Linear motor

一种线性电动机、线圈的技术,应用在电动组件、电气元件、机电装置等方向,能够解决速度不均、难冷却、复杂冷却构造等问题,达到利用效率高、机械强度强、简单构造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

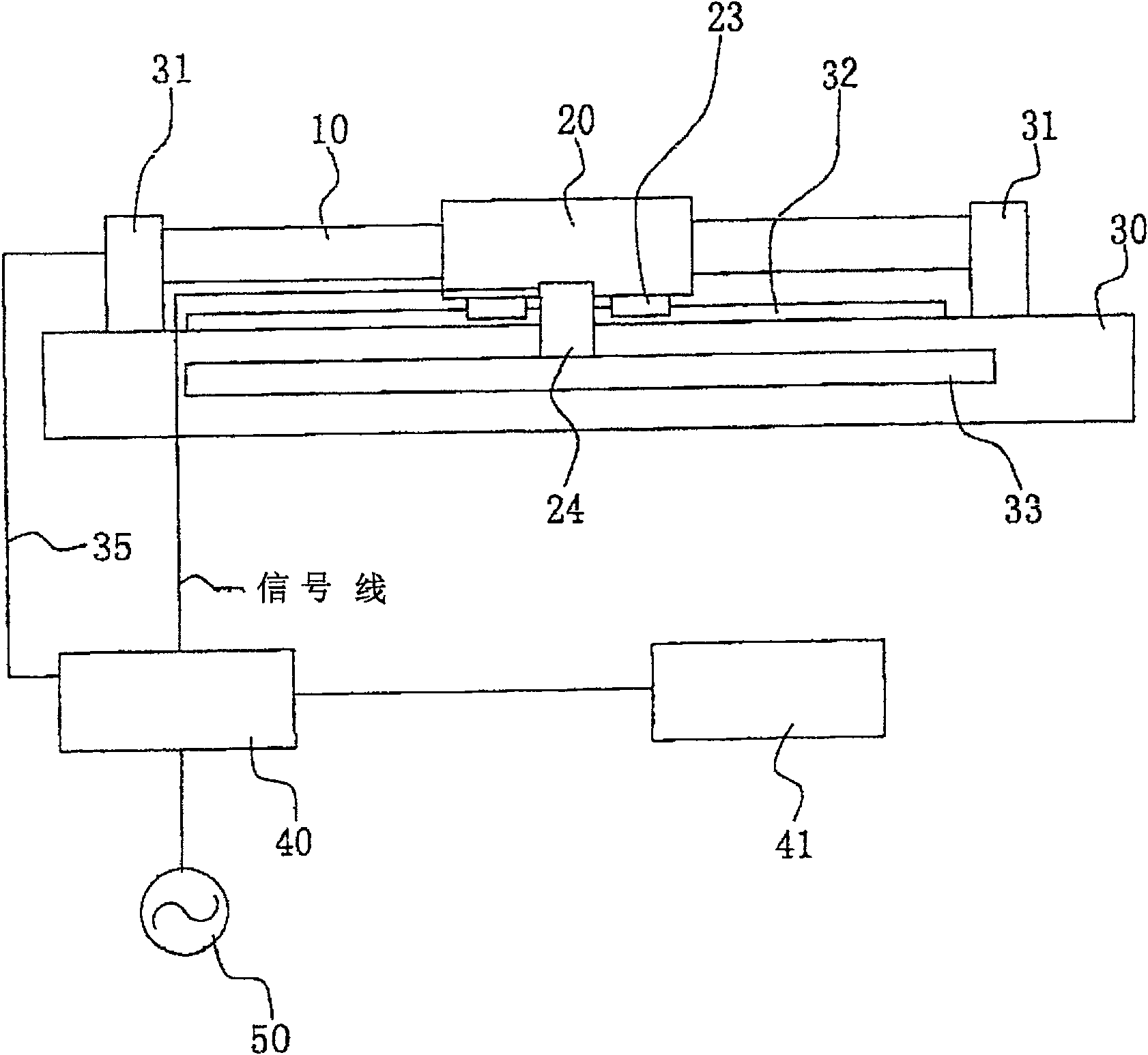

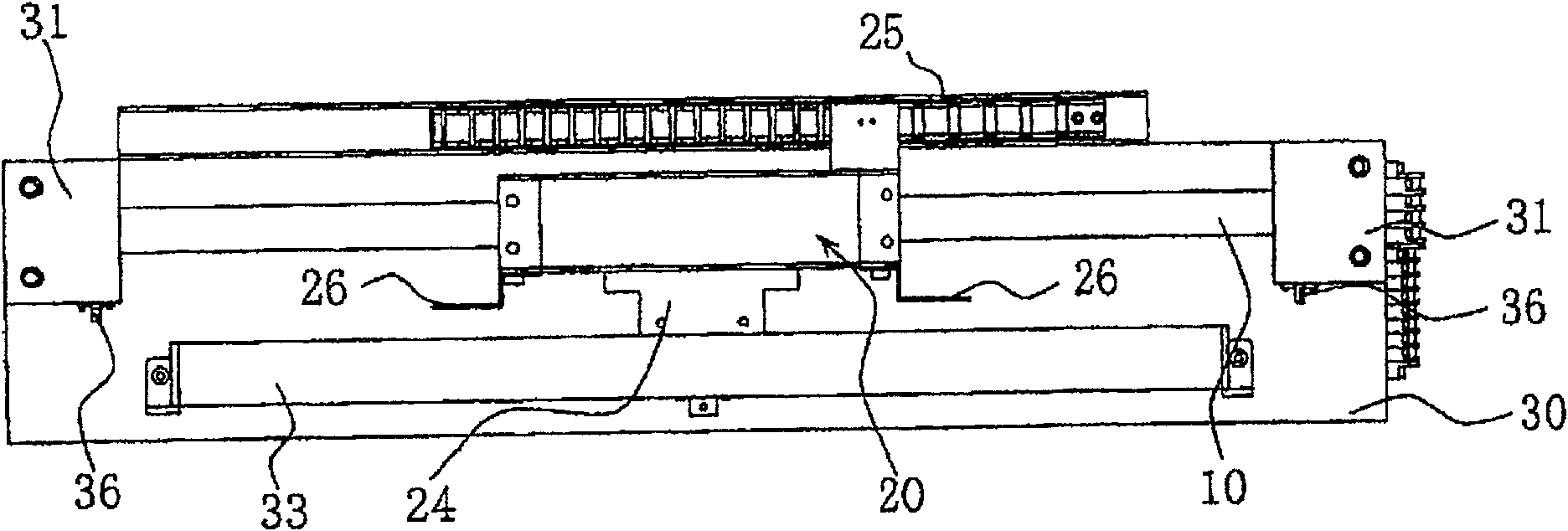

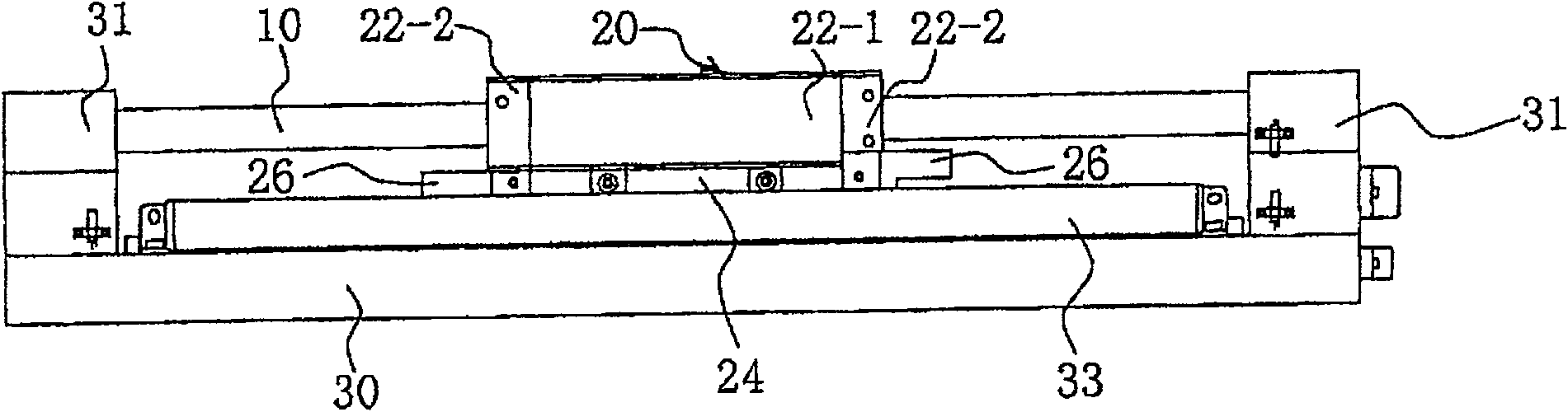

[0097] Hereinafter, a linear motor according to a first embodiment of the present invention will be described. figure 1 shows the schematic composition of a linear motor, Figure 2a to Figure 2d This is a diagram of a linear motor viewed from four directions. which is Figure 2a for the floor plan, Figure 2b for from Figure 2a The side view seen from the underside, Figure 2c for from Figure 2a The side view seen from the upper side, Figure 2d for from Figure 2a Figure seen on the right.

[0098] figure 1 , Figure 2a to Figure 2d Among them, the linear motor includes: a shaft body (hereinafter referred to as a stator) 10 that accommodates a plurality of continuously arranged electromagnet coils (hereinafter referred to as coils); A movable magnet (hereinafter referred to as a mover) 20 that can move in the same direction as the extending direction of 10 . The stator 10 is spanned between two brackets 31 fixed to the base 30 with a certain interval therebetwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com