Method for preparing hydroxylquinoline aluminium of blue green type mixing ligand

A technology of hydroxyquinoline and mixed ligands is applied in the field of preparation of aluminum-based organic electroluminescent materials, which can solve the problems of short service life, performance decay, and unstable luminescence performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0155] The present invention will be further described below in conjunction with accompanying drawing:

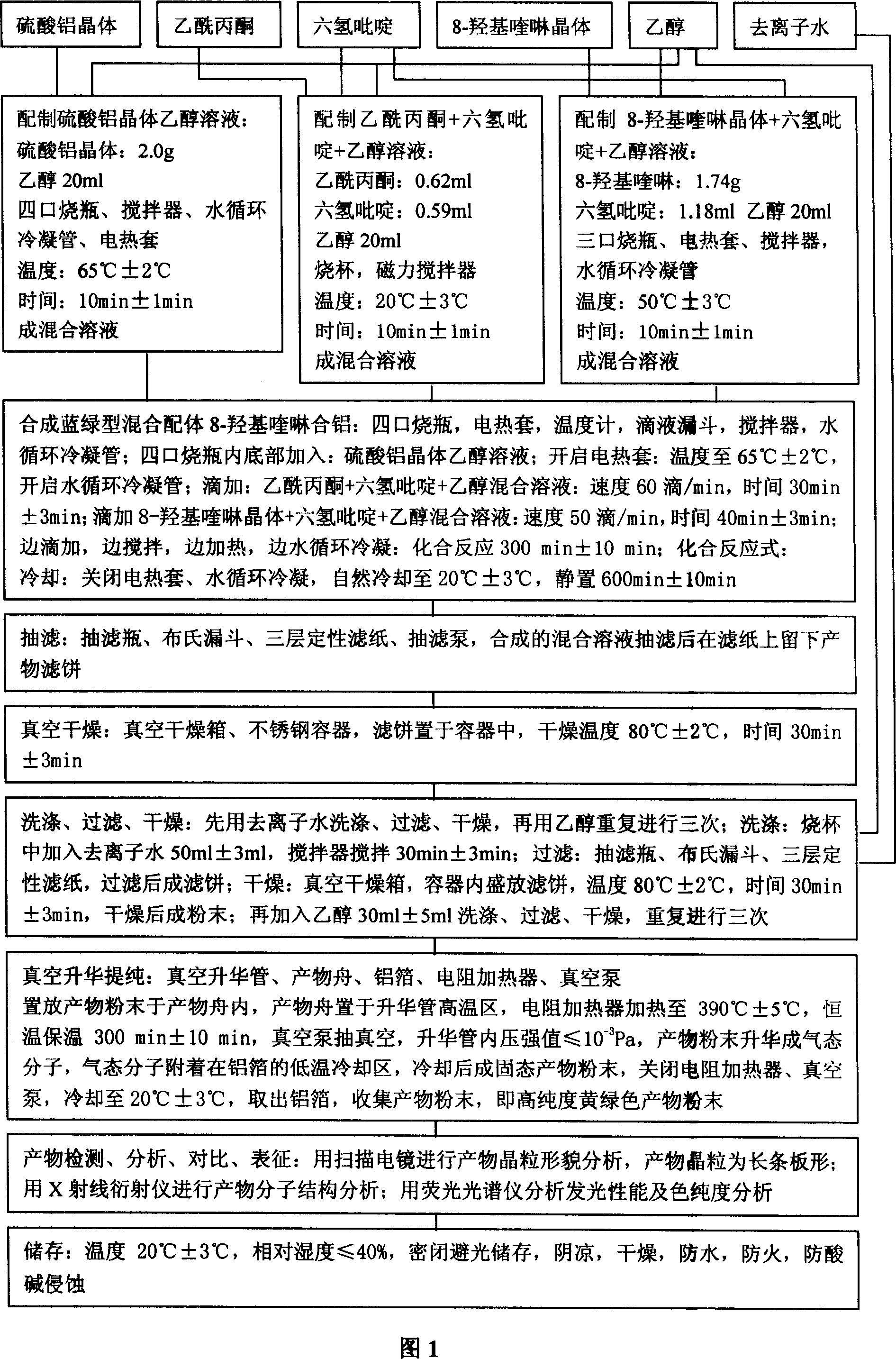

[0156] As shown in Figure 1, it is a flow chart of the preparation process, which must be carried out in strict accordance with the process parameters and operated in sequence.

