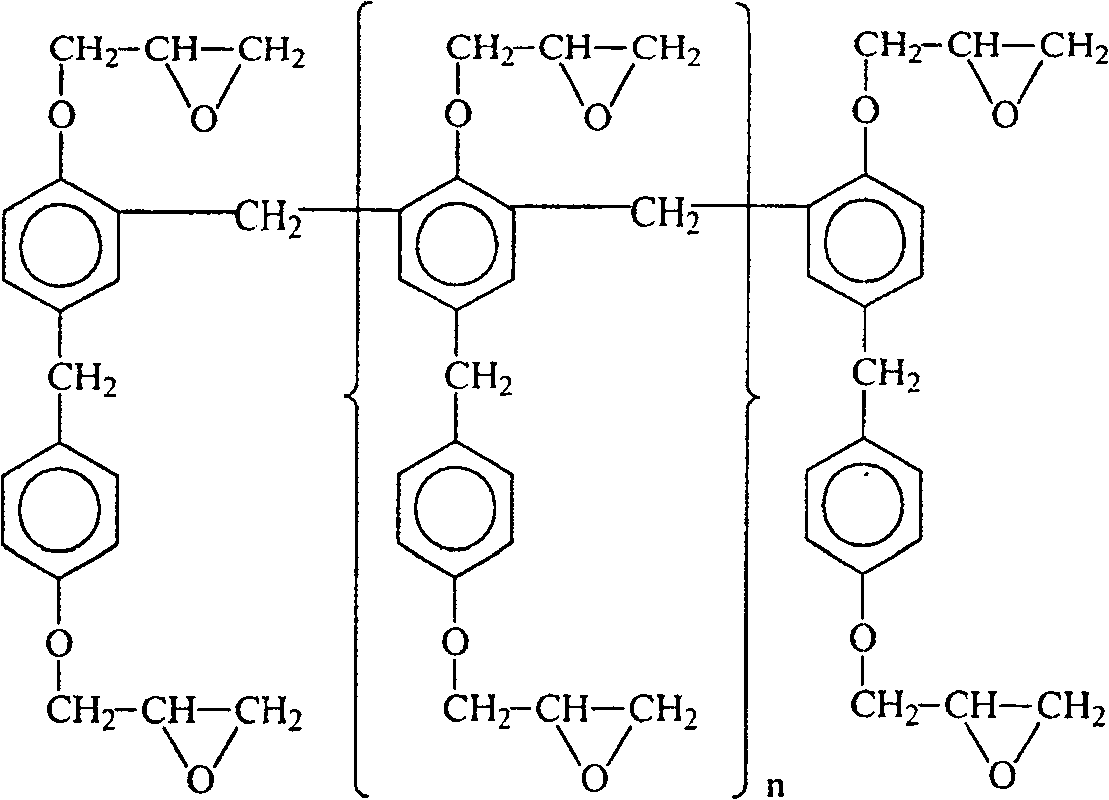

Linetype bisphenol F phenolic epoxy resin and preparation method thereof

A technology of novolac epoxy resin and phenolic resin, which is applied in the field of online bisphenol F novolac epoxy resin and its preparation, can solve the problems of low crosslinking density, reduced impact resistance, and large molecular chain rigidity of the product, and achieve the goal of preparing The method is reliable and easy to implement, the effect of impact resistance is improved, and the crosslinking density is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Components: novolac bisphenol F phenolic resin (softening point: 58° C.): 200 g, epichlorohydrin: 900 g, benzyltrimethylammonium chloride: 3 g, NaOH solution (50%): 164 g, toluene: 470 g.

[0031] Preparation method: Add the raw materials novolac bisphenol F phenolic resin and epichlorohydrin into a 2000ml three-necked flask according to the ratio, start stirring to completely dissolve the novolac bisphenol F phenolic resin, then add benzyltrimethylammonium chloride and stir Evenly, then raise the temperature to 100°C for 2 hours, then control the reaction temperature at 80°C, add 123g NaOH solution dropwise at a constant speed for 2 hours, keep the temperature for 1 hour after the dropwise addition, and then use filter cloth to filter out the salt generated by the reaction , take off epichlorohydrin under reduced pressure, obtain thick linear bisphenol F novolac epoxy resin, then add 150g toluene in the there-necked flask, stir and dissolve thick linear bisphenol F novo...

Embodiment 2

[0038] Components: novolac bisphenol F phenolic resin (softening point 106°C): 200g, epichlorohydrin: 1100g, tetramethylammonium chloride: 1.6g, NaOH solution (50%): 188g, NaOH solution (10% ): 20g, butanone: 400g.

[0039] Preparation method: Add the raw materials novolac bisphenol F phenolic resin and epichlorohydrin into a 2000mi three-necked flask according to the ratio, start stirring to completely dissolve the novolac bisphenol F phenolic resin, then add tetramethylammonium chloride and stir evenly, Then the temperature was raised to 65° C. for 3 hours, and then, 188g NaOH solution (concentration was 50%) was added dropwise at a constant speed with a constant pressure dropping funnel, while the there-necked flask was controlled to be negative pressure (pressure controlled by dropping lye speed and The same rate of detached liquid shall prevail), add epichlorohydrin every 0.5 hours (the additional amount should be equal to the detached amount), and the dripping time is 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com