Low density converter steel tapping slag bridge

A low-density, converter technology, used in the manufacture of converters, etc., can solve the problems of difficult to achieve common refractories, discounted slag retainers, different expansion coefficients, etc., to suppress eddy, short tapping time, and increase stability. and durability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

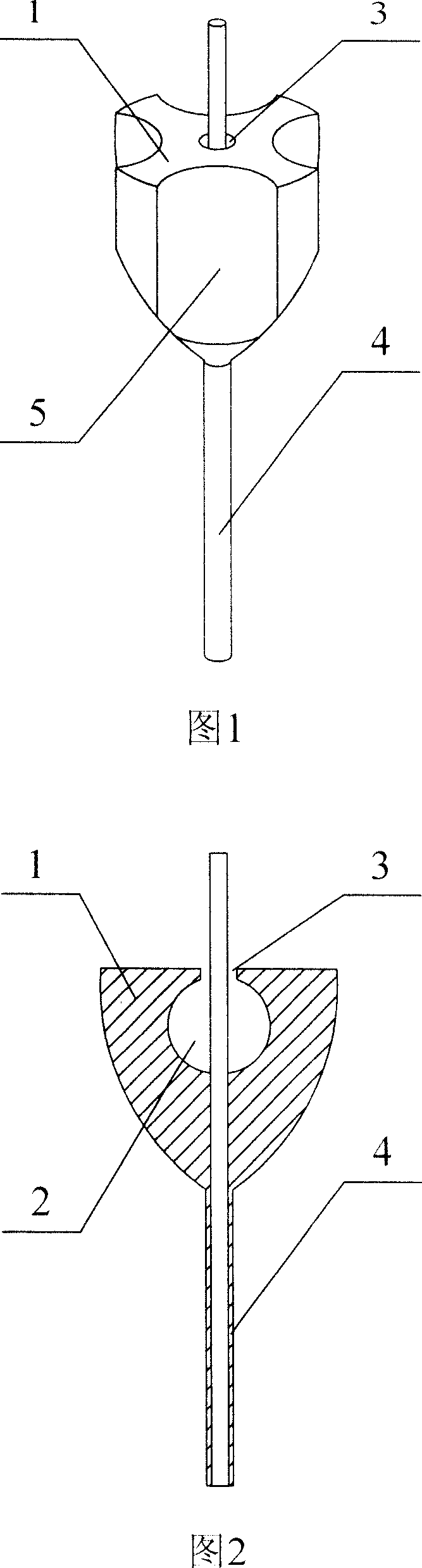

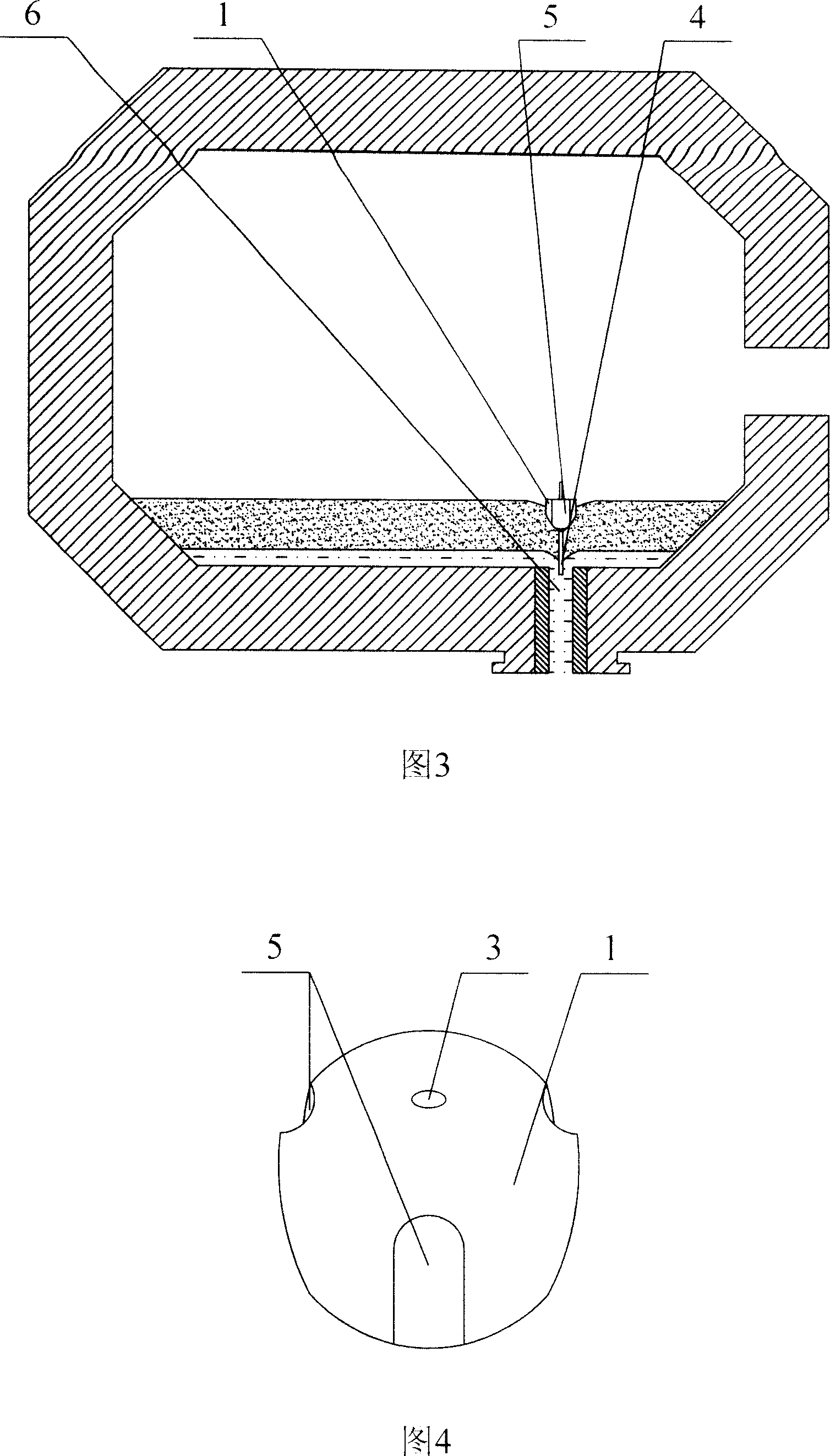

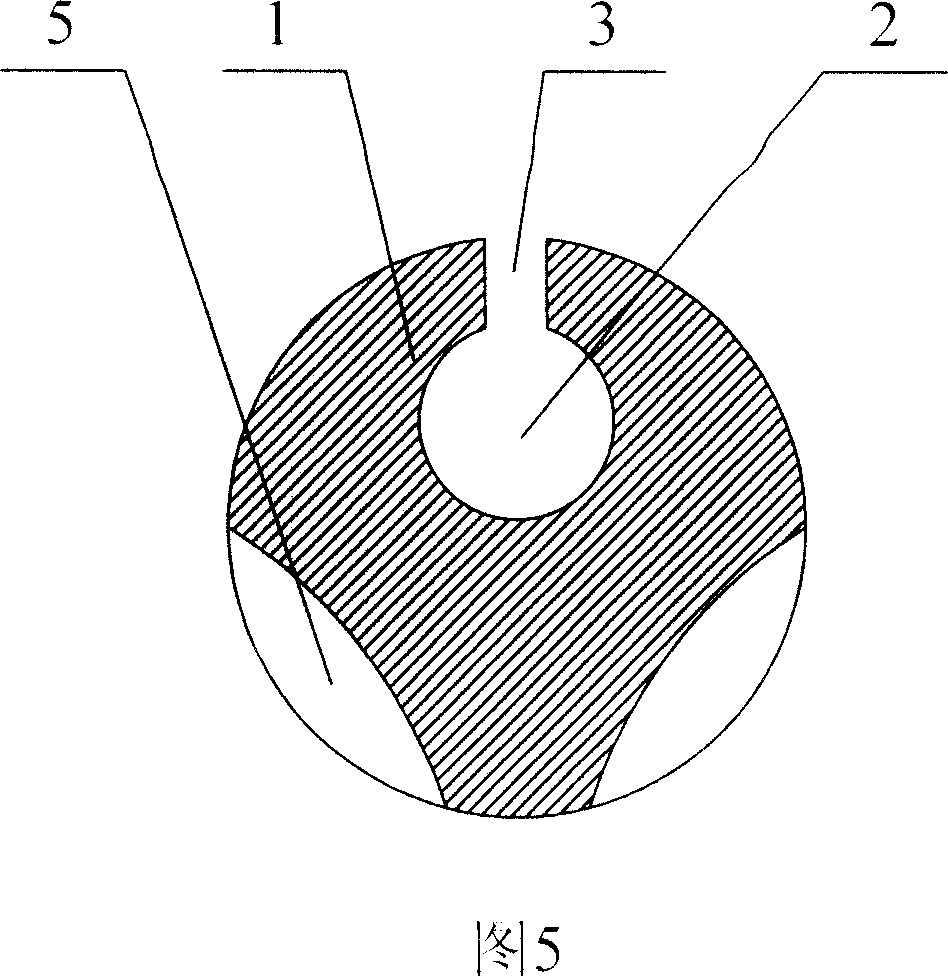

[0018] The low-density converter tapping slag stopper shown in Figures 1-2 has a rotary slag stopper 1 made of ordinary refractory materials with the center of gravity located on the vertical line. The rotary slag stopper 1 can be inverted Conical, hemispherical or gyro-shaped, the gyro-shaped slag retaining body 1 is shown in this illustration. The upper half of the gyro-shaped slag retaining body 1 is provided with a circular cavity 2 which is symmetrical to the mid-perpendicular and shifts its center of gravity downward. The circular cavity 2 is provided with a ventilation hole 3 leading to the top surface of the gyro-shaped slag retaining body 1 along the mid-perpendicular line. On the vertical line of the gyro-shaped slag-stopping body 1, there is a center rod 4 that penetrates up and down. The upper end of the center rod 4 passes through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com