard tube material, etc., to improve operational safety. , the effect of reducing the risk of tearing or decoupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

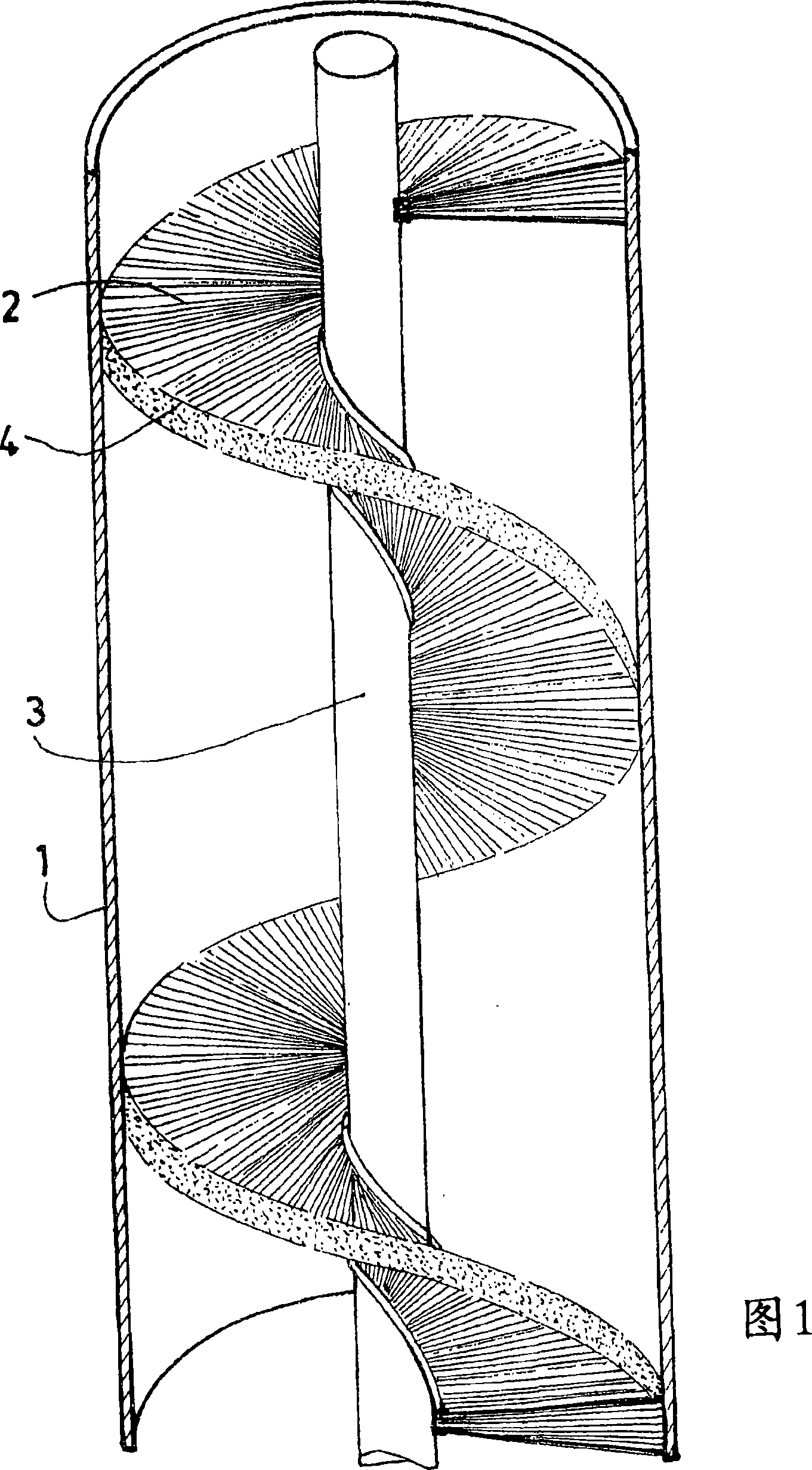

[0048] [48] FIG. 1 shows a section of a device according to the invention with a helical ramp 2 fixed on and coiled around a central axis 3, so that The central axis is here a solid rod. The spiral chute can be glued or welded to the center post through its bottom. The helical structure is surrounded by a flexible tube 1 . The diameter of the flexible tube is such that the distance between the outer edge 4 of the helical chute and the tube is smaller than the size of the particles to be loaded. The outer edge 4 of the chute 2 may be in frictional contact with the inner surface of the flexible tube.

