Discharge device of injection moulding machine in two-stage type

An injection molding machine, two-stage technology, applied in the discharge device field of the residual plastic of the two-stage injection molding machine, can solve the problems of polluting the quality of the finished product, polluting the finished product, unable to rotate, etc., and prolong the service life , Avoid the effect of deteriorating plastics from polluting the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

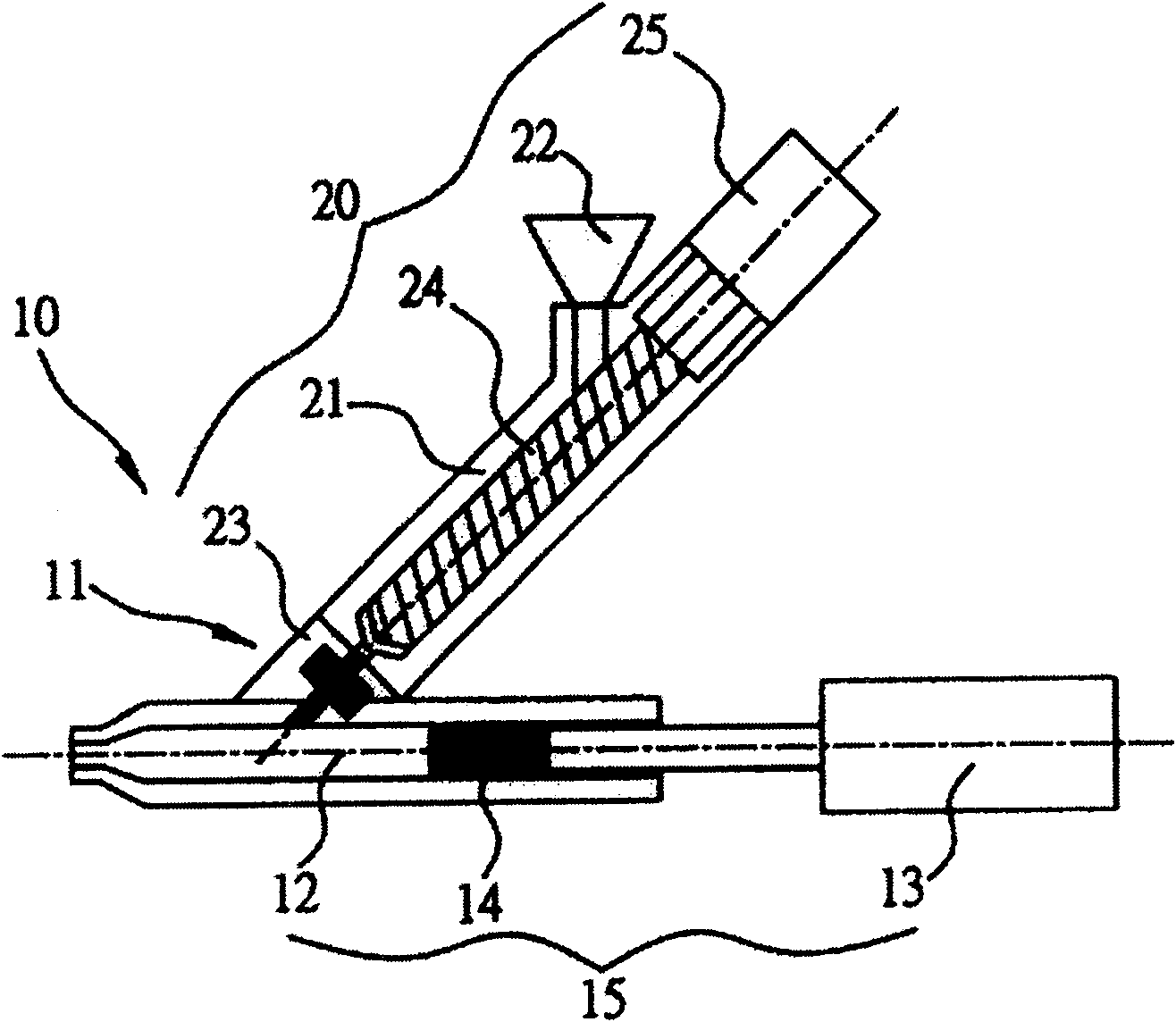

[0028] Figure 1A , Figure 1B This is embodiment 1 of the discharge device 11 of the two-stage injection molding machine 10 disclosed in the present invention, wherein the two-stage injection molding machine 10 is as Figure 1A , It includes an injection part 15 with an injection tube 12, a driving unit 13 and an injection rod 14, and a feeding part 20 obliquely arranged on the injection part 15 at an angle, and the feeding part 20 feeds the In the injection tube 12 of the injection part 15, the injection rod 14 is pushed by the driving unit 13, such as a driver, to perform plastic injection and complete injection molding; at the same time, the metering feeding part 20 is as shown in the figure, including materials Tube 21, hopper 22, check unit 23 (check shaft seat), feed screw 24, and feed drive motor 25. The feed drive motor 25 drives the feed screw 24 for feeding measurement. In addition, Other feeding parts that can achieve the same melt metering effect can also be used, s...

