Transmission mechanism of combing machine detaching roller

A technology for separating rollers and transmission mechanisms, which is used in combers, transmission devices, gear transmission devices, etc., can solve the problems of low motion accuracy, increased cost, and difficulty in design and calculation, and achieves improved transmission control accuracy and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

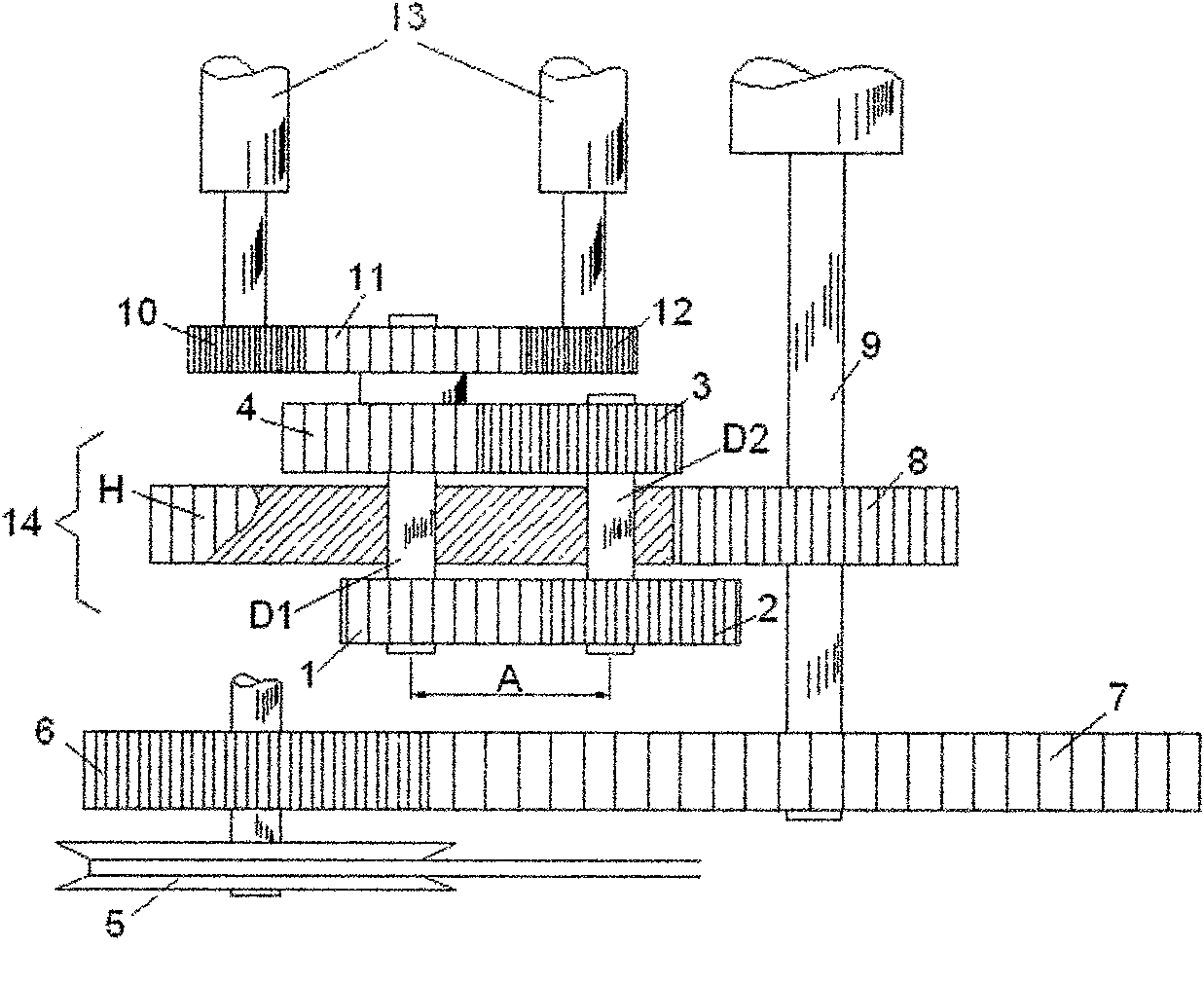

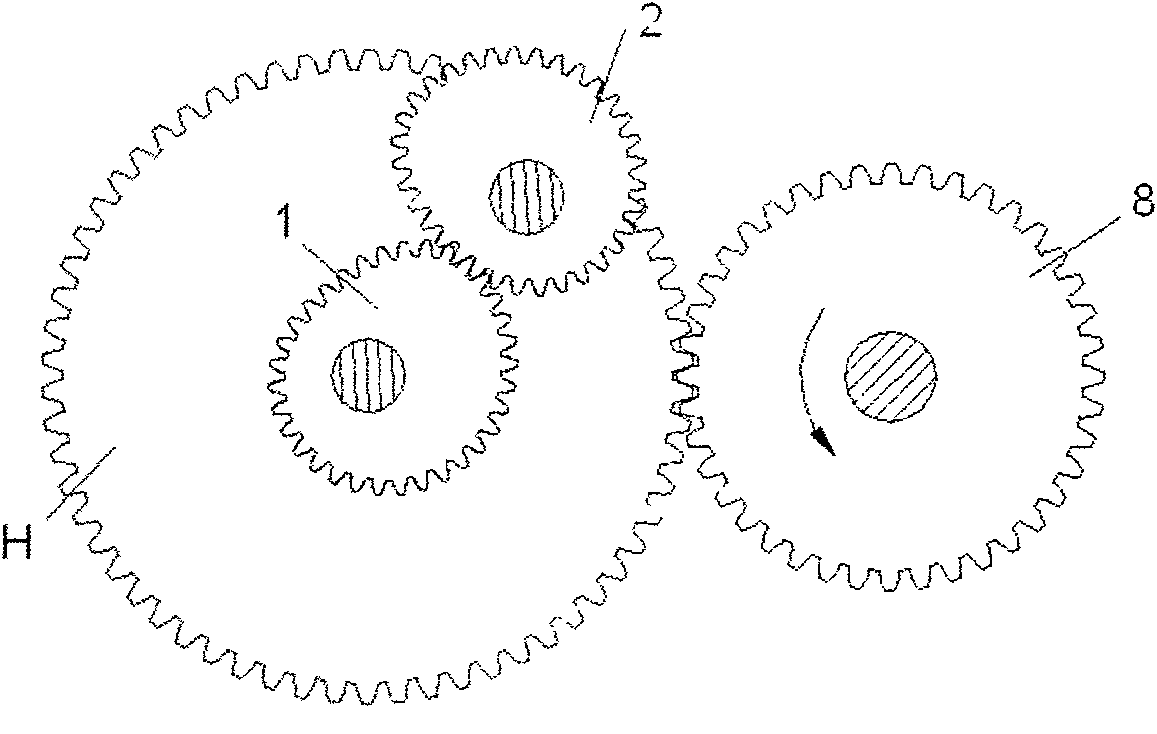

[0017] like figure 1 As shown, the cylinder shaft 9 is driven by the pulley 5 through the gear 6 and the gear 7. The gear 8 fixed on the cylinder shaft 9 drives the tie rod H to rotate at a constant speed around the axis D1. The front planetary wheel 2 and the rear