Method for molding pole type tool handle with reinforced core

A molding method and a technology for reinforcing cores, which are applied in the manufacture of tools, household utensils, hand-held tools, etc., can solve the problems of short service life, poor flatness, waste of wood, etc., and achieve long service life, good flatness, overcoming fragile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

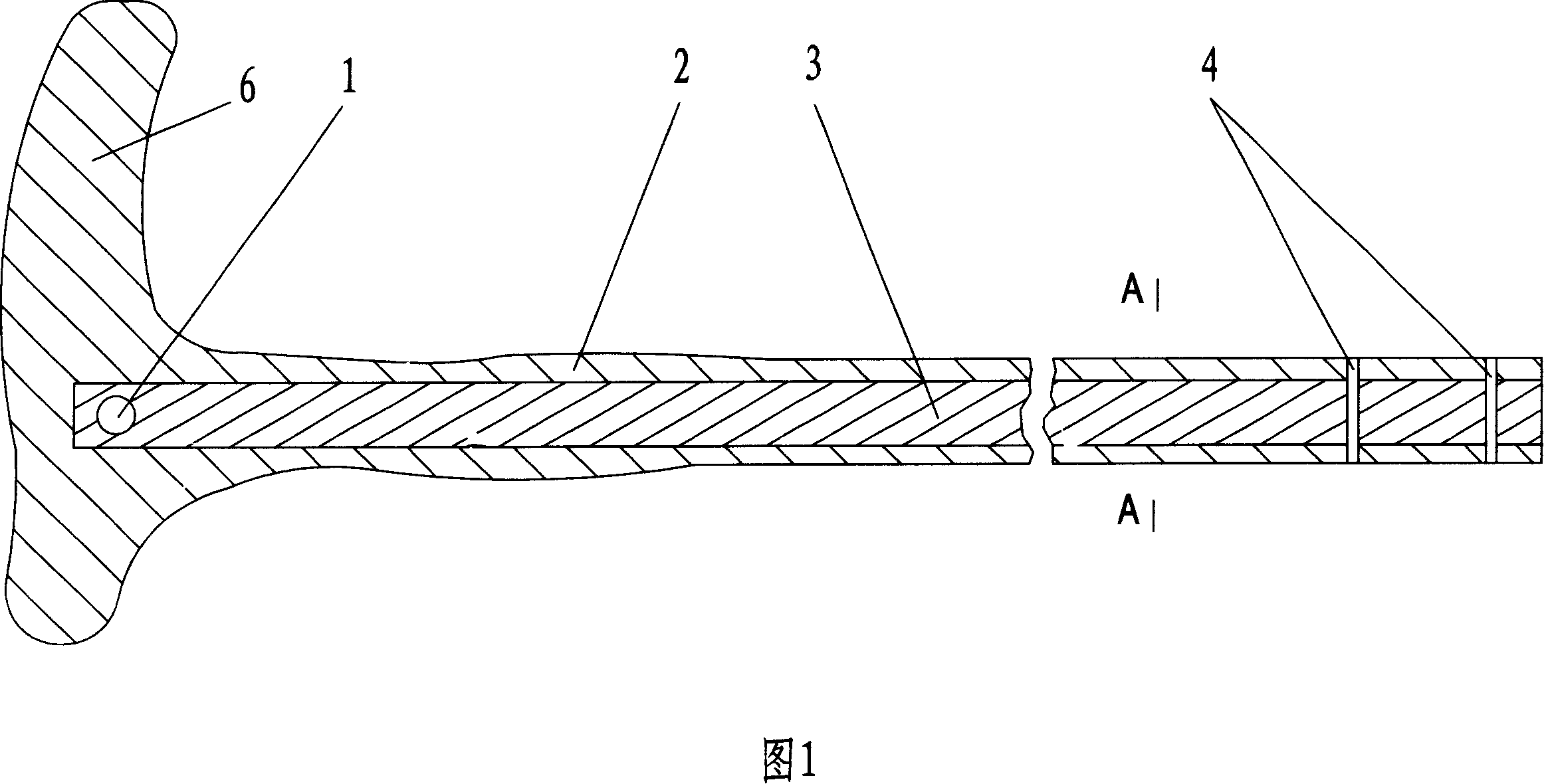

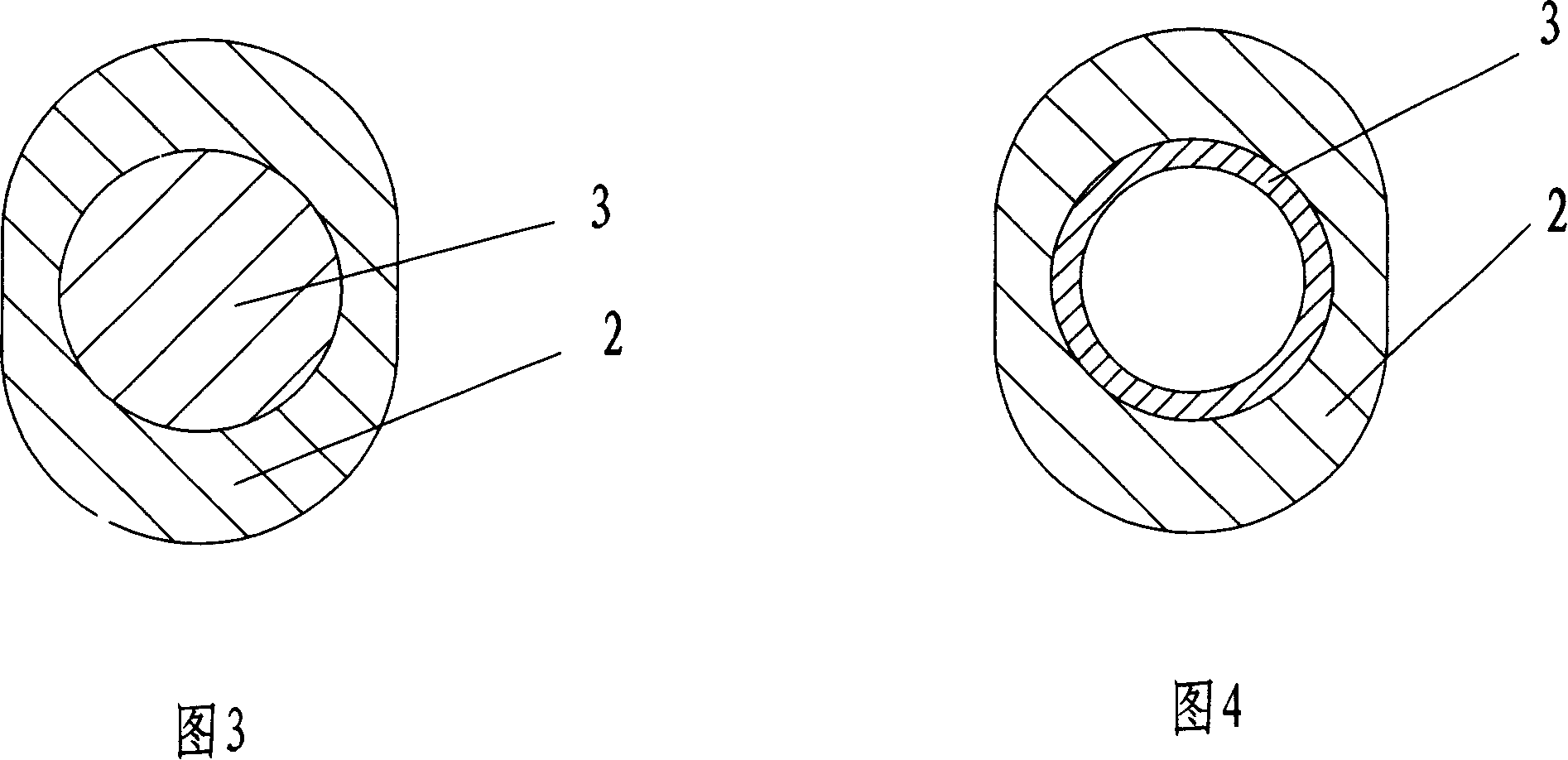

[0021] As shown in Figures 1, 3, and 5: first determine the length of the reinforcing core 3, which should be determined according to the length of the long rod-shaped handle to be produced, and the total length should be longer than the total length of the handle, that is, the length of the reinforcing core 3 There is a certain margin at the bottom, so that it stretches out from the bottom of the mold body 10,11. The material of the reinforcing core 3 is glass fiber reinforced plastics or natural materials or metal materials or plastics, as long as it can increase the strength. In this embodiment, thermosetting plastic rods are selected.

[0022] A mold hanging hole 1 is processed at the upper end of the reinforcing core 3, and the mold hanging hole 1 is transparent.

[0023] Put the reinforcing core 3 in the mold body 10, 11, and penetrate the hanging nail 14 fixed on the mold body 10, 11 into the hanging hole 1, so that the ends of the hanging nail 14 on both sides are in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com