Superhydrophobic anti-glare rearview mirror

A rearview mirror and super-hydrophobic technology, which can be used in optical observation devices, layered products, chemical instruments and methods, etc., and can solve problems such as complex process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

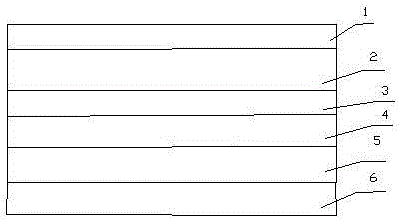

[0025] A superhydrophobic anti-glare rearview mirror, which consists of: glass 2, the front surface of the glass is closely attached to a superhydrophobic layer 2, the rear surface of the glass is closely attached to an antireflection film 3, and the antireflection film 3 is closely attached to the front surface of the glass. The metal nickel film 6 is closely attached to the back of the transparent film.

Embodiment 2

[0027] According to the superhydrophobic anti-glare rearview mirror described in Example 1, the glass is ordinary float glass, and the thickness of the glass is between 0.5 mm and 3 mm.

Embodiment 3

[0029] According to the superhydrophobic anti-glare rearview mirror described in Example 1, the superhydrophobic layer is aluminum-doped zinc oxide, and the thickness of the superhydrophobic layer is 100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap