Method for reinforcing space nodes of beam column built from concrete

A space node and concrete technology, which is applied in construction, building maintenance, building construction, etc., can solve problems such as difficulty in ensuring concrete compactness, difficulty in pouring concrete, troublesome construction, etc., and achieves cheap technology, simple and convenient construction, and small amount of on-site work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

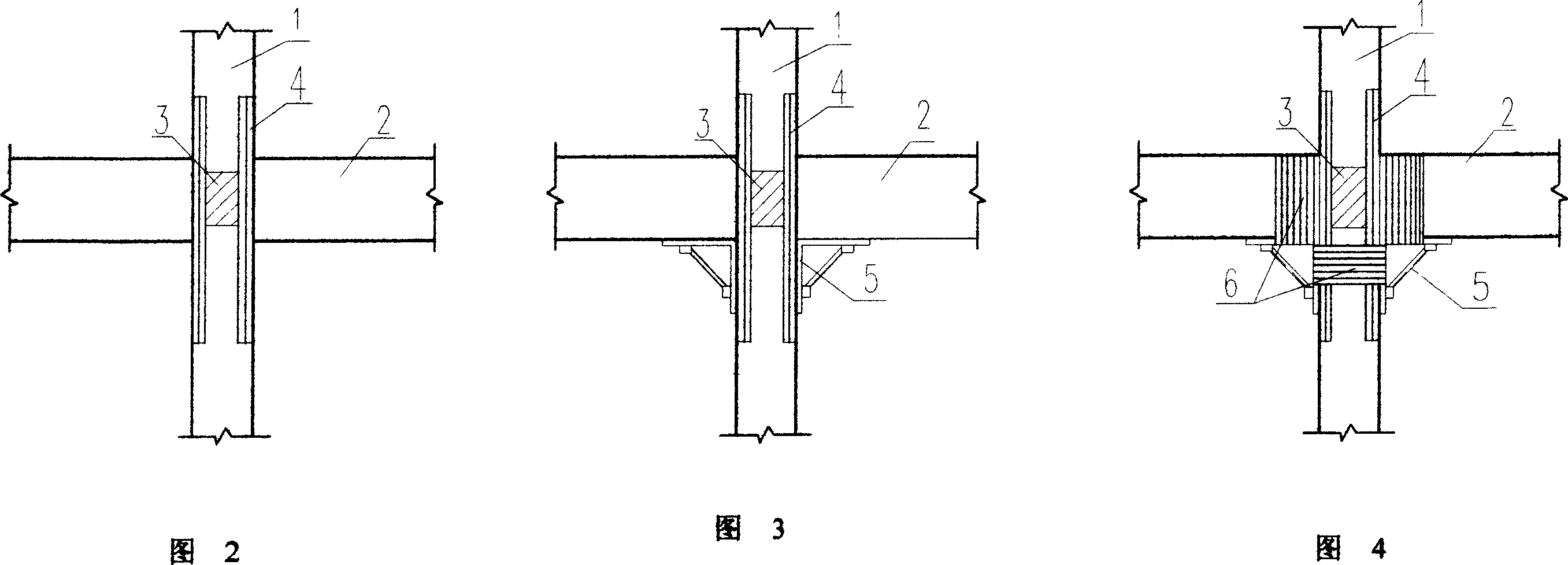

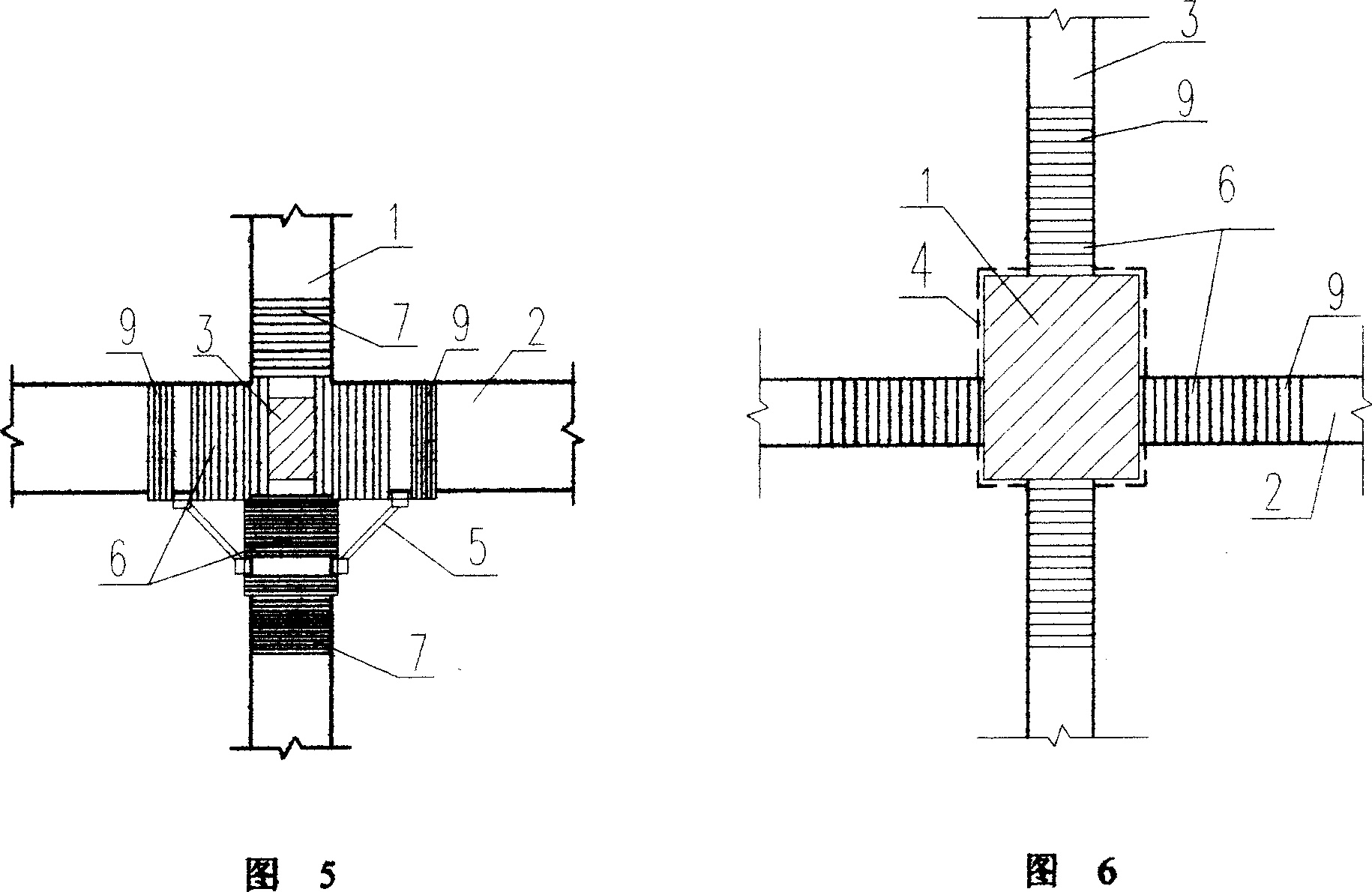

[0031] This embodiment is a node reinforcement method in which a column is orthogonal to four beams.

