Novel sharpener

A knife sharpener, a new technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of difficult operation and high work intensity, and achieve the effect of convenient replacement, simple structure, and convenient and quick sharpening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

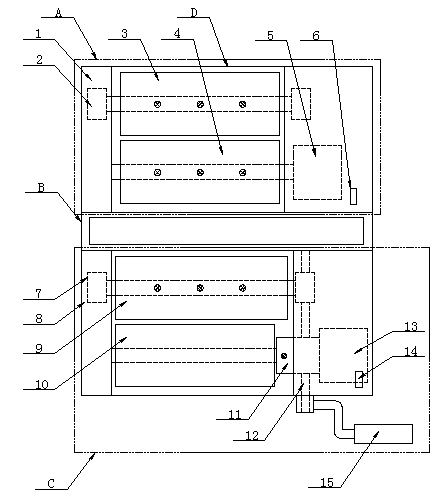

[0014] refer to figure 1 , the specific embodiment adopts the following technical scheme: it includes derusting area A, cleaning area B, sharpening area C and base D, the middle part of the upper end of base D is provided with cleaning area B, and both sides of cleaning area B are respectively provided with derusting areas A and sharpening area C.

[0015] The derusting area A includes the first overturning seat 1, the positioning block 2, the first derusting grinding wheel 3, the second derusting grinding wheel 4, the derusting motor 5 and the derusting switch 6, and the first overturning base 1 is vertically arranged on On the upper part of one side of the base D, the first derusting grinding wheel 3 and the second derusting grinding wheel 4 are arranged in parallel between the first turning seat 1 and the base D. The turning seat 1 is connected to the base D, and one end of the second derusting grinding wheel 4 is connected to the derusting motor 5 inside the base D, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com