Embodiment 2

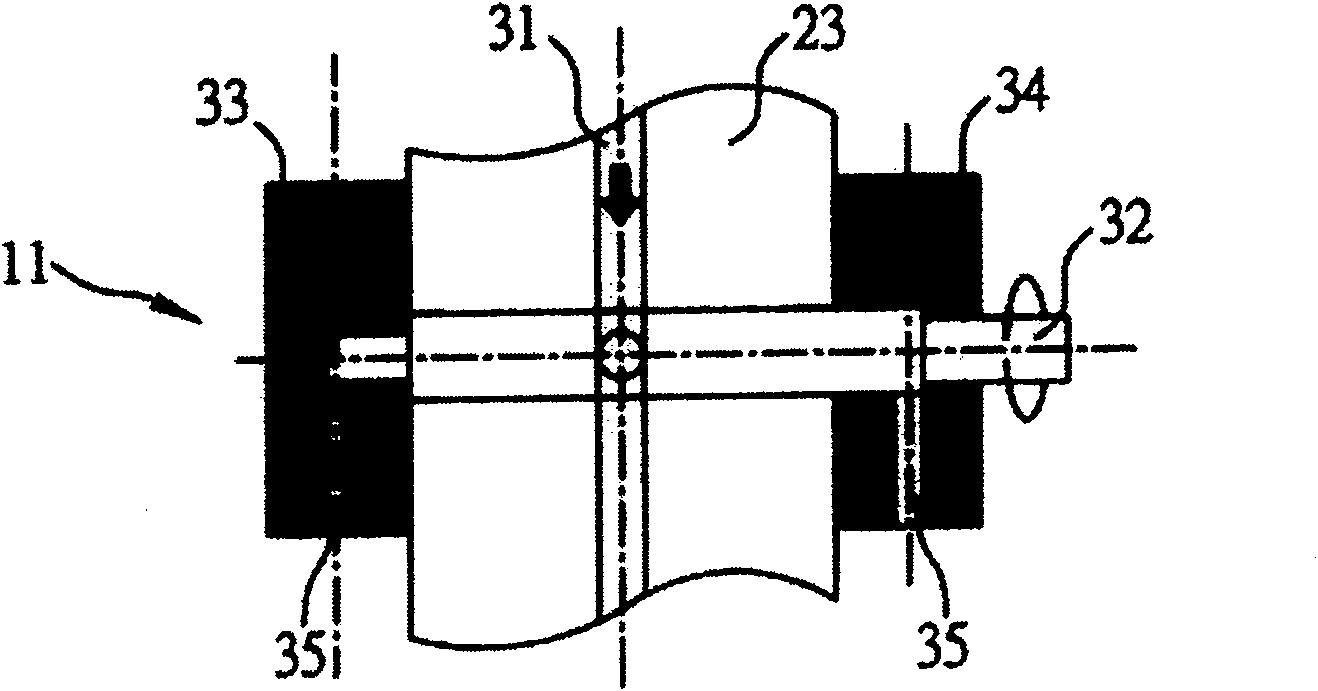

[0033] In addition to the content described in the above embodiment 1, the present invention can also be provided with an adjustable unit in the discharge holes 35 on the cover plates 33, 34 to adjust the discharge speed of the residual plastic according to the characteristics of different plastics; Therefore, with the adjustable unit, the non-return shaft 32 does not need to be replaced when the plastic is changed. It is only necessary to adjust the adjustable unit to change the flow rate of the residual plastic according to the fluidity of the changed plastic.

[0034] figure 2 It is the second embodiment of the present invention. It is provided with an adjusting bolt 41 in the first and second cover plates 33 and 34 respectively, and the adjusting bolt 41 is used to adjust the size of the discharge hole 35, thereby adjusting