Method and device for measuring pollutant discharging total of motor vehicle

A pollutant emission and measurement device technology, which is applied in the direction of measurement devices, vehicle testing, engine testing, etc., can solve the problems of large influence of zirconia oxygen sensor, large dilution ratio error, error, etc., and achieve high exhaust gas detection accuracy, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

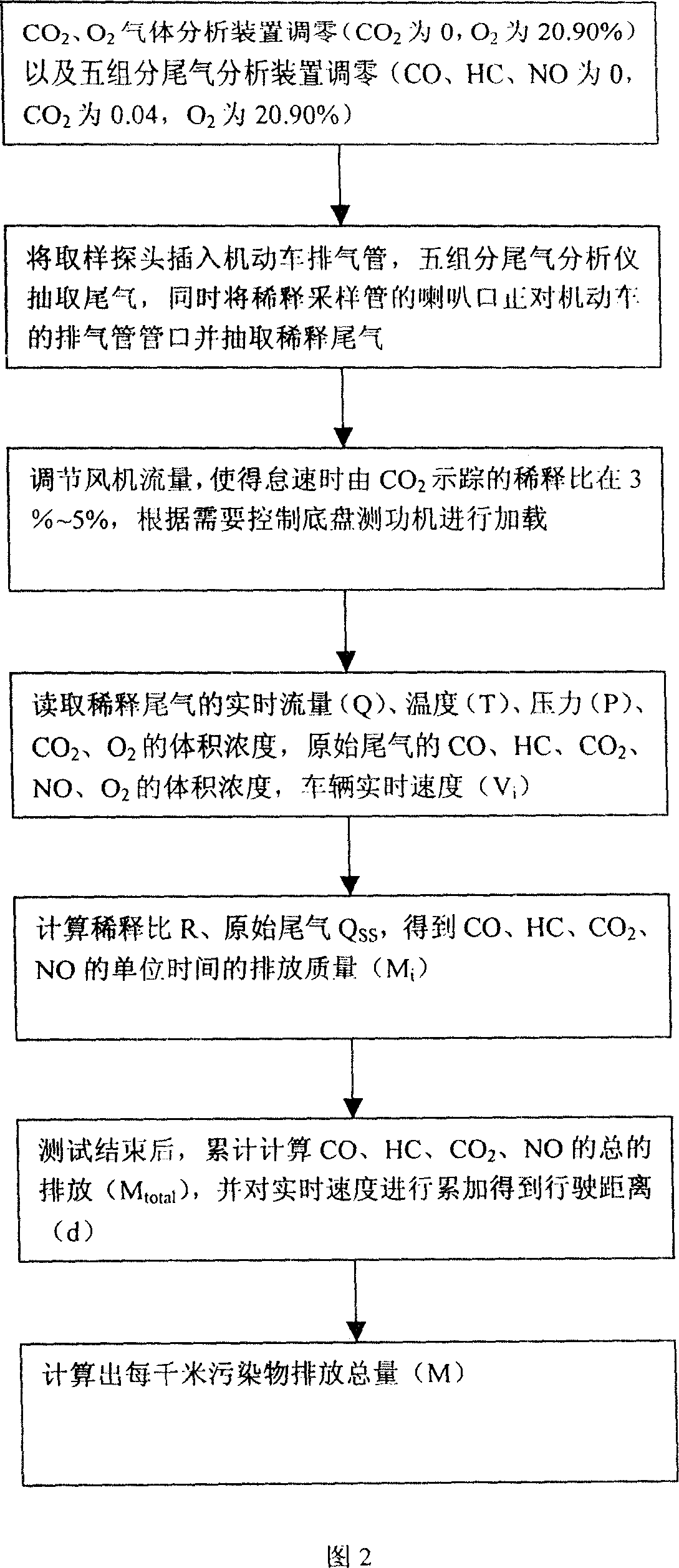

[0016] Referring to Fig. 1, the inlet of the diluted sampling pipe 2 with bell mouth is connected to the exhaust pipe of the motor vehicle under test, the outlet is connected to the fan 3, the fan 3 is connected to the fan flow regulating device 4, and the control interface of the computer measurement and control system 9 is connected to the chassis dynamometer 1 and fan flow regulating device 4, flow, temperature, pressure measuring device 5, five-component tail gas analysis device 6, O 2 Gas analysis device 7, CO 2 The interface of the gas analysis device 8 is connected to the computer measurement and control system 9 . The output end of the sampling probe 10 is connected to the five-component exhaust gas analysis device 6, and the input end is located in the exhaust pipe of the motor vehicle.

[0017] o 2 Gas analysis device 7, CO 2 The gas analysis device 8 samples from the rear sampling port of the flow, temperature and pressure measuring device 5, and directly measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com