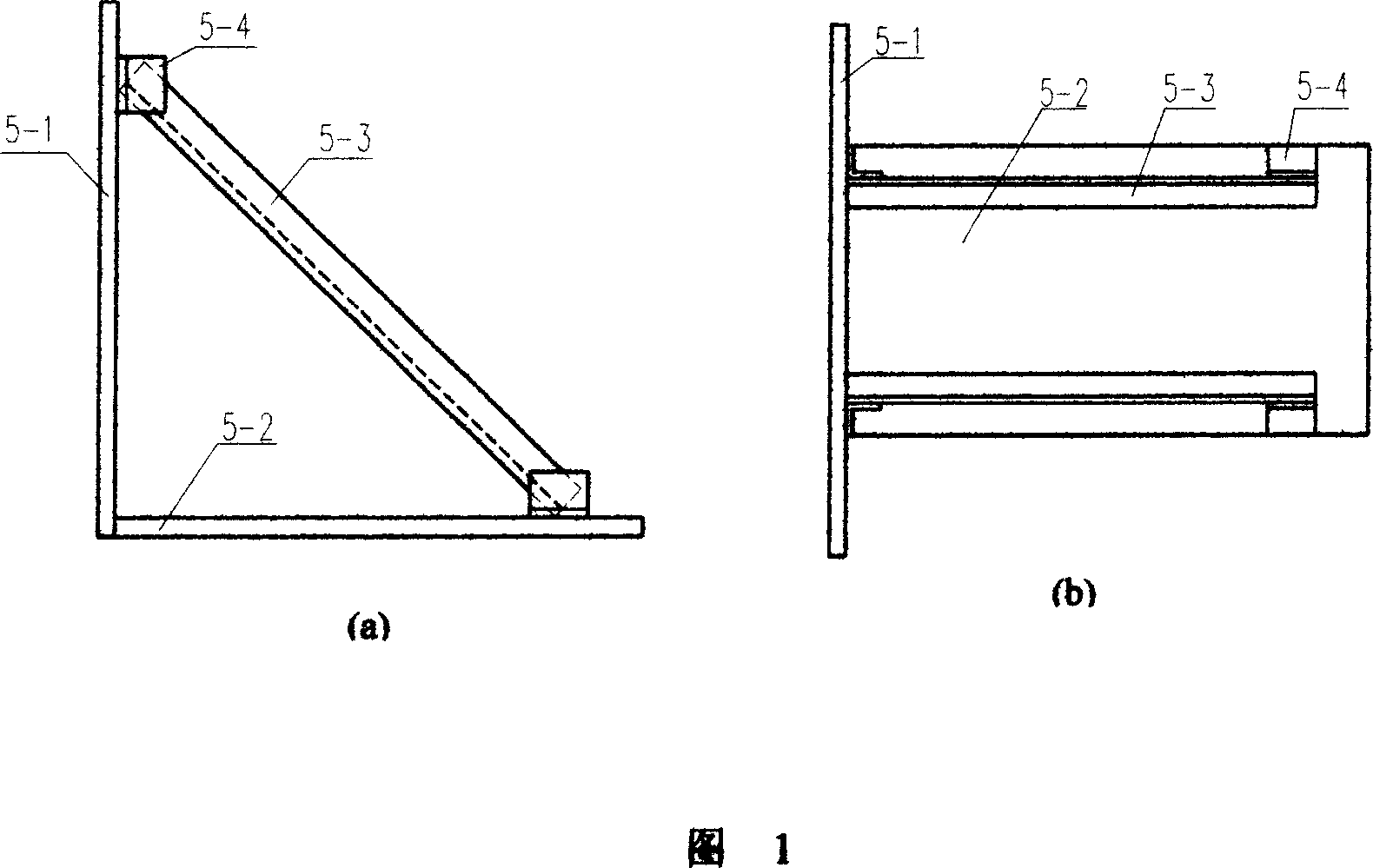

[0032] Referring to Fig. 1, four triangular steel haunches 5 are made earlier before construction. This triangular steel haunch 5 is mainly made up of a vertical haunch plate 5-1, a horizontal haunch plate 5-2 and two oblique bars 5-3. Both the vertical armpit plate 5-1 and the horizontal armpit plate 5-2 are 6mm thick steel plates, and the diagonal braces 5-3 are 45×5 equilateral angle steels. Among them, the vertical armpit plate 5-1 and the horizontal armpit plate 5-2 are welded vertically, and the two diagonal braces 5-3 are arranged in the right angle formed by the vertical armpit plate 5-1 and the horizontal armpit plate 5-2. The angle steel 5-4 is welded on the vertical axillary plate 5-1 and the horizontal axillary plate 5-2. The entire triangular steel armpit 5 is selected from A3 steel with good weldability. The width of the vertical haunch plate 5-1 and the hori...

example 2

[0041] This embodiment is a node reinforcement method in which a column is orthogonal to three beams.

[0042] Make 3 triangular steel haunches 5 before construction, and the specific manufacturing method is the same as Example 1. After prefabricating the triangular steel haunch 5, construct according to the following steps.

[0043] a. Grinding nodes. Grind away the mortar layer on the surface of beams 2 and 3 and column 1 around the nodes, and round the edges of beams 2 and 3 and column 1, then blow off the floating ash with high-pressure gas, and then clean it with acetone. The length of the area to be sanded is the same as in Example 1.

[0044] b. First, level the concrete surface polished and cleaned in step a with Swiss Araldite XH130 leveling glue, and then evenly apply a thin layer of Swiss Araldite XH7307 primer; after the primer is dry, proceed to the next step.

[0045] c. Use Swiss Araldite XH180 adhesive glue to vertically paste two layers of vertical carbon f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com