Truncated platform composite material member and metal member positioning adhesion process

A composite material and frustum-shaped technology, which is applied in the direction of adhesives, connecting components, and bonding methods, can solve problems such as uneven thickness of the adhesive layer, waste, and misalignment of products, and achieve high axial positioning accuracy and ensure circumferential alignment. The effect of positioning and axial force uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

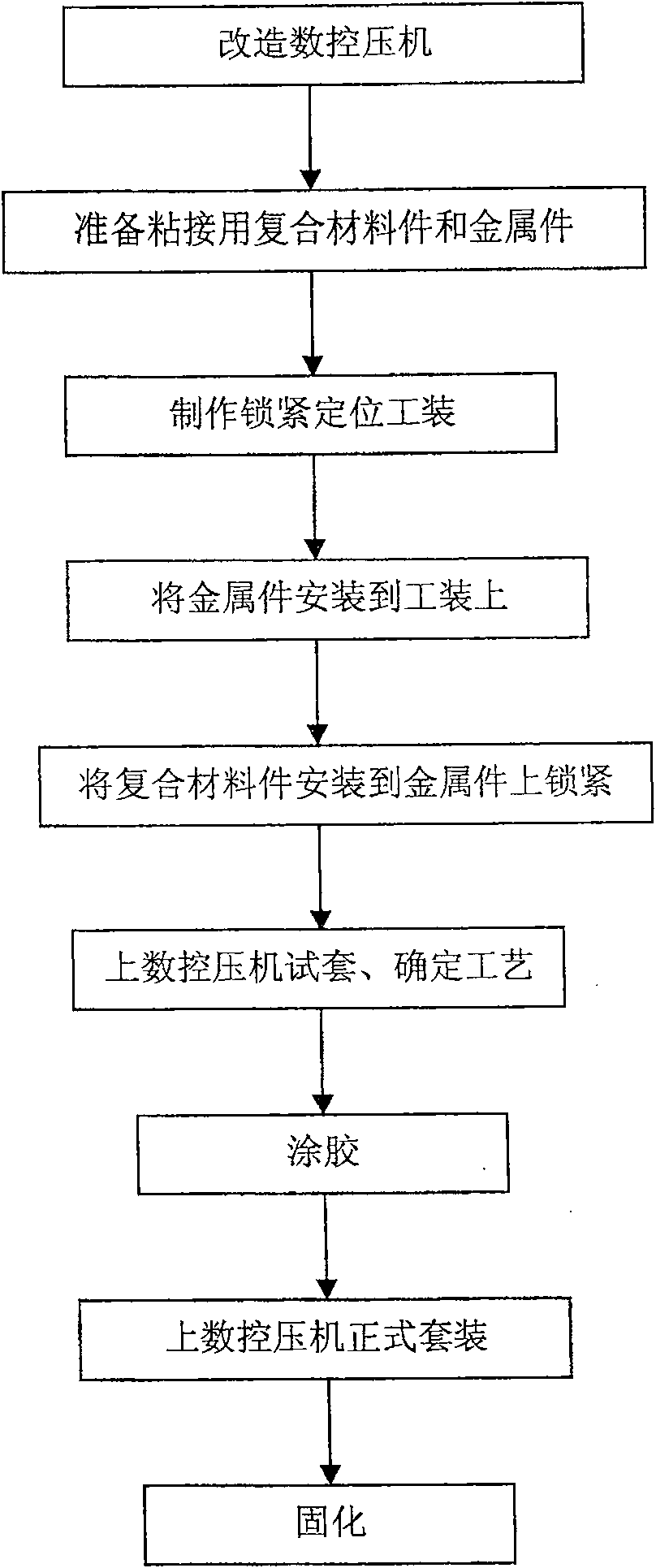

[0050] The flow chart of positioning bonding is as follows: figure 1 shown.

[0051] 1. Transformation of CNC press

[0052] Such as figure 2 The numerically controlled press shown includes a numerically controlled display screen 11, a base 12, a grating 13, a column 14, and a pressing plate 15. The numerically controlled display screen 11 is connected to the grating 13 through a data line, and the grating 13 is installed on the column 14. Above, the mechanical connection between the column 14 and the pressing plate 15 .

[0053] The numerical control display screen 11 can automatically display the set force and the displacement of the composite material parts, which could not be realized in the previous bonding process. The pressing plate 15 of the numerical control press is driven by a lead screw, and pressurized to apply force to the truncated circular composite material piece. The mechanical force is uniform, effective, and highly controllable, and is not affected by...

Embodiment 2

[0067] The parameters of the CNC press during the test set, σ is taken as 10Kn, and γ is taken as 0.4mm / min;

[0068] When the distance from the upper edge of the square protrusion of the frustum-shaped composite material piece to the bottom end of the frustum-shaped metal piece is 688.8 mm, the position of the frustum-shaped composite material piece is recorded by the grating 13 of the numerical control press. The gap between the frustum-shaped composite material part and the frustum-shaped metal part is 1.5mm, which exceeds the specified 0.8mm. After wrapping 4 layers of glass cloth tape on the outer surface of the frustum-shaped metal part, squeeze out the excess gap space.

[0069] The glue thickness is 0.35mm.

[0070] According to the formula σ=η·γ, determine the parameters of the CNC press in the formal suit. γ is 0.18mm / min, and σ is 20Kn. Input the determined σ and γ into the CNC press, and start the formal suit. When the CNC press presses the platen The CNC press st...

Embodiment 3

[0074] For the parameters of the CNC press during the test set, σ is taken as 15Kn, and γ is taken as 0.5mm / min;

[0075] When the distance from the upper edge of the square protrusion of the frustum-shaped composite material piece to the bottom end of the frustum-shaped metal piece is 688.2 mm, the position of the frustum-shaped composite material piece is recorded by the grating 13 of the numerical control press. The gap between the frustum-shaped composite material part and the frustum-shaped metal part is 1.6mm, which exceeds the specified 0.8mm. After wrapping 4 layers of glass cloth tape on the outer surface of the frustum-shaped metal part, the excess gap space is squeezed out.

[0076] The glue thickness is 0.4mm.

[0077] According to the formula σ=η·γ, determine the parameters of the CNC press during the formal assembly. γ is 0.2mm / min, and σ is 22Kn. Input the determined σ and γ into the CNC press to start the formal assembly. When the CNC press presses the platen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com