planetary wheel 3 revolve around the axis D1 at a constant speed along with the tie rod H, and at the same time rotate around the axis D2.

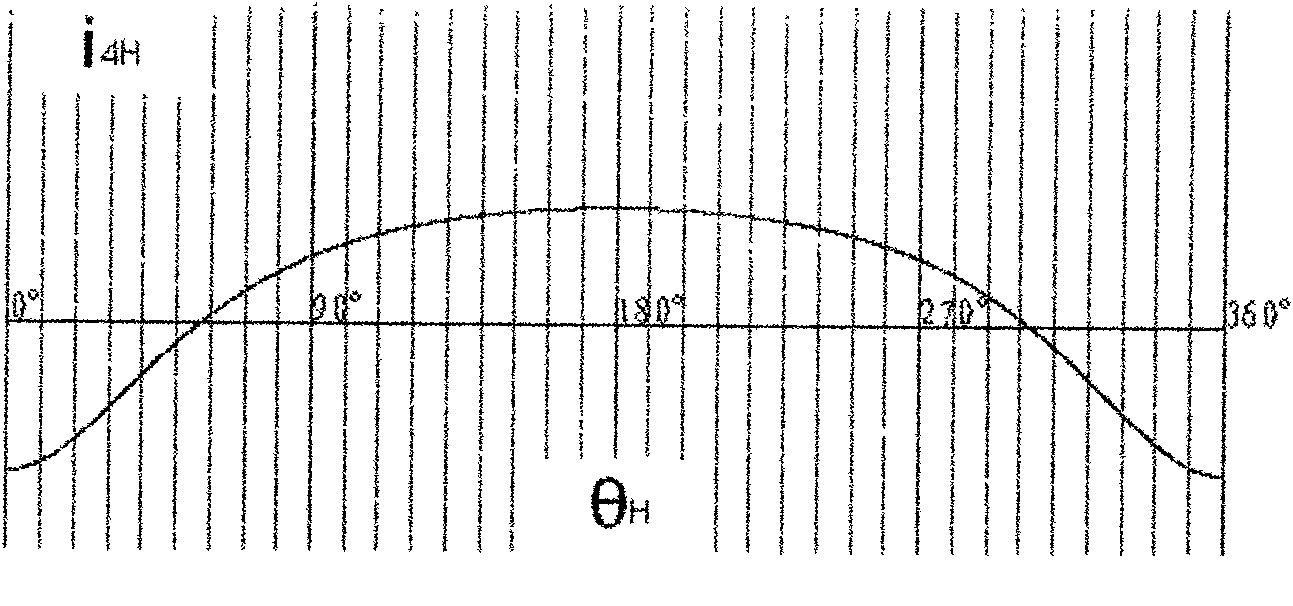

[0018] The sun gear 1 is fixed on the frame (not shown) and does not rotate, and the front planetary gear 2 and the rear planetary gear 3 are rigidly connected with the shaft D2. The rotation angular speeds of the front planetary gear 2 and the rear planetary gear 3 are the same and constantly changing, thereby driving the rear sun gear 4 to change speed and direction to rotate. And then drive gear 10, gear 12 by the gear 11 that is connected with rear sun gear 4 and shift speed, change direction and rotate and transmit to separating rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com