Voltage check device for gas insulation apparatus

A technology of gas-insulated equipment and voltage detection, applied in the direction of measuring devices, switchgears, switchgear settings, etc., can solve problems such as overvoltage insulation, damage, and voltage increase, so as to avoid insulation damage, prevent overvoltage, reduce The effect of sharing the voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

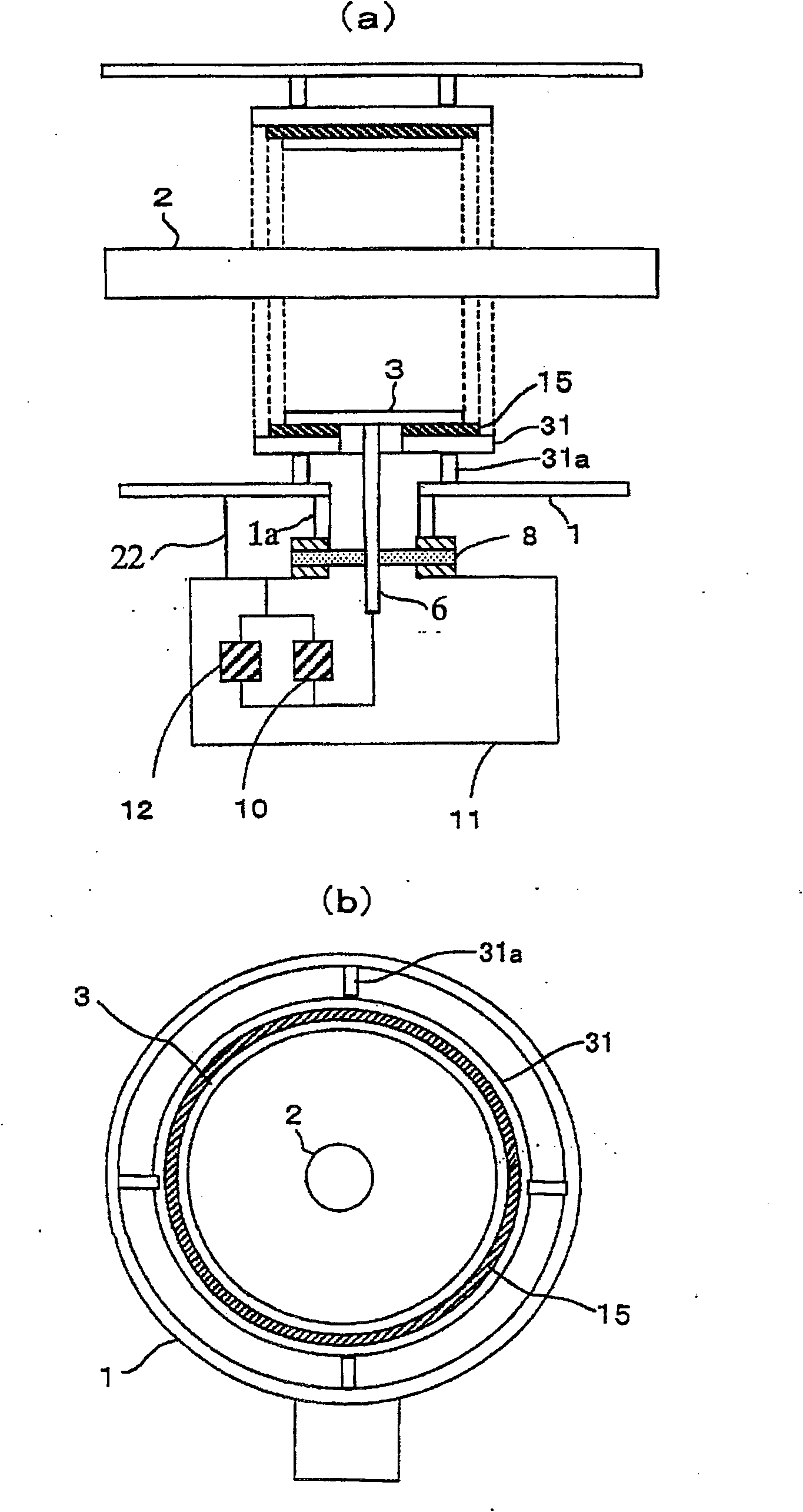

[0061] In addition, in the above-mentioned first embodiment, the annular insulating layer 15 as the insulating supporting member is arranged in contact with the outer circumference of the intermediate electrode 3, but it may be as follows: Figure 9 , Figure 10 As shown, a supporting member for supporting the intermediate electrode 3 on the inner surface of the grounded metal container 1 is constituted. Figure 9 and Figure 10 It is a side cross-sectional view and a cross-sectional view showing the structure of a support member that supports the intermediate electrode 3 on the inner surface of the grounded metal container 1 according to Embodiment 2 of the present invention. In addition, the structure other than the support member shown in a drawing is the same as that of Embodiment 1 mentioned above.

[0062] Such as Figure 9 , Figure 10 As shown, the container-side annular support conductor 26a as the first annular support conductor, and the intermediate electrode-si...

Embodiment approach 3

[0067] Figure 11 It is a partial cross-sectional view showing the configuration of the voltage detection device of the gas insulated equipment according to the third embodiment, Figure 11 (a) represents a side sectional view, Figure 11 (b) means Figure 11 Cross-sectional view of line XI(b)-XI(b) in (a).

[0068] in addition, Figure 11 For the convenience of expression, only the low-voltage side of the intermediate electrode 3 is shown, and the illustration inside the outer box 11 is omitted, but the omitted parts are all related to figure 1 The above-mentioned Embodiment 1 shown above is the same.

[0069] As shown in the figure, the intermediate electrode 3 is supported on the inner surface of the grounded metal container 1 by an insulating support member 5 . The insulating support member 5 here is the same support as a conventional member. The connecting conductor 6 for extracting voltage is installed on the intermediate electrode 3, and the connecting conductor 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com