Trip edge snow plow blade

A kind of edge and snow plow technology, applied in the direction of snow surface cleaning, construction, cleaning methods, etc., can solve the problems of snow plow blade damage, damage, invisible edge stones, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

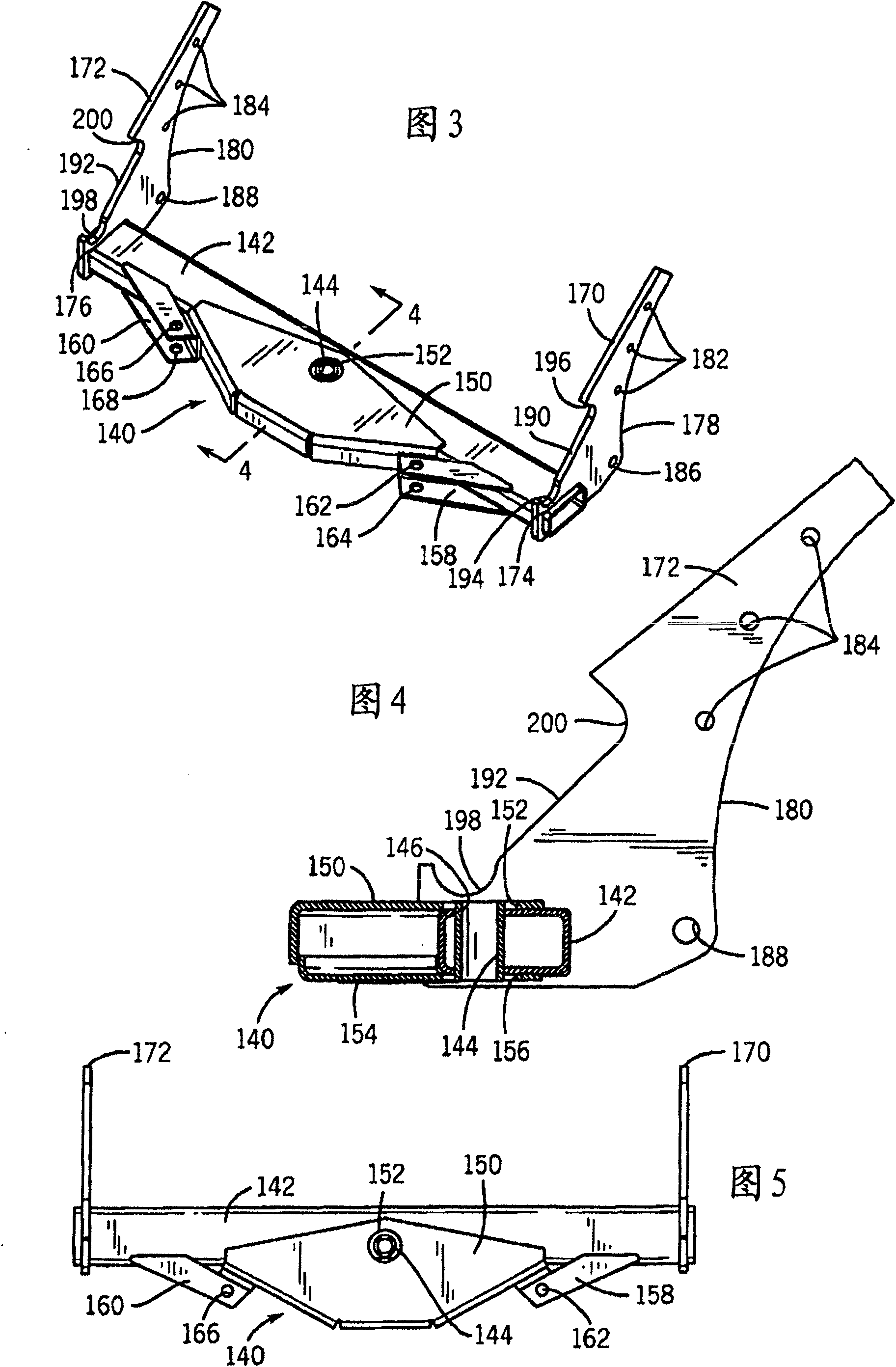

[0061] A preferred embodiment of the trip edge snow plow blade of the present invention is shown in a series of drawings in which the Figures 3 to 5 and 11 to 17 show some parts of an edge-engaging snowplough embodying the invention. Figures 18 to 26 An assembly of edge-engaging snow coulters embodying the invention is shown, Figure 27-29 The working method of the joint edge snow coulter of the present invention is shown. Figures 30 to 32 The assembled joint edge snow coulter of the present invention is shown.

