Compressor

A technology of compressors and motors, applied in the field of compressors, can solve the problems of increasing compressors and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

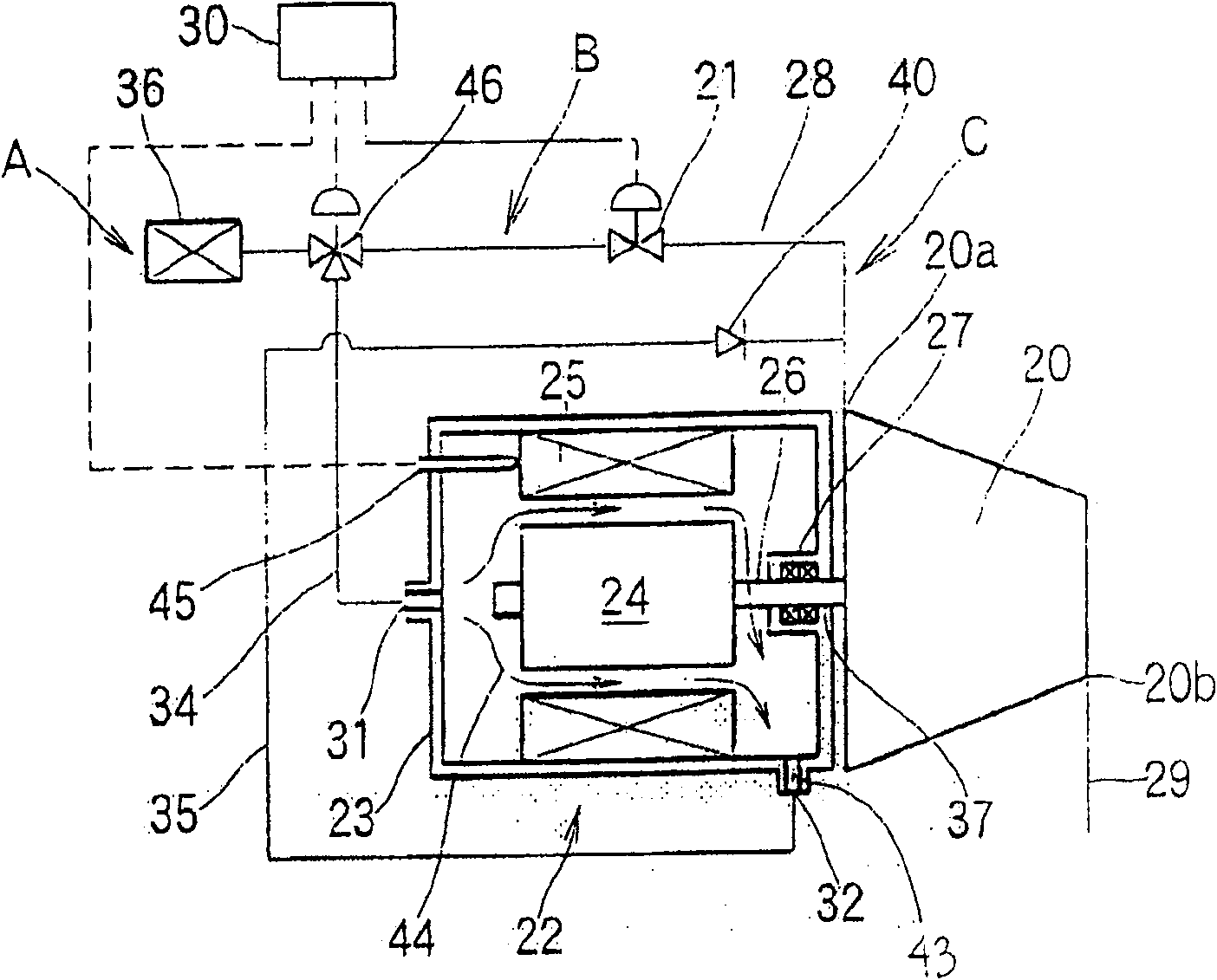

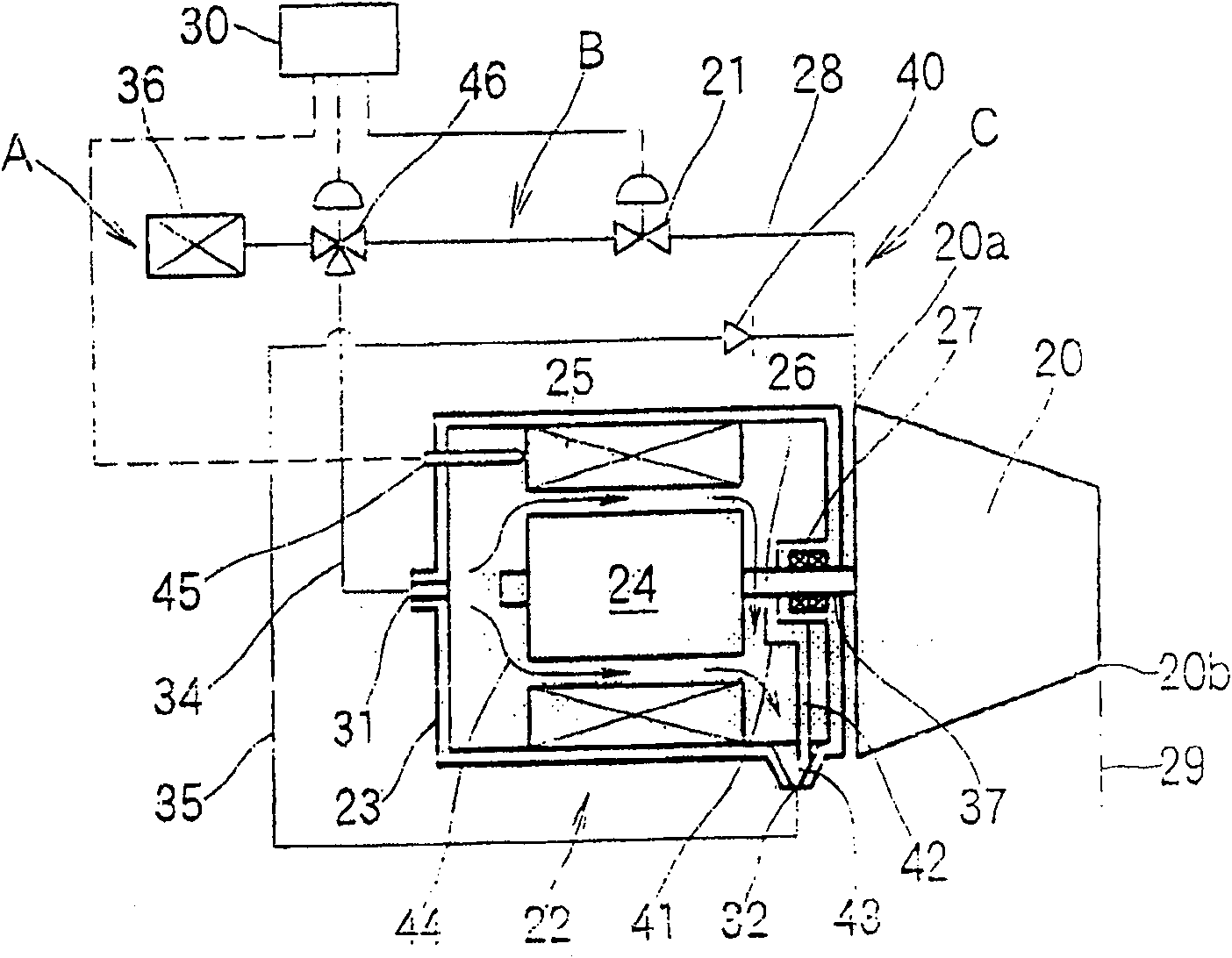

[0016] First, adopt as its cooling system diagram the figure 1 The compressor according to Embodiment 1 of the present invention will be described. This type of compressor has a compressor main body 20, which has a structure in which a pair of male and female screw rotors (not shown) engage and are rotatably accommodated inside a rotor housing. A suction flow path 28 is connected to the suction port 20a of the compressor main body 20, and a discharge flow path 29 is connected to the discharge port 20b. Also, one of the aforementioned pair of male and female screw rotors (usually a male rotor) constituting the compressor main body 20 is connected to a drive shaft 26 of an electric motor 22 .

[0017] By rotating the screw rotor with the motor 22 , the compressor main body 20 compresses the gas supplied from the suction flow path 28 and discharges it into the discharge flow path 29 as high-pressure fluid. The electric motor 22 is composed of a stator 25 fixed to the inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com