Rust conversion and rust-proof coating agent for construction steel structure and its usage method

A technology for steel structure and construction, applied in the field of anti-rust coating agent, can solve the problems of low internal quality of paint, slow construction progress, incomplete rust removal, etc., achieve clean and thorough rust removal, avoid sewage discharge, and protect Effects of working environment and natural environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

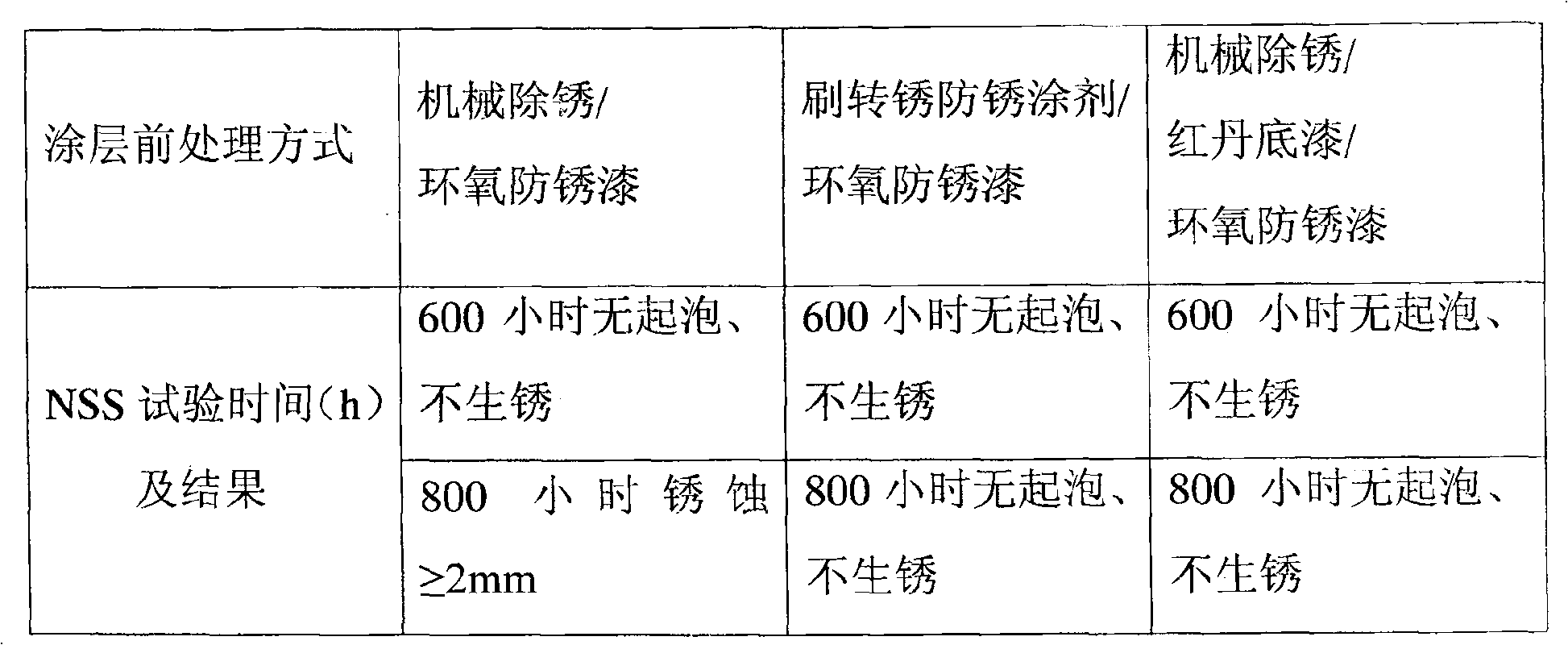

Examples

Embodiment 1

[0041] Choose from the same amount of C 6 h 2 (OH) 3 COOH·H 2 O and C 76 h 52 o 46 Composed of 500g of multi-acid rust converting agent, 20g of gelling agent, 1g of atmospheric corrosion inhibitor, 0.5g of penetrating agent, 0.5g of silicone defoamer, and water as the balance, add them to the reaction tank in turn, and mix at 40°C Stir for 48 minutes, cool and filter to obtain 1 L of finished product of yellow liquid rust-reversing anti-rust coating agent for steel structure.

Embodiment 2

[0043] Choose C with a mass ratio of 3:1 6 h 2 (OH) 3 COOH·H 2 O and C 6 h 8 o 7 ·H 2 600g of multi-acid rust-converting agent composed of O, 30g of gelling agent, 1.5g of atmospheric corrosion inhibitor, 0.6g of penetrant, 0.4g of silicone defoamer, and water as the balance, are added to the reaction tank in sequence, and heated at 40°C Mix and stir at lower temperature for 50 minutes, cool and filter to obtain 1L finished product of steel structure rust-reversing and anti-rust coating agent in colorless liquid state.

Embodiment 3

[0045] Select H with a mass ratio of 3:1 3 PO 4 and C 6 h 8 o 7 ·H 2 400g of multi-acid rust-converting agent composed of O, 25g of gelling agent, 2g of atmospheric corrosion inhibitor, 0.9g of penetrant, 0.1g of silicone defoamer, and water as the balance, are added to the reaction tank in sequence, and heated at a temperature of 40°C Mix and stir for 51 minutes, cool and filter to obtain 1 L of finished product of steel structure rust-reversing and antirust coating agent in colorless liquid state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com