Control method of digital pulse consumable electrode gas protection welding

A technology of pulse melting electrode and gas shielded welding, which is applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems that the closed-loop control of the droplet transfer process cannot be realized, the droplet transfer process has not been realized, and has not yet been discovered. Achieve powerful data processing capabilities, high adjustment accuracy and adjustment sensitivity, and ensure the effect of welding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

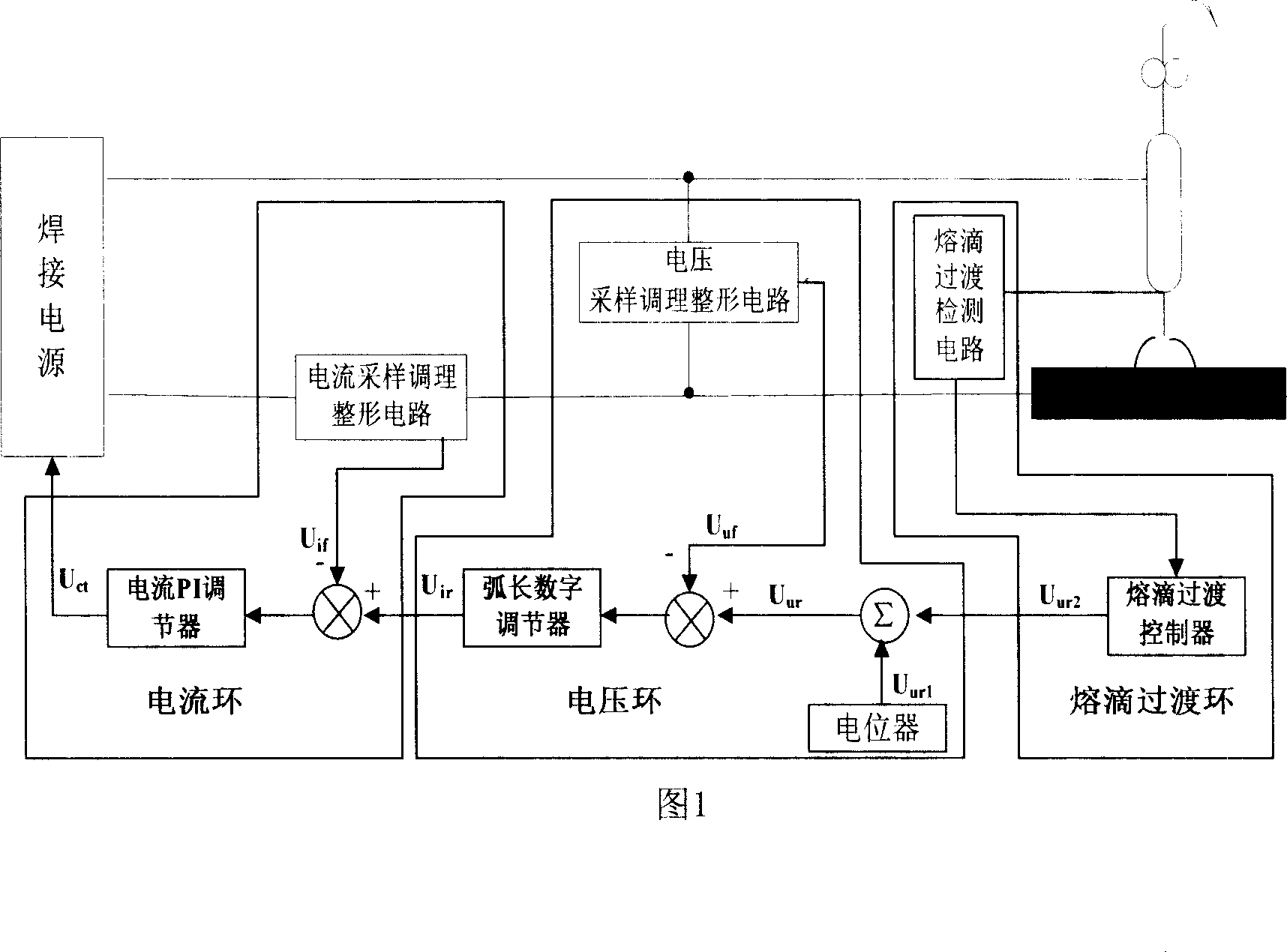

[0014] The surfacing test of low carbon steel plate was carried out with 1.2mm H08Mn2Si welding wire, and the welding voltage target value U ur1 24V, welding current target value U ir 100A. As shown in Figure 1, the target value of the arc voltage U ur Consists of two parts, one of which is U ur1 , the other part is U ur2 ;Target value U of the current ir . The control signal U of the power circuit ct Calculated by the software during the welding process, the arc voltage feedback U uf , the current feedback value U lf It is sent into the DSP through the hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com