Bucket with crashing lid and its crashing method

A bucket and pulverized material technology, applied in mechanically driven excavators/dredgers, grain handling, etc., can solve problems such as drive motor failure, inability to effectively prevent pulverized objects from flying, etc. The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

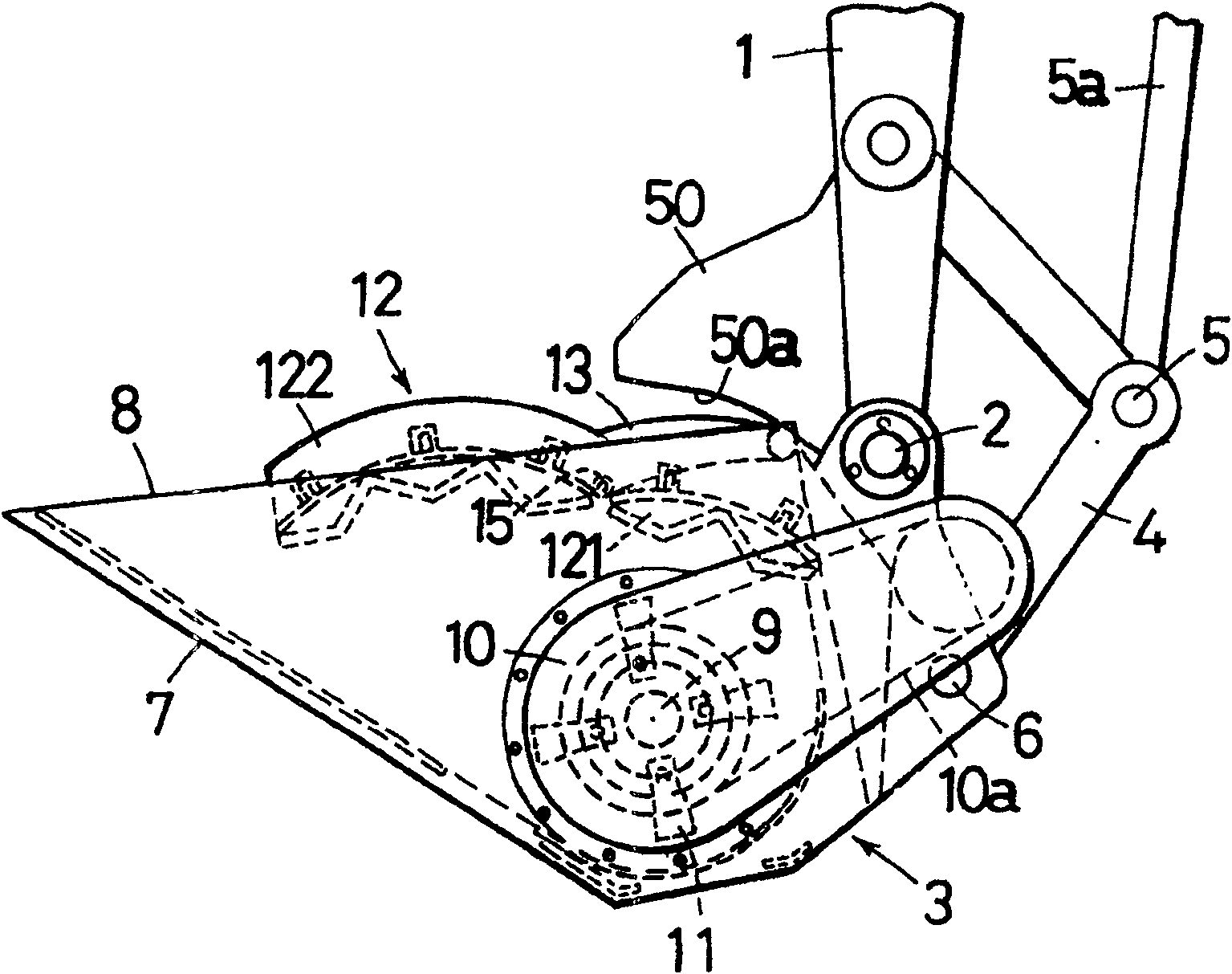

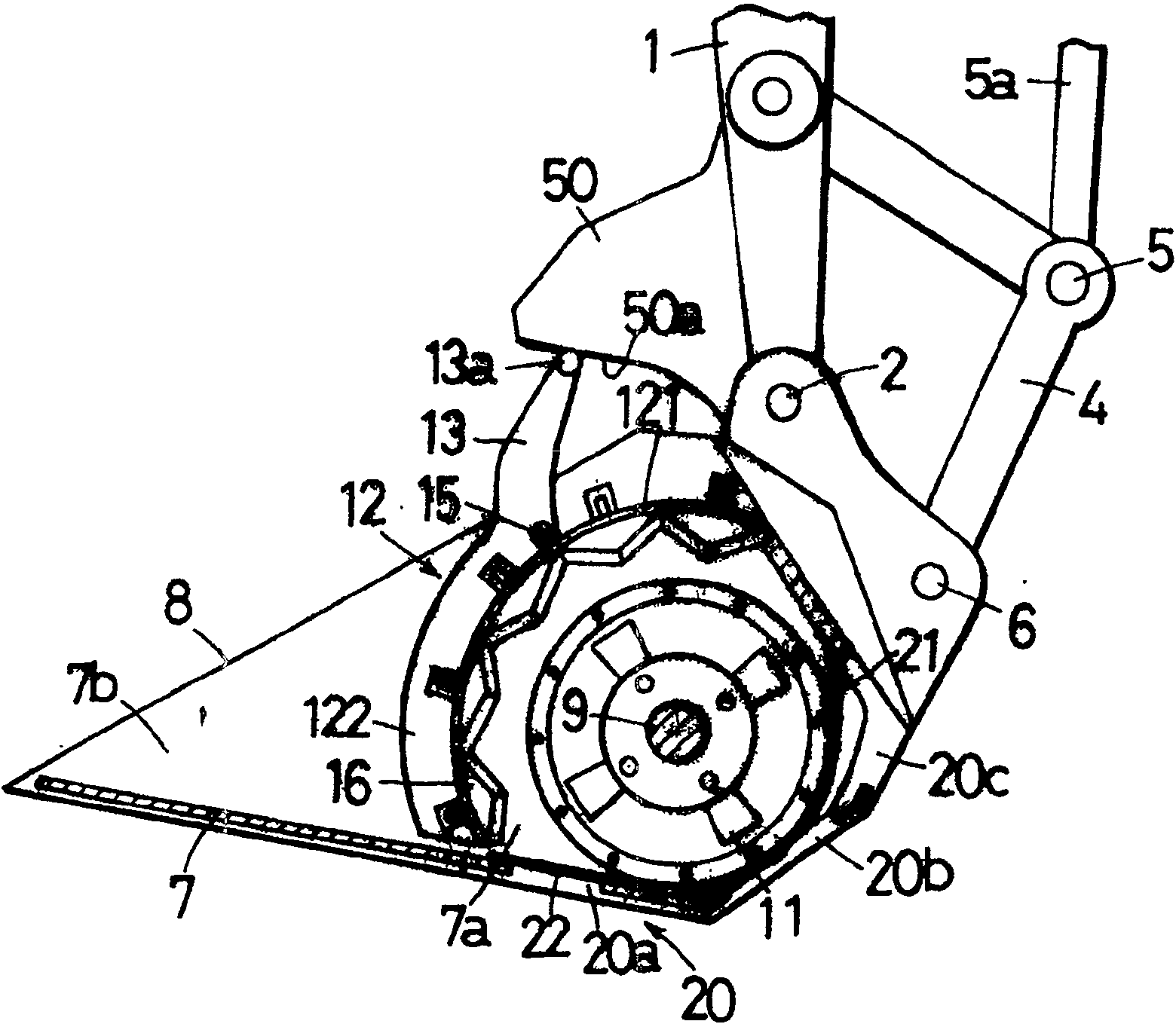

[0043] Embodiment 1 of the present invention will be described in detail with reference to the drawings. figure 1 It is a side view of the bucket with a crushing cover of the present invention. figure 2 , image 3 is the same as figure 1 The corresponding side cross-sectional views are explanatory views showing the start state of the scooping operation and the end state of the scooping operation by the bucket with the crushing cover, respectively. Figure 4 It is a side view of the crushing cover, showing the state that the backlash plate bushing is installed on the inner wall and the first scattering prevention member is installed on the side wall. Figure 5 It is a side view of the crushing cover, showing the state where the backlash plate bushing is attached to the inner wall and the second scattering prevention member is attached to the front end. Image 6 It is an explanatory diagram showing a state where the crushing cover to which the first scattering preventing mem...

Embodiment 2

[0073] according to Figure 9 , 10 , to describe Embodiment 2 of the present invention in detail. In addition, the same code|symbol is attached|subjected to the same part as Example 1, and the detailed description is abbreviate|omitted. Figure 9 , Figure 10 It is a side view of a bucket with a crushing cover, which is equivalent to Example 1 figure 2 , 3 is an explanatory diagram showing the start state of the scooping operation and the end state of the scooping operation by the bucket with a crushing cover in Example 2.

[0074] A pulley 51 with fixed teeth is fixed to the arm 1 . The axis of the belt pulley 51 with fixed teeth is consistent with the axis of the support shaft 2 . A toothed pulley 52 is fixed to the shaft 15 for swinging the crushing cover 112 . A toothed belt 53 is wound between the toothed pulley 51 and the toothed pulley 52 . On the shaft 15, a crushing cover 112 is fixed. When the shaft 15 swings, the crushing cover 112 swings to open and close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com