Probe for an atomic force microscope

An atomic force microscope, a microscope technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve problems such as inability to measure interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

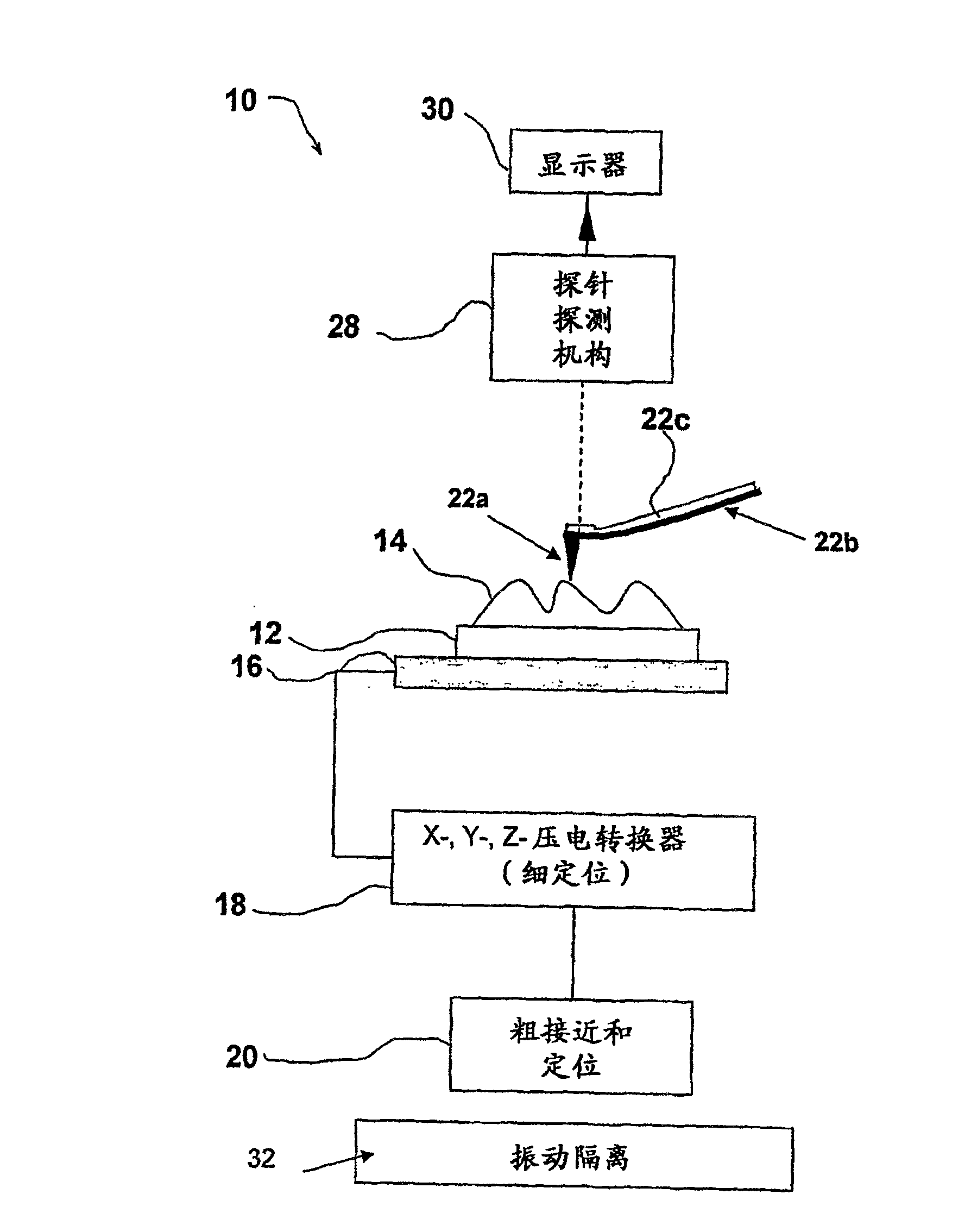

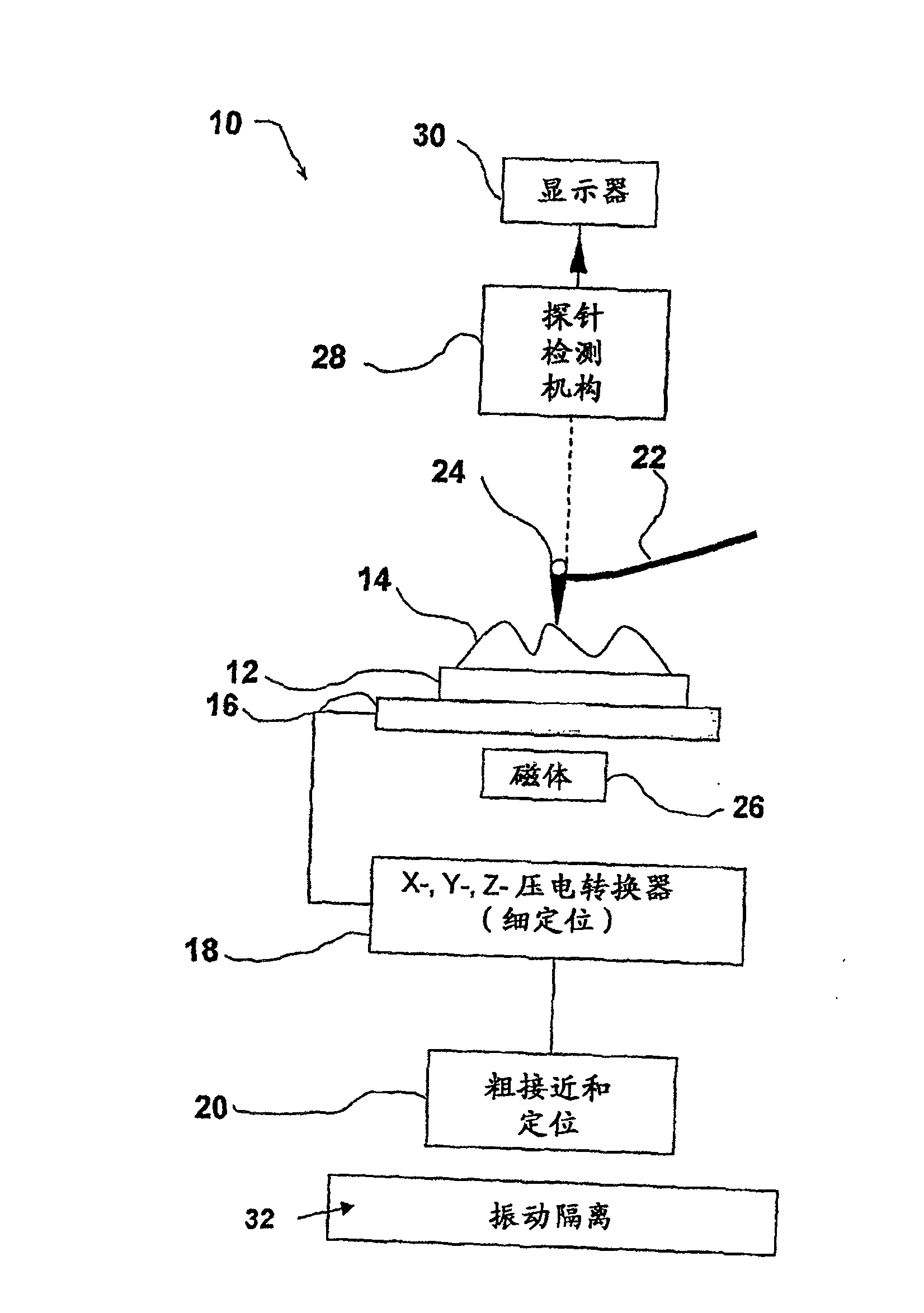

[0046] reference figure 2 A schematic implementation of the AFM indicated generally by 10 is shown, which uses a first embodiment of a probe constructed in accordance with one aspect of the present invention. The illustrated AFM device 10 includes a flat plate 12 suitable for carrying a sample 14 and mounted on a fork arm of a tuning fork 16. The tuning fork 16 is connected to the piezoelectric transducer 18 and the coarse drive device 20. Piezoelectric transducer 18 is used to drive sample 14 (together with plate 12 and tuning fork 16) in the three dimensions x, y, and z directions. In the art, the z-axis of the Cartesian coordinate system is generally perpendicular to the plane occupied by the sample 14. That is, the interaction force depends not only on the xy position (imaged pixel) of the probe 22 above the sample 14, but also on its height above. The tuning fork control (not shown) is arranged to apply a sinusoidal voltage to the tuning fork 16 to excite resonance or n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com