Antidazzle film and its production method, method for producing metal mould used therefore, and display device

A technology of metal molds and anti-glare films, which can be used in optics, instruments, optical components, etc., and can solve problems such as insufficient durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

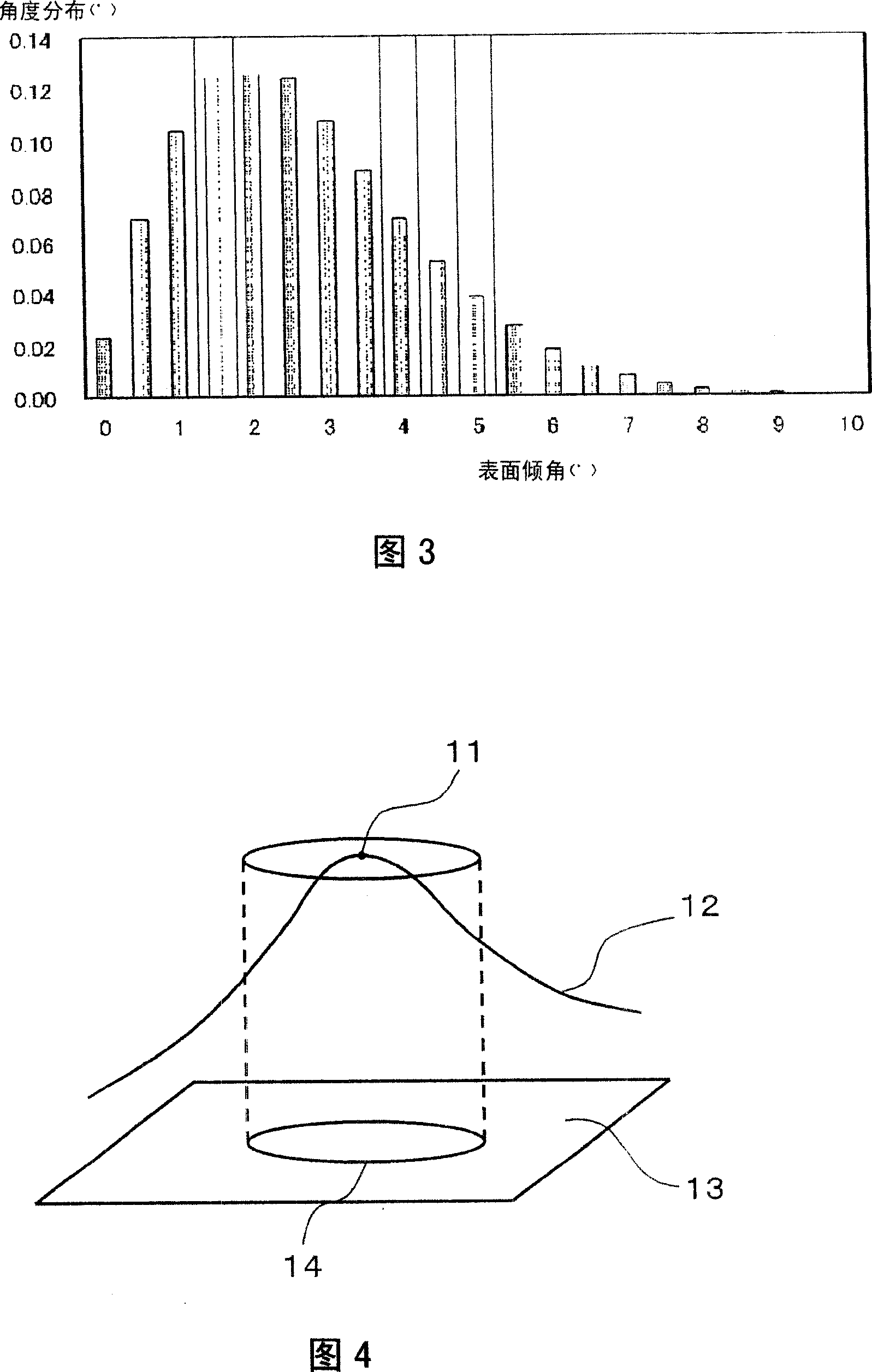

[0119] The surface of an aluminum coil (A5056 based on JIS) having a diameter of 200 mm subjected to copper ballard plating was prepared. Copper Ballard plating consists of copper plating / thin silver plating / surface copper plating, and the thickness of the entire plating is about 200μm. The surface of the copper electroplating is mirror-polished. In addition, when the injection pressure is 0.1MPa (gauge pressure, the same below), the injection pressure is 8g / cm 2 The amount of beads used (per 1cm 2 The amount used on the surface of the coil, the same below), by using a blasting device (manufactured by FUJI MANUFACTURING CO., LTD.), zirconium beads "TZ-SX-17" (trade name, average particle diameter) manufactured by Tosoh Corporation 20 μm) onto the polished surface to form concave-convex portions on the surface. Chromium plating was performed on the copper-plated aluminum coil having the thus-obtained concave-convex portions, and thus a metal mold was manufactured. At this ti...

Embodiment 2 and 3 and comparative example 1 and 2

[0129] In the same manner as in Example 1, a metal mold having concave-convex portions on the surface was prepared except that the conditions for producing the metal mold were changed as shown in Table 1. In the same manner as in Example 1, a corresponding metal mold was used to manufacture a transparent antiglare film having concave-convex portions on the surface and consisting of a laminated product of a cured resin and a TAC film . The surface shape, optical characteristics, and antiglare performance of the antiglare film thus obtained are shown in Table 1 together with the conditions for producing the metal mold. In Table 1, (A) illustrates the conditions for producing the metal mold and the surface shape of the antiglare film, and (B) illustrates the optical characteristics and antiglare performance of the antiglare film. In the table, ">99.5%" in the column of inclination angle "≤6°" means that the ratio of planes with an inclination angle equal to or less than 6 degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com