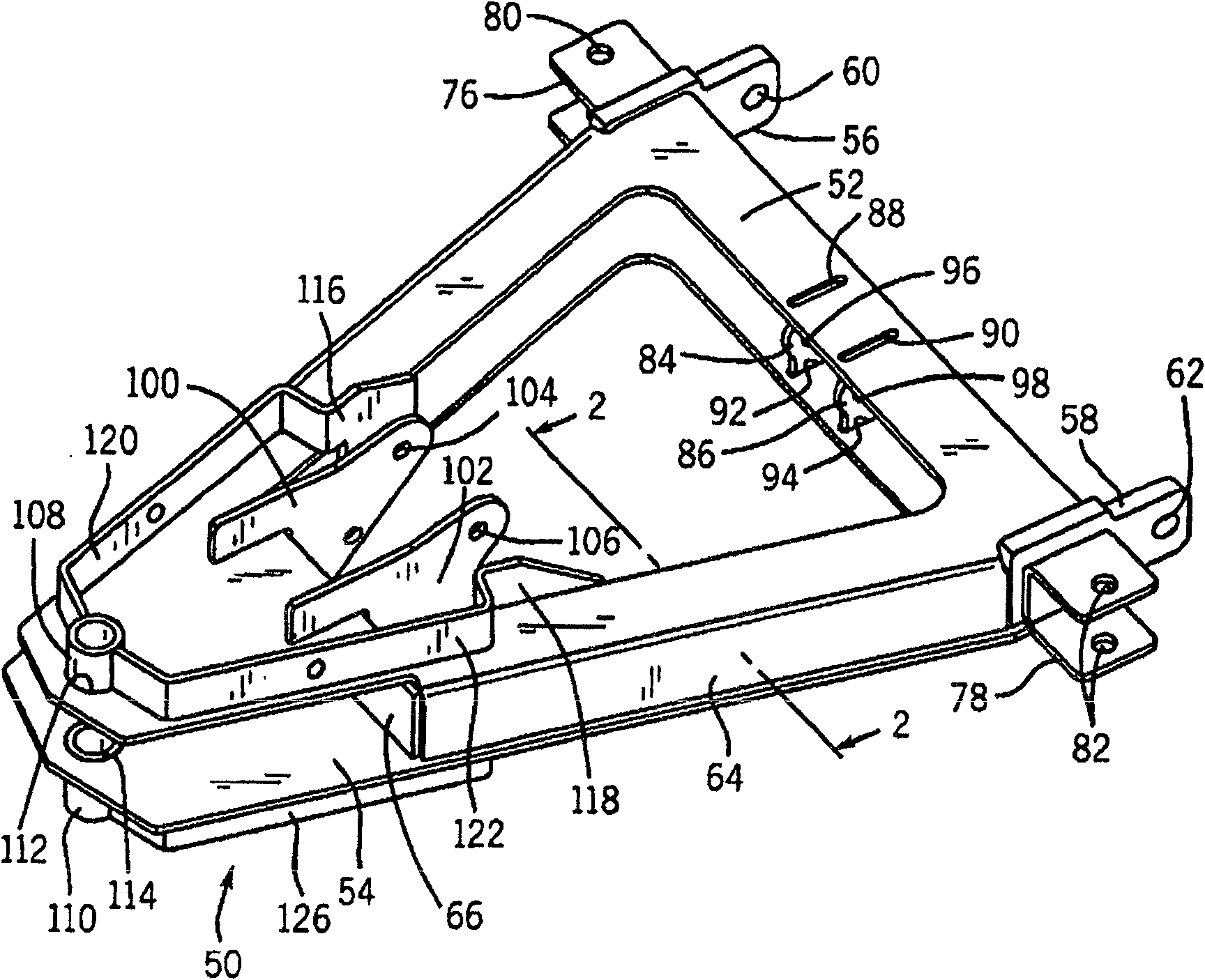

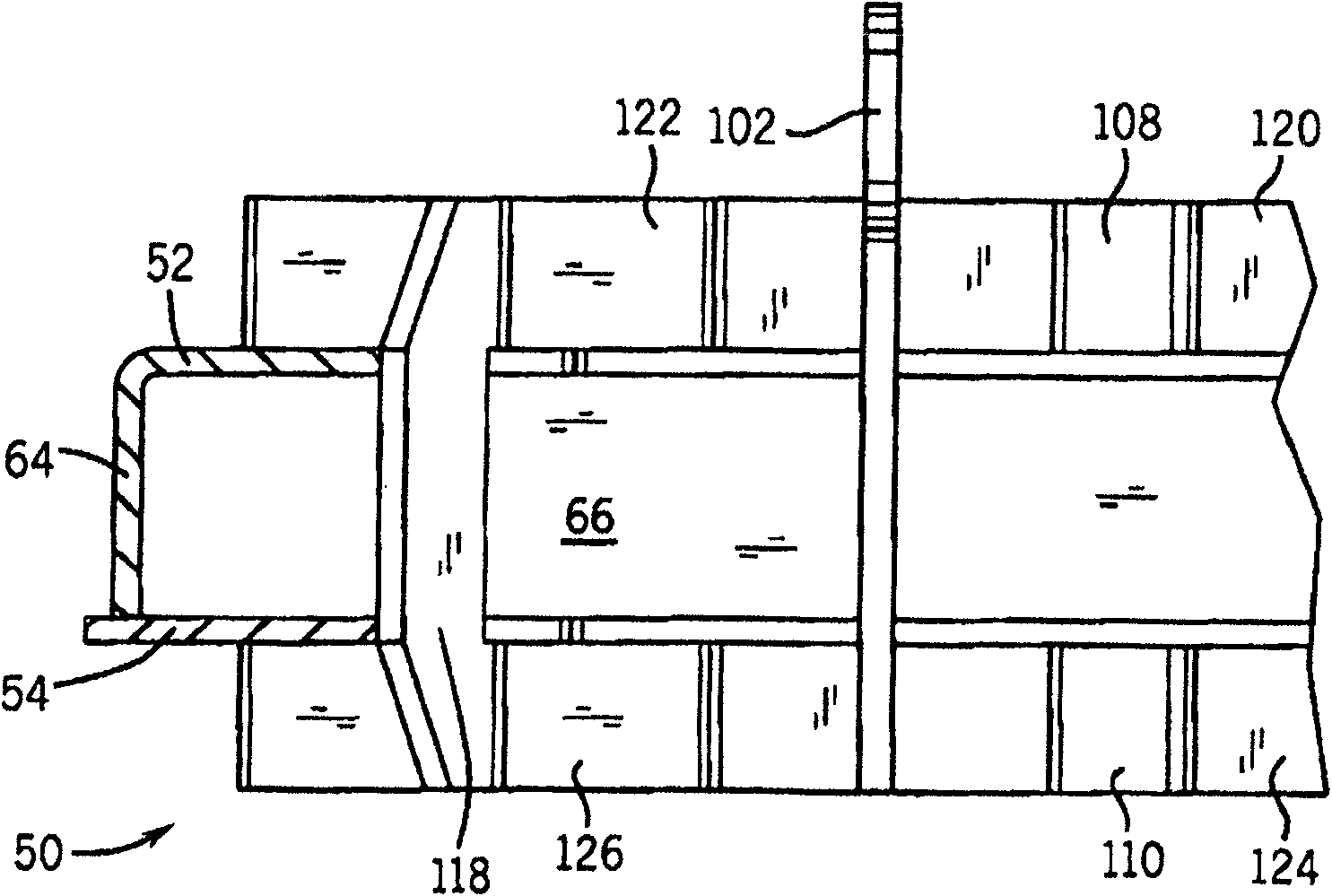

[0062] figure 1 , 2 , 6, 8 and 9 are parts of the snow plow frame on which the joint edge snow plow cutters of the present invention are mounted. Figure 7 is the hitch frame nose piece mounted on the truck to which the snow plow frame is mounted. Figure 10 Shown are the assembled parts of the snow plow frame and the installation of the snow plow frame on the hitch frame nose. Figure 33 The assembled joint edge snow plow cutter of the present invention is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com