the residual plastic Discharge speed; therefore, when feeding or stopping feeding, the size of the discharging hole 35 can be adjusted according to the ch...

Embodiment 3

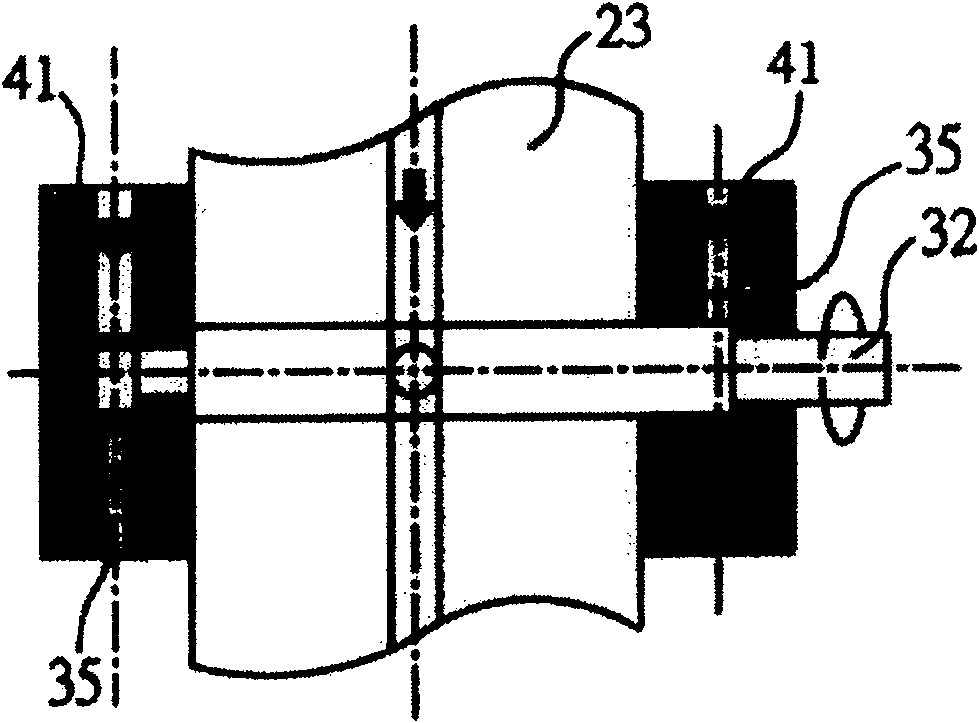

[0036] image 3 This is the third embodiment of the present invention, which is to modify the design of the adjustable unit, where the adjustable unit is a combination of the adjusting bolt 42, the adjusting spring 43 and the anti-leak block 44 for feeding or stopping When using the adjusting bolt 42 to adjust the pressure applied to the discharge hole 35 by the spring 43 and the anti-leak block 44 according to different plastic characteristics to determine the degree of leakage, thereby preventing the non-return shaft 32 from jamming and residual plastic burnt Disadvantages of cracking and polluting the melt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com