Belt type conveyor dynamics parameter calculation method

A technology of belt conveying and calculation method, applied in calculation, electrical digital data processing, special data processing application, etc., can solve the problems of high power of driving motor, inaccurate calculation of running resistance of conveyor, and high investment cost of conveyor belt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

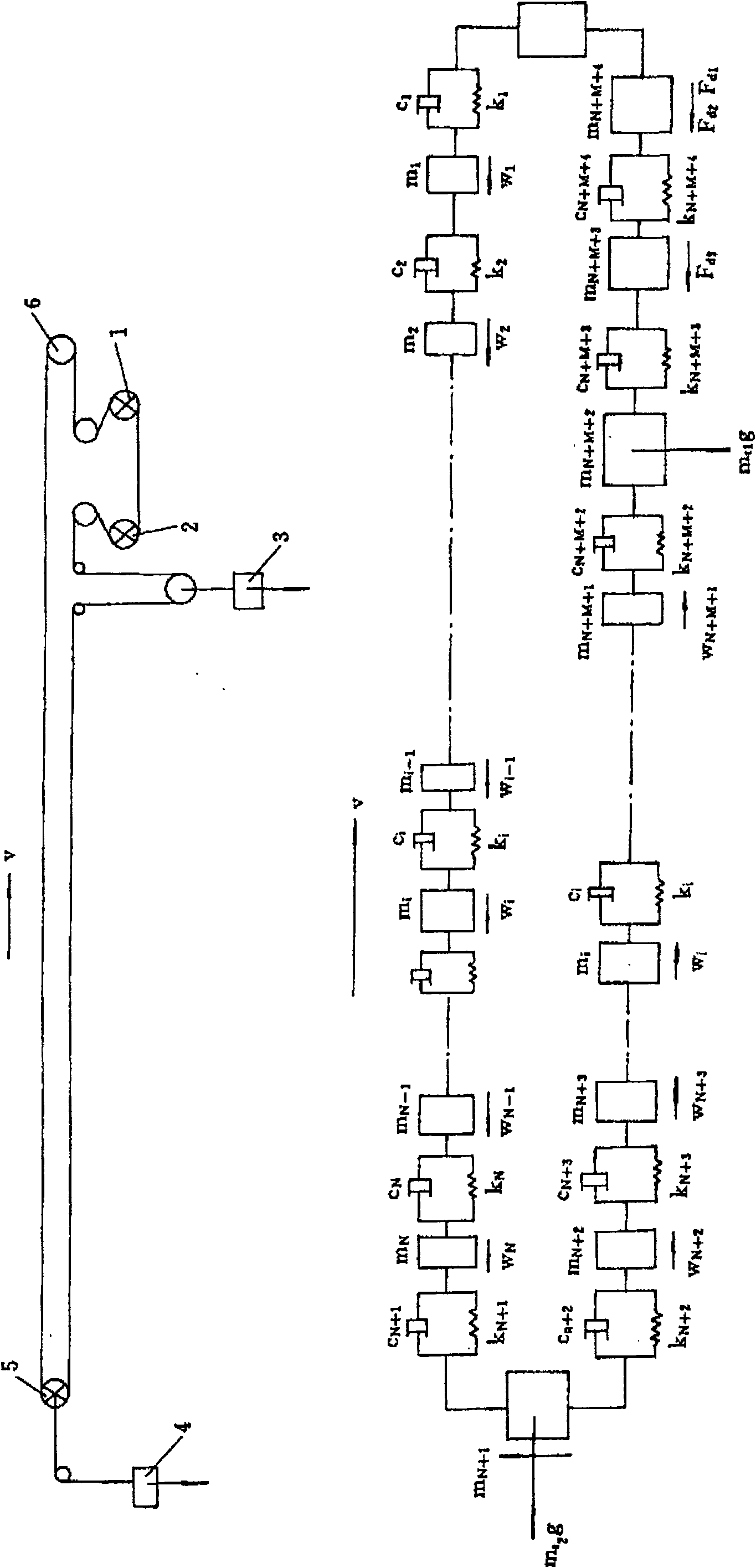

[0319] The calculation process of the inventive method is carried out with the following steps:

[0320] 2.1 Unit number

[0321] Numbering principle:

[0322] The head roller is the last unit, and each conveyor belt section is two adjacent rollers. The number of units in this section is Num(i), and the number of sections is the same as the number of rollers, that is, NPul sections;

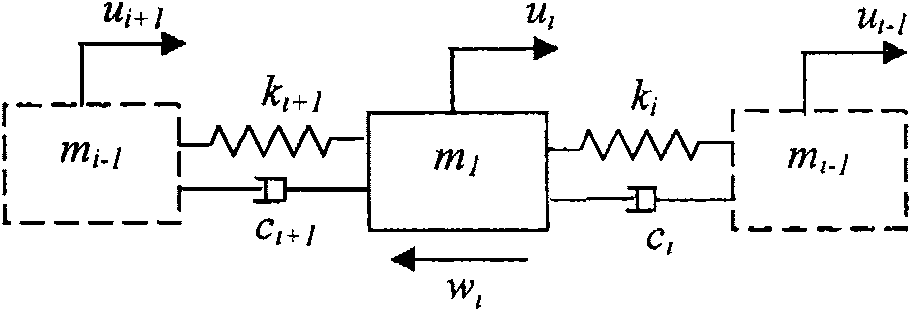

[0323] The roller is one degree of freedom; the tensioning device (automatic or heavy hammer) is two degrees of freedom;

[0324] Total units: Nelement = Σ i = 1 NPul Num ( i ) + NPul + Ntake - - - ( 2 - 1 )

[0325] NPul - the number of rollers;

[0326] NTake - tension num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com