[0157] The raw materials of the chemical substances required for the preparation must be strictly selected, and the purity shall be controlled, and no impurities shall intervene to prevent the formation of by-products, so as not to affect the luminescence performance of the product.

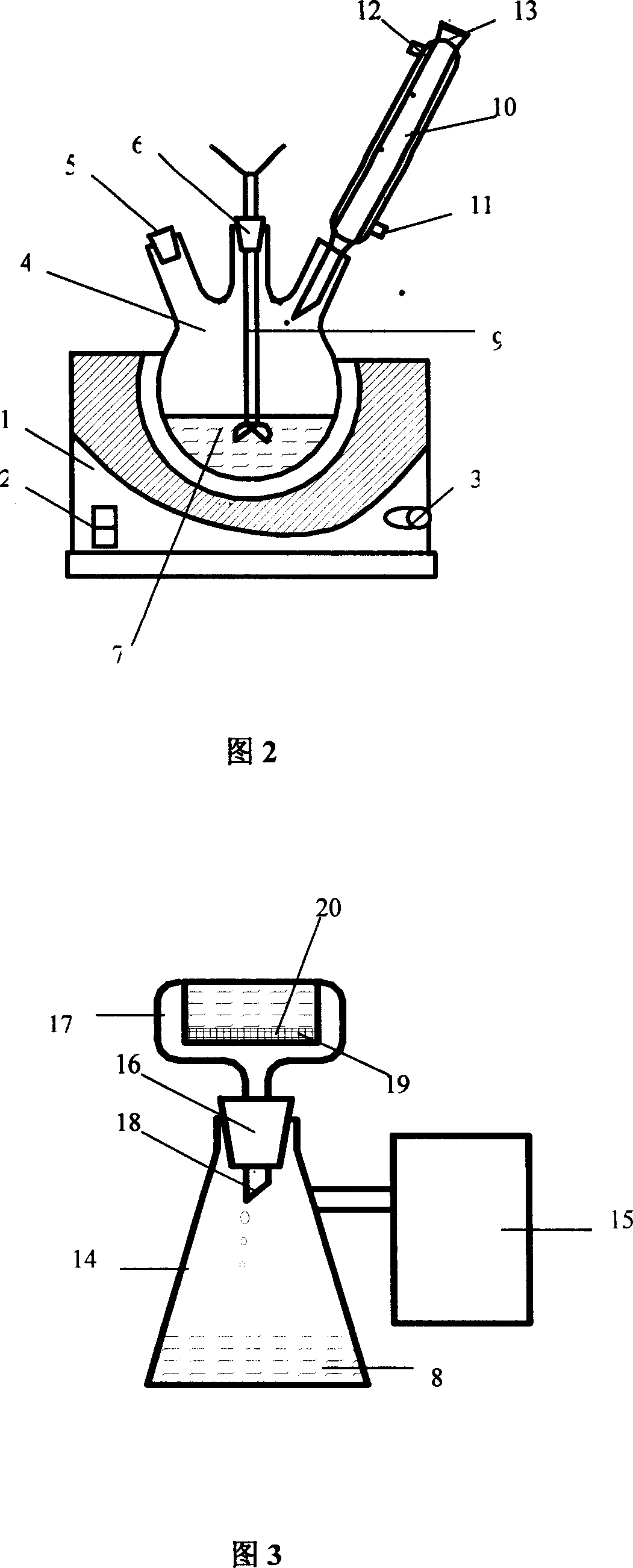

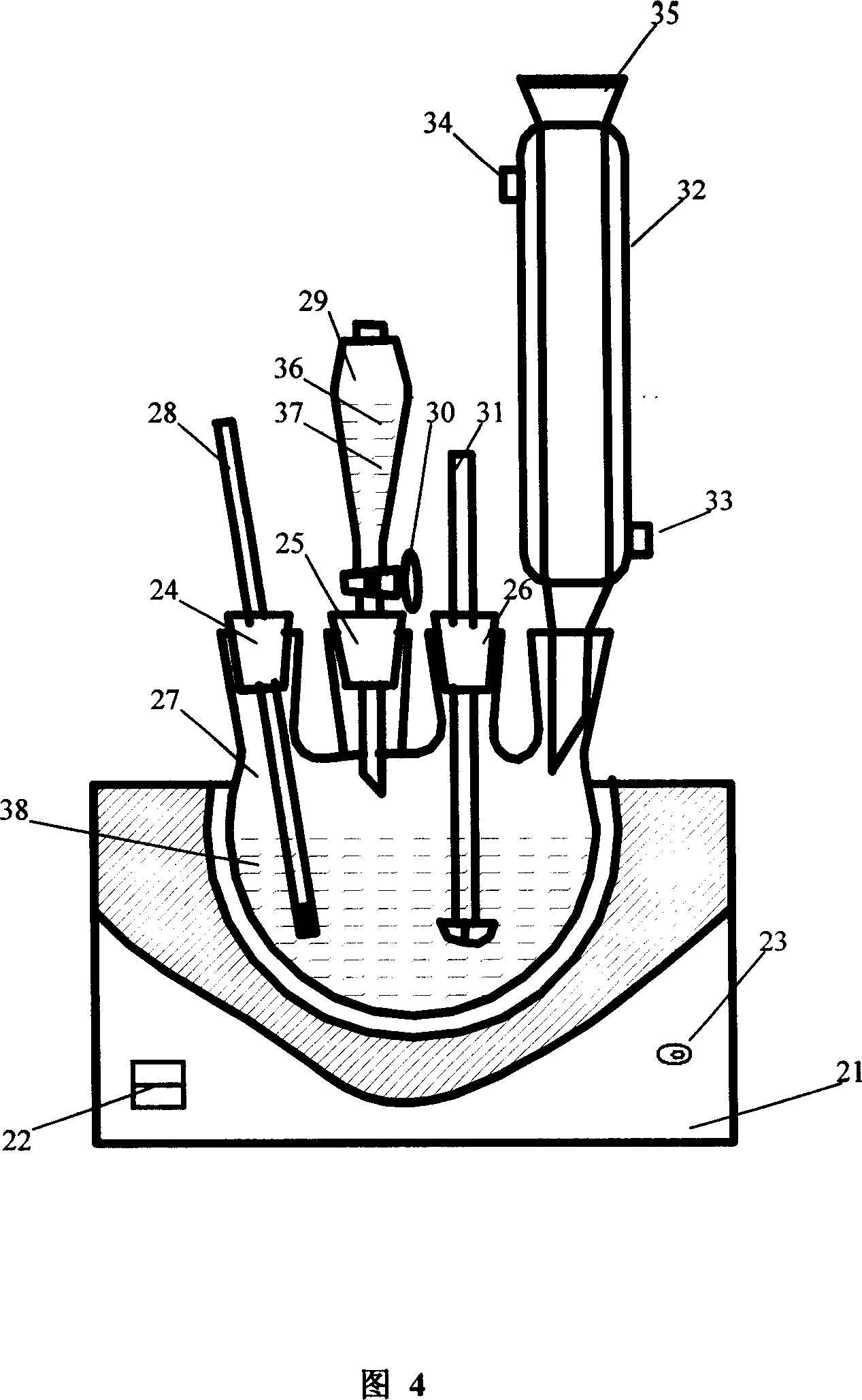

[0158] Three-necked flasks, beakers, four-necked flasks, suction filtration flasks, vacuum sublimation tubes, thermometers, stirrers, dropping funnels, water circulation condensers, Buchner funnels, qualitative filter papers, containers, vacuum ovens, and products used in the preparation process The boat, electric heating mantle, etc. should be kept clean, and no impurities should be allowed to intervene, so as not to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com