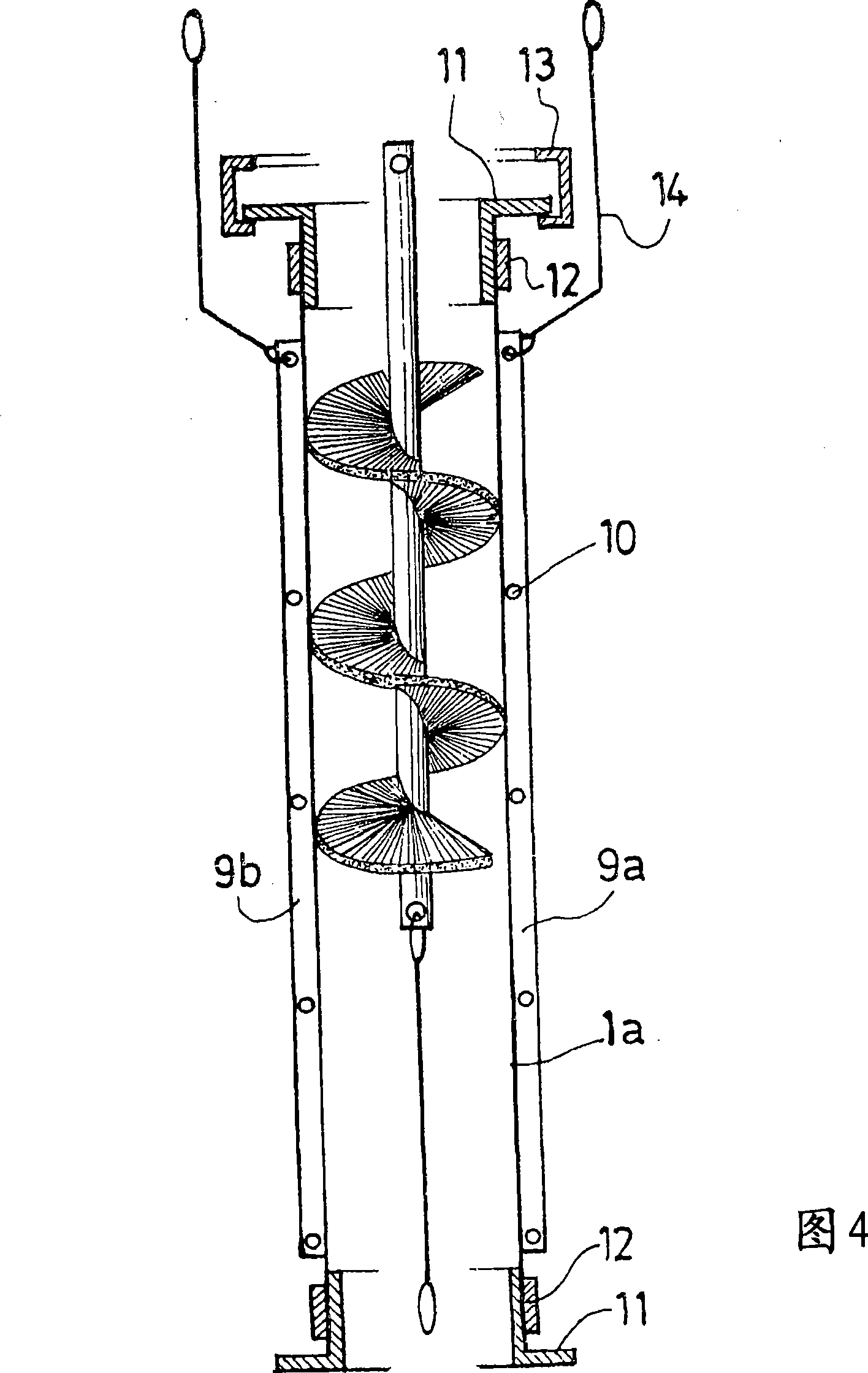

[0049] [49] FIG. 2 schematically shows the connection between two shaft elements 6 which each support a helical ramp 2 and are separated by an intermediate element 5 . The intermediate element 5 is connected to the shaft element 6 by means of a hinge 8, for example a ring-hook system, which facilitates and speeds up the installation and / or removal of the device. In the area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com