Method for coating silicon nitride film layer on piston ring surface

A technology of silicon nitride film and surface coating, which is applied in the direction of piston ring, coating, metal material coating process, etc., to achieve the effect of prolonging life, improving performance, widely promoting value and application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

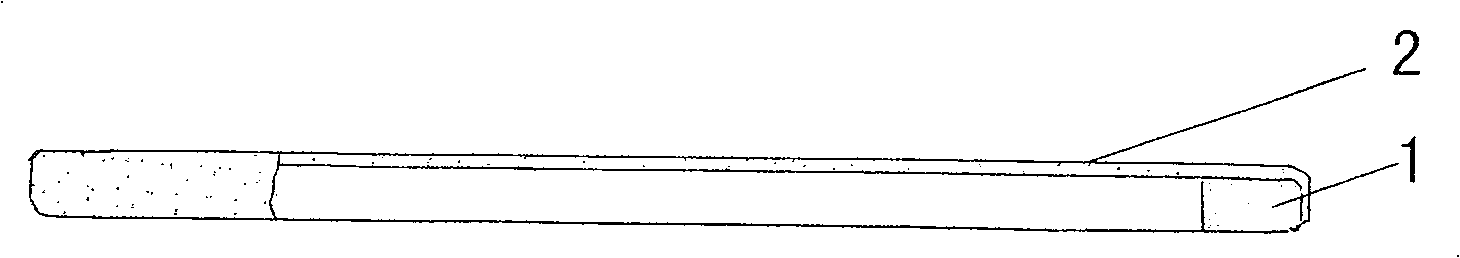

Image

Examples

Embodiment 1

[0019] The ordinary piston ring is polished with a DJP-II electrolytic polishing machine, the purpose is to improve the surface finish of the piston ring to be deposited and remove the oxide skin on the surface. Put the polished piston ring in an ultrasonic cleaner for 15 minutes, take it out and clean the surface with acetone. Then put the piston ring into the deposition chamber of the HQ-2 RF-PECVD equipment, and the system is evacuated to 5×10 -3 Pa. Set the temperature to 300°C, turn on the heater, and start deposition when the temperature of the deposition chamber stabilizes at the set value. The selected radio frequency power is 150W, and the flow rates of silane and ammonia are respectively 45 sccm and 90 sccm by adjusting a mass flow meter (MFC). After the deposition time reaches 20 minutes, the reaction gas source, radio frequency source and heater are turned off, and the deposition is stopped. After the piston ring is cooled, it is taken out, and a uniform and dens...

Embodiment 2

[0021] The ordinary piston ring is polished with a DJP-II electrolytic polishing machine, the purpose is to improve the surface finish of the piston ring to be deposited and remove the oxide skin on the surface. Put the polished piston ring in an ultrasonic cleaner for 15 minutes, take it out and clean the surface with acetone. Then put the piston ring into the deposition chamber of the HQ-2 RF-PECVD equipment, and the system is evacuated to 5×10 -3 Pa. Set the temperature to 400°C, turn on the heater, and start deposition when the temperature of the deposition chamber stabilizes at the set value. The selected radio frequency power is 90W, and the flow rates of silane and ammonia are respectively 15 sccm and 60 sccm by adjusting a mass flow meter (MFC). After the deposition time reaches 30 minutes, the reaction gas source, radio frequency source and heater are turned off, and the deposition is stopped. After the piston ring is cooled, it is taken out, and a uniform and dense...

Embodiment 3

[0023] The ordinary piston ring is polished with a DJP-II electrolytic polishing machine, the purpose is to improve the surface finish of the piston ring to be deposited and remove the oxide skin on the surface. Put the polished piston ring in an ultrasonic cleaner for 15 minutes, take it out and clean the surface with acetone. Then put the piston ring into the deposition chamber of the HQ-2 RF-PECVD equipment, and the system is evacuated to 5×10 -3 Pa. Set the temperature to 500°C, turn on the heater, and start deposition when the temperature of the deposition chamber stabilizes at the set value. The selected radio frequency power is 120W, and the flow rates of silane and ammonia are respectively 30 sccm and 90 sccm by adjusting a mass flow meter (MFC). After the deposition time reaches 10 minutes, the reaction gas source, radio frequency source and heater are turned off, and the deposition is stopped. After the piston ring is cooled, it is taken out, and a uniform and dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com