Real time dual bus control method for warp knitting machine

A control method and warp knitting machine technology, applied in bus network, warp knitting, comprehensive factory control, etc., can solve the problems of low manufacturing cost, affecting the control of the whole machine, unable to realize real-time control of high-speed warp knitting machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

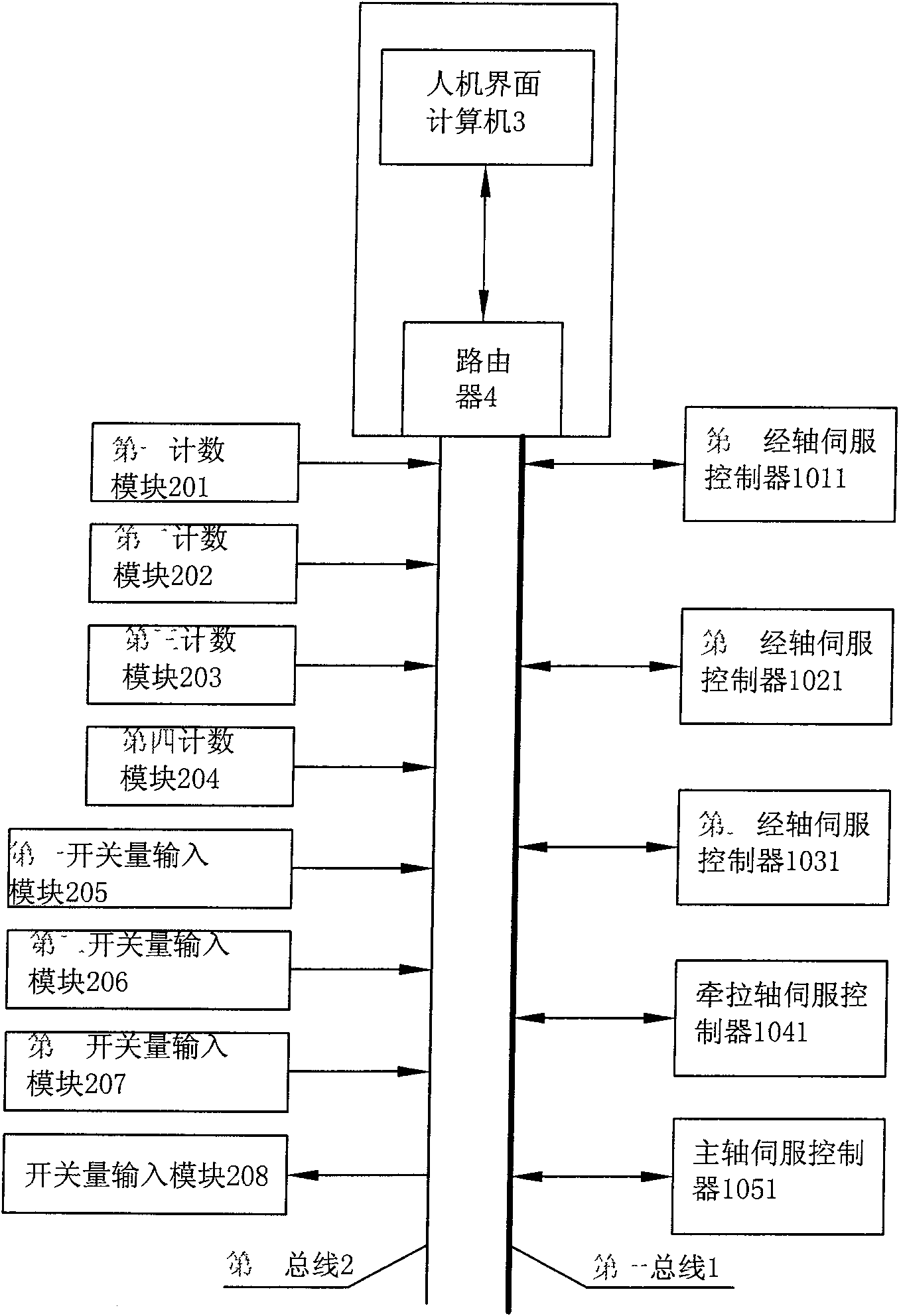

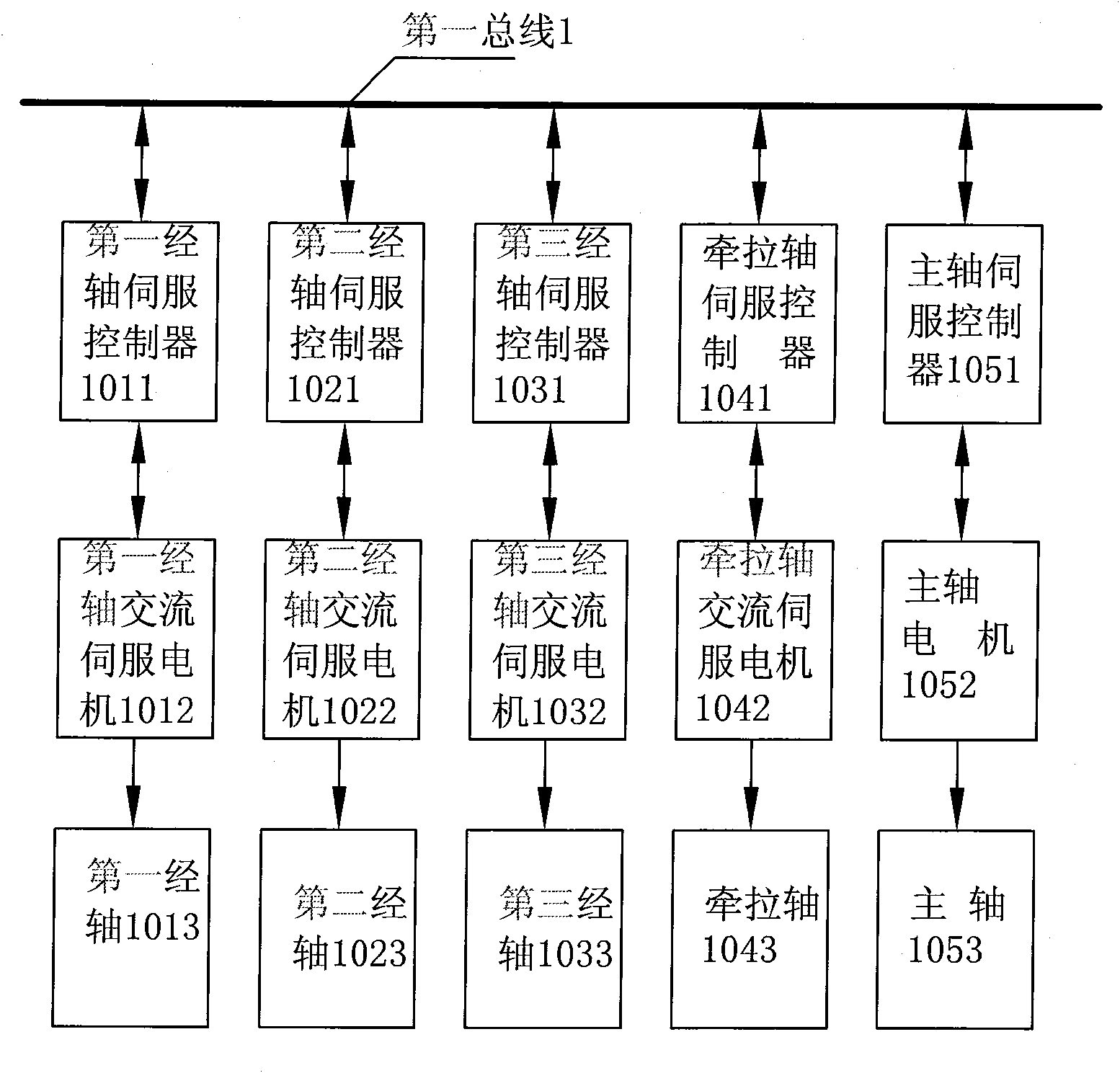

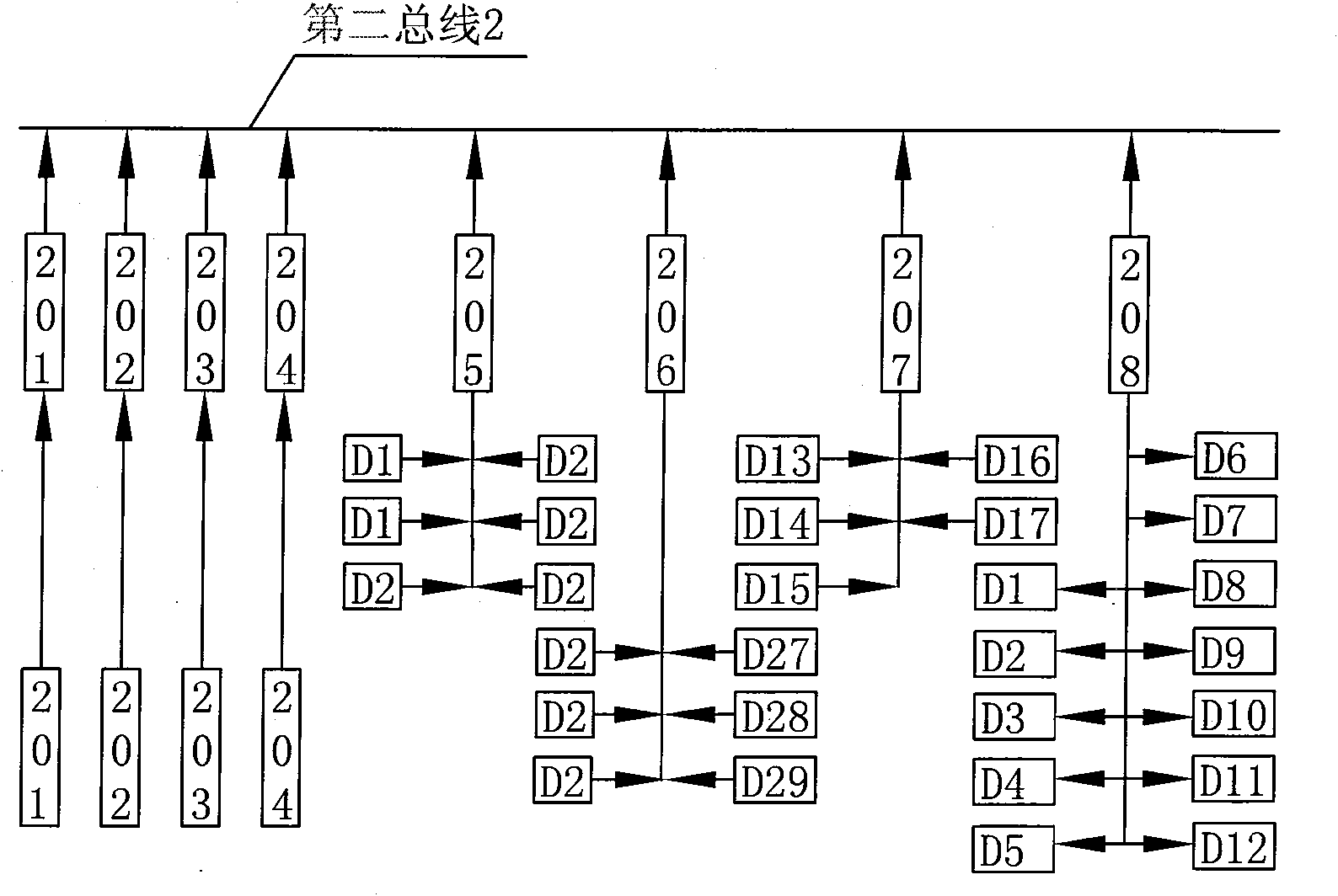

[0016] see figure 1 , a real-time dual-bus control method for a warp knitting machine of the present invention is a method for controlling a warp knitting machine using a network and a computer. It uses two buses, the first bus 1 and the second bus 2, and the first bus 1 uses High-speed real-time bus to control the operation of the first warp beam 1013, the second warp beam 1023 and the third warp beam 1033, a pulling shaft 1043 and a main shaft 1053, the first warp beam 1013, the second warp beam 1023 and the third warp beam 1033 three warp beams respectively by the first warp beam servo controller 1011, the second warp beam servo controller 1021, the third warp beam servo controller 1031 and the first warp beam AC servo motor 1012, the first warp beam The second warp beam AC servo motor 1022 and the third warp beam AC servo motor 1032 are driven, and the warp knitting instructions are transmitted to the corresponding first warp beam servo controller 1011, the second warp bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com