Incineration equipment system of rotary kiln for hazardous waste garbage

A hazardous waste and rotary kiln technology, which is applied in the field of rotary kiln incineration equipment systems, can solve problems such as troublesome cleaning work, affecting the normal flow of flue gas, and blockage of smoke and dust, so as to prolong the working life, reduce the probability of recombination, and prevent recombination. generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

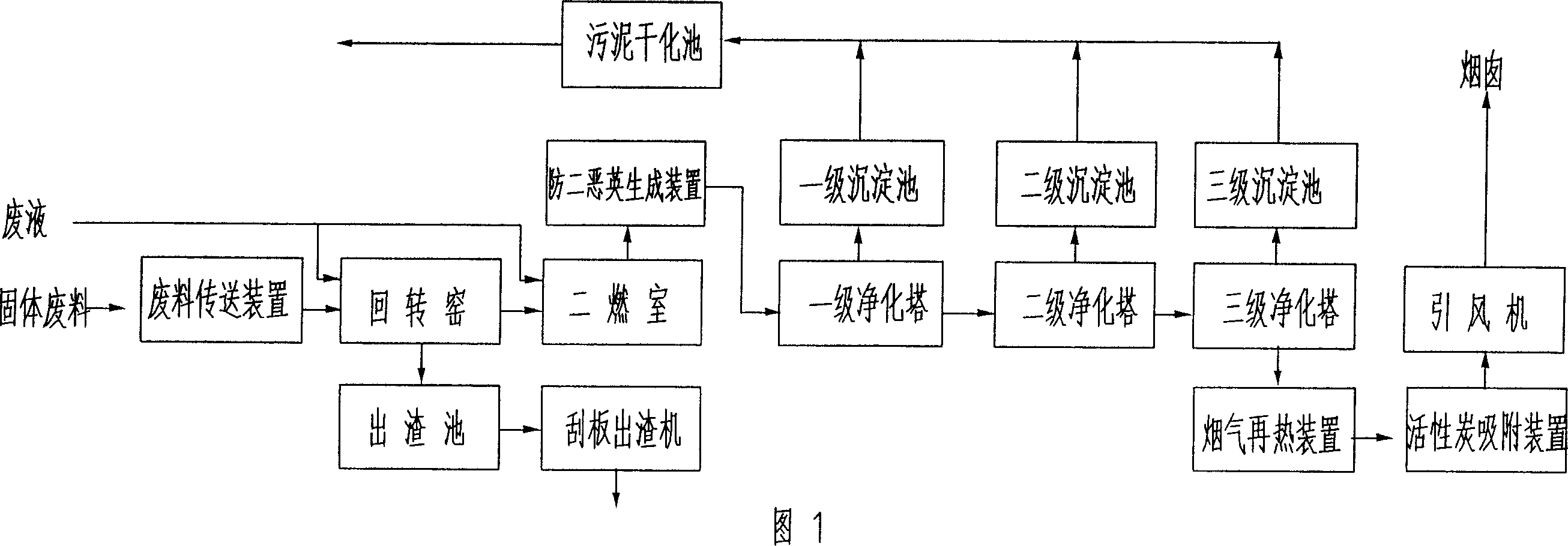

