SMT no-lead tinol

A lead-free solder paste and solder paste technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as incomprehension of welding performance, and achieve low corrosiveness, light color, and high insulation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

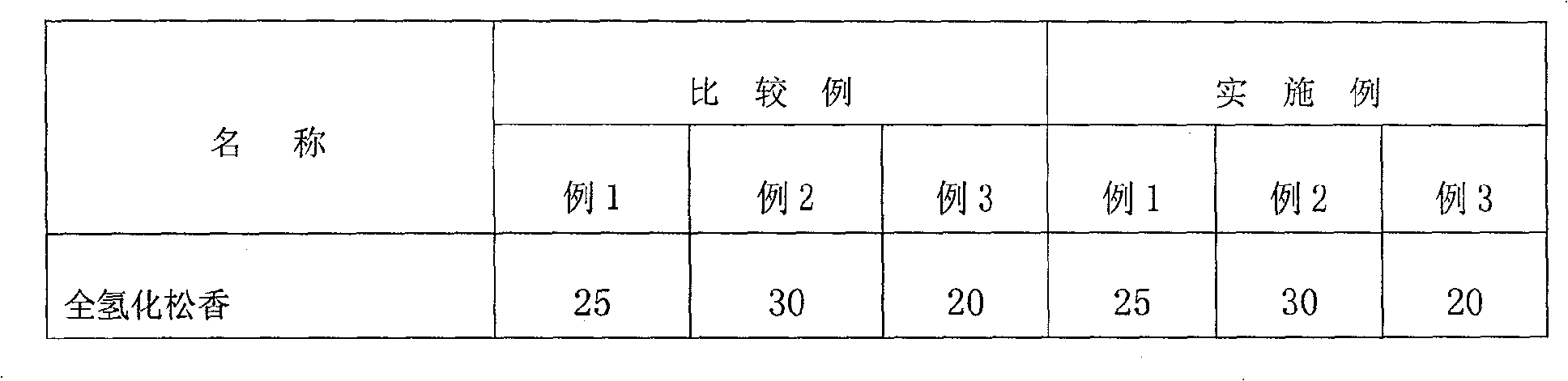

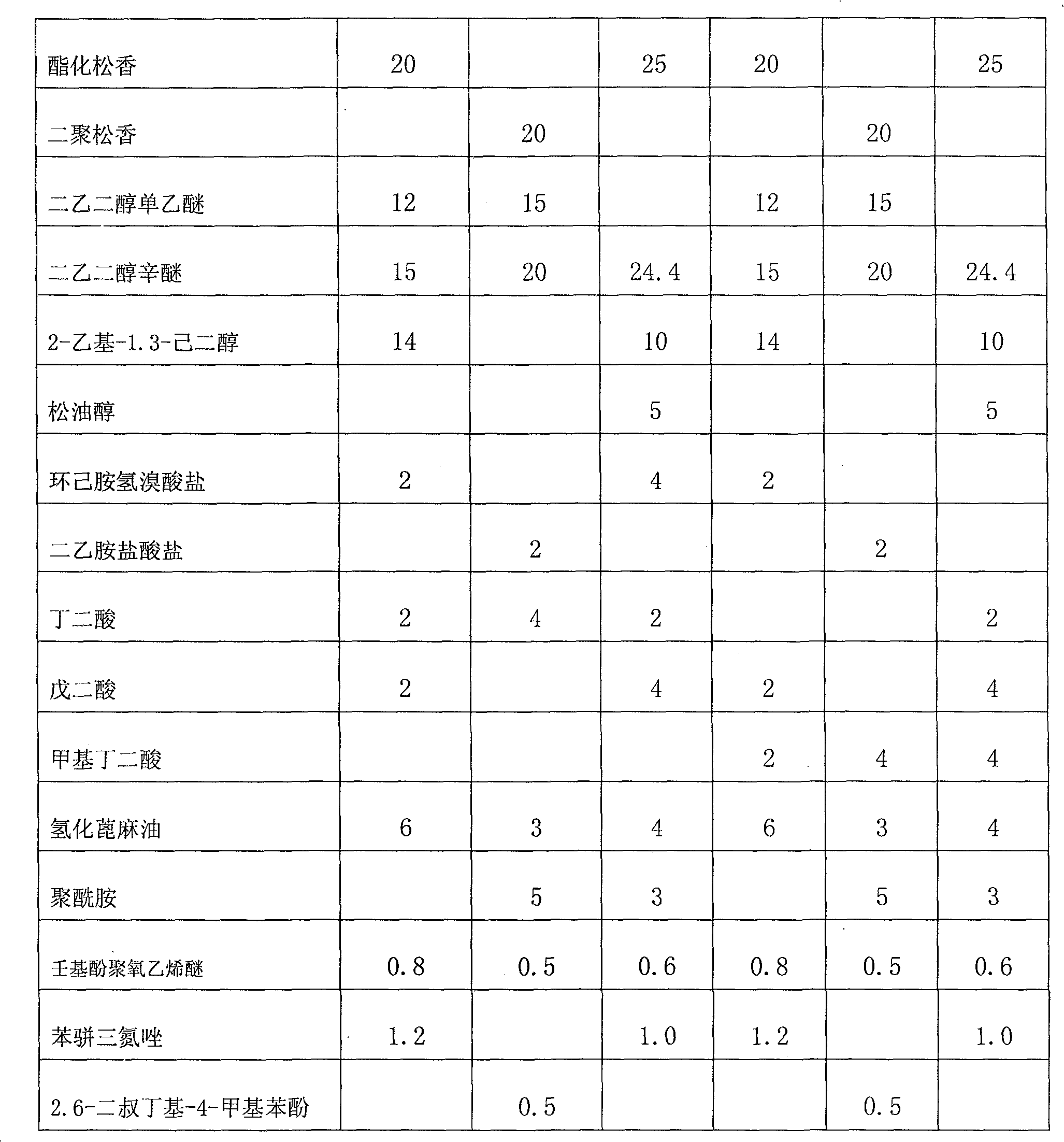

[0013] The invention provides a solder paste for surface mount technology lead-free solder paste, wherein the solder paste includes a solvent, a thixotropic agent, an adhesive, a composite active agent, a surfactant and