Longspan bridge erecting apparatus and erecting method thereof

A large-span, bridge technology, applied in the field of transportation, can solve the problems of complex structure, limited height, inconvenient transportation, etc., and achieve the effect of simple erection process, good stability and low operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] work process description

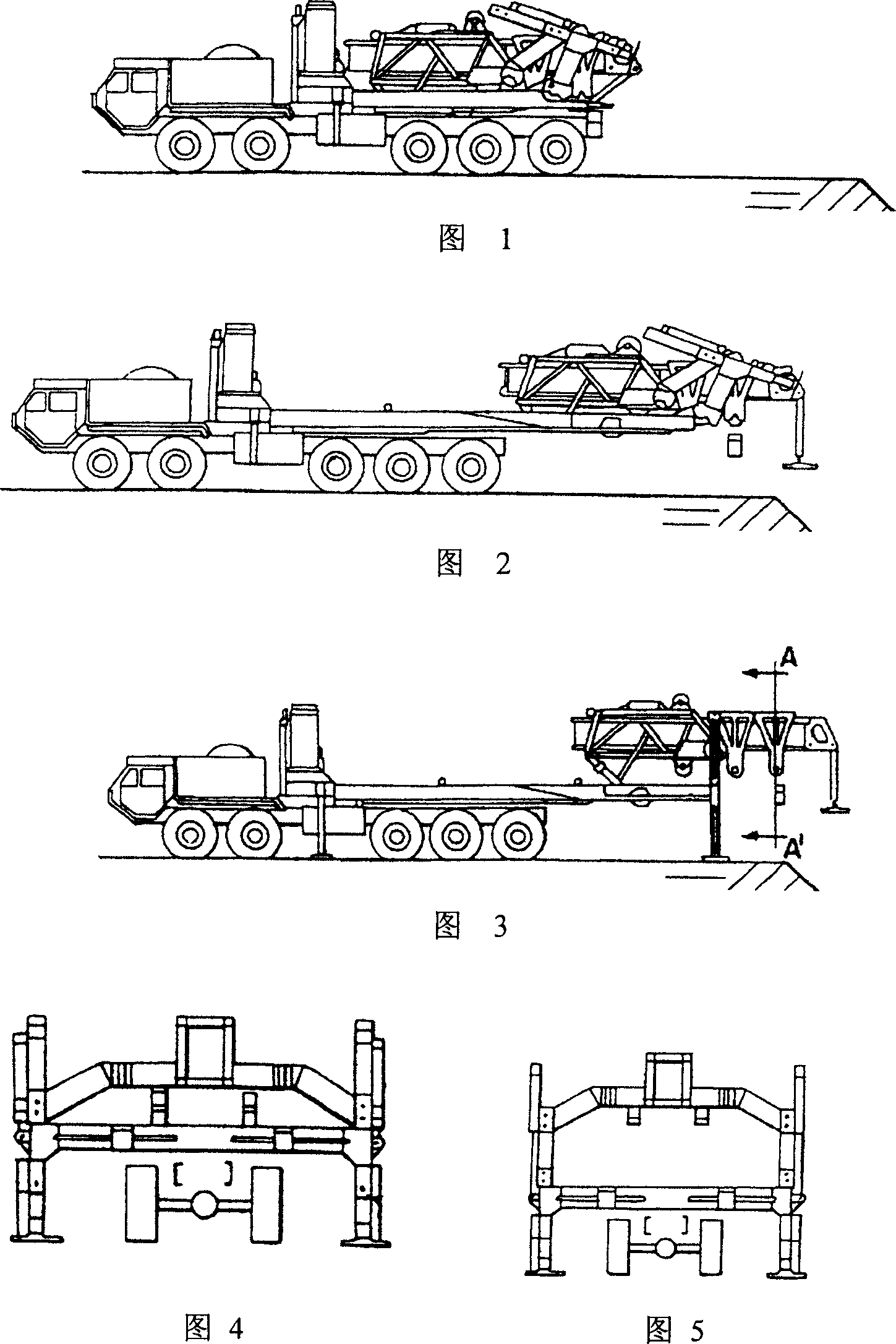

[0065] 1. Put the bridge car in place, put down the balance outrigger on the mobile frame, adjust the height of the guide beam support, lift a middle bridge section and place it on the guide beam sleeve through the folding arm crane, as shown in Figure 20.

[0066] 2. The chassis car is in neutral, and the horizontal pin is withdrawn through the oil cylinder. The motor pushes the chassis car forward to the front of the car, so that the mobile frame moves out of the slideway. One end of the beam sleeve is hinged with the beam of the balance outrigger, and the other end is connected with the small slideway of the erection platform by two sets of rollers to form two supporting points, that is, the entire erection platform is built. Figure 21.

[0067] 3. Put down the front balance outrigger of the folding arm crane, and adjust the height of the front and rear outriggers according to different terrains; in order to facilitate the connection of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com