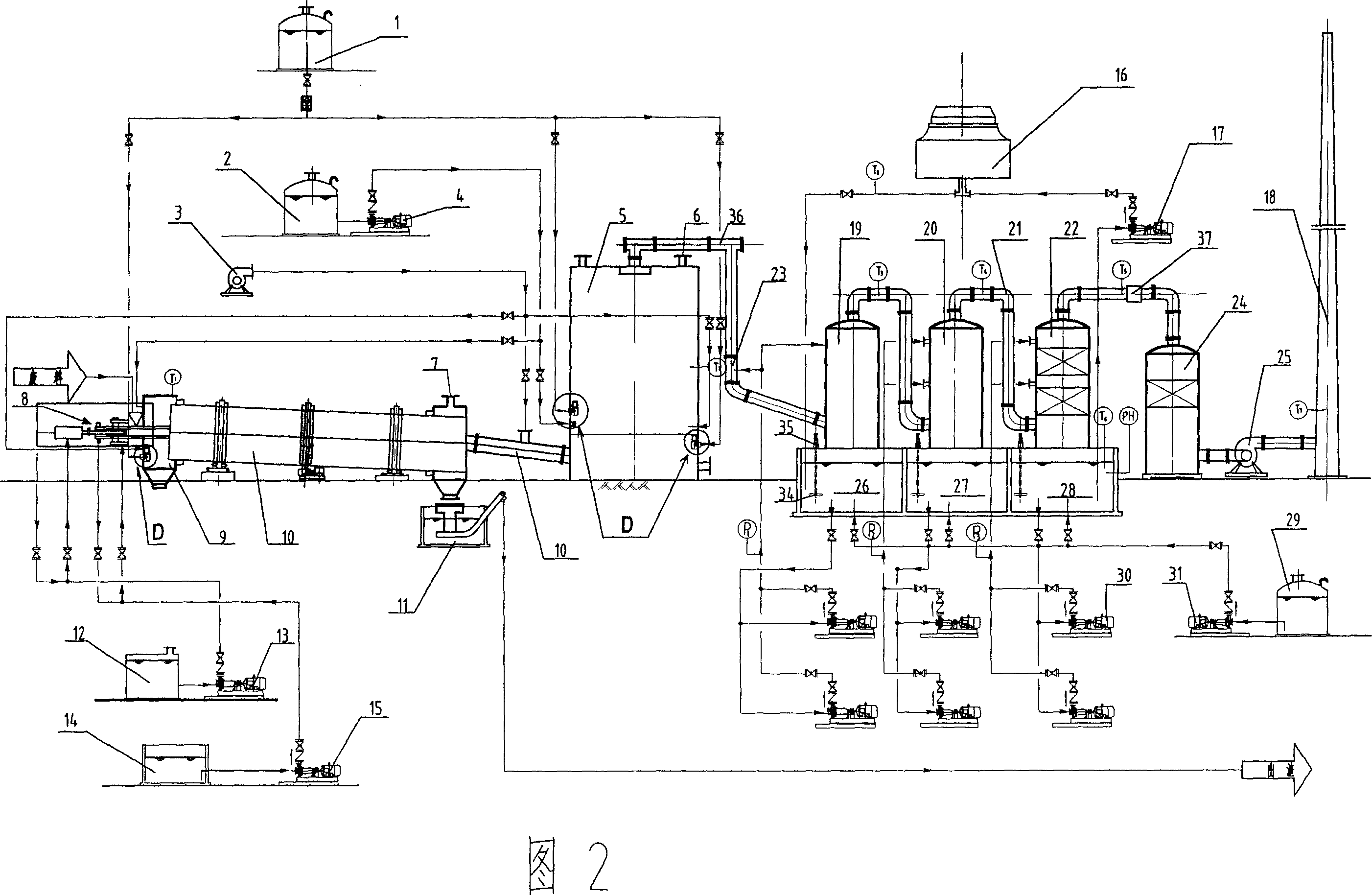

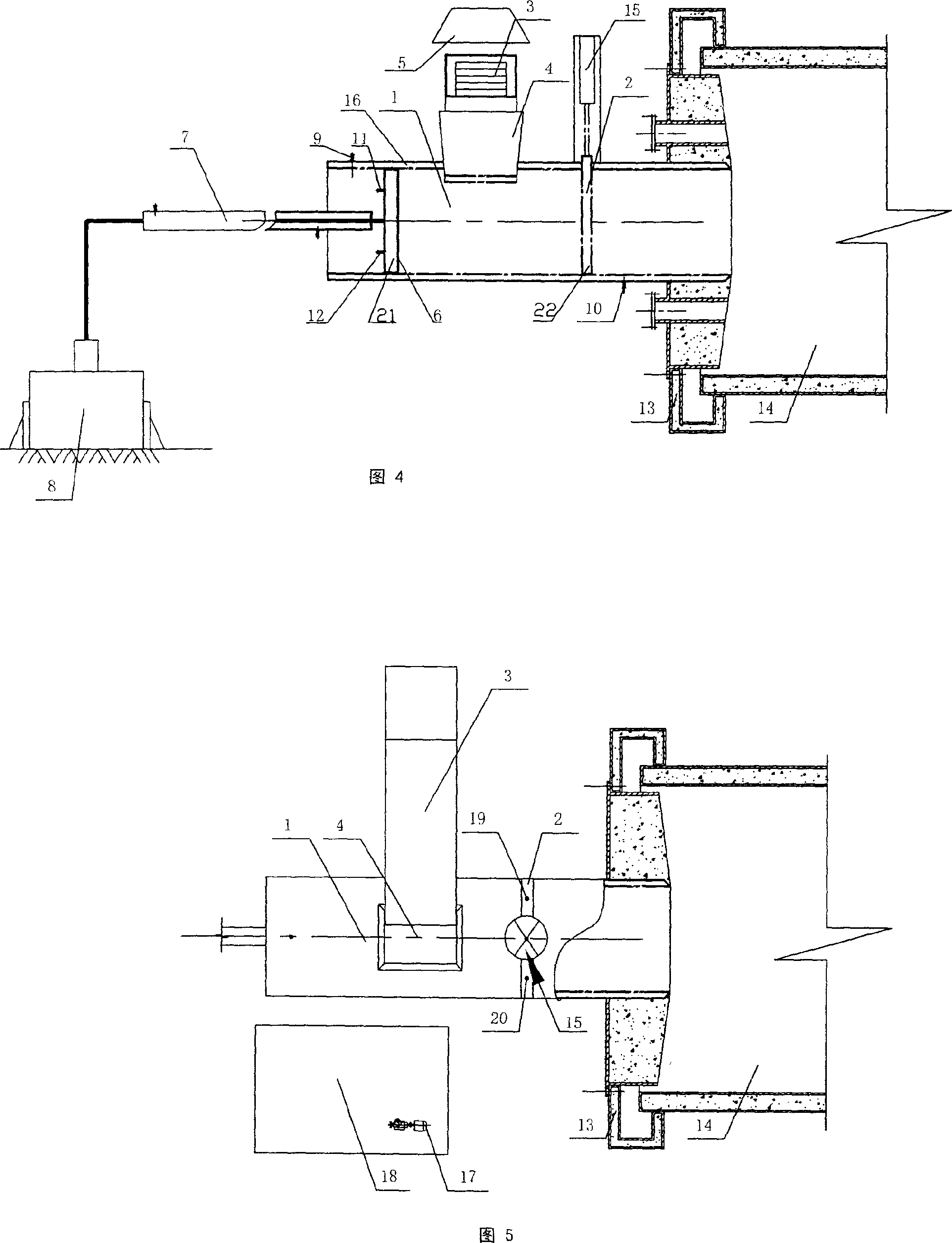

[0027] Combined with Fig. 1, Fig. 2 and Fig. 3, the rotary kiln incineration equipment system for waste treatment: the solid waste conveying device sends the waste into the rotary kiln 10 through the feeding device 8 of the rotary kiln head 9. The kiln head 9 of the rotary kiln is provided with a liquid spray head 33 and an oil spray head 32 extending into the kiln, and the hydraulic oil is provided by the oil tank 12 through the oil pump 13 circulation; each liquid spray head is connected with the waste liquid tank 2; the kiln of the rotary kiln The flue gas outlet of head 9 sends the flue gas that primary combustion produces into the bottom of secondary combustion chamber 5 through pipeline 36, and an explosion-proof door 7 is provided on the top. The ash generated by the primary combustion falls into the slag discharge tank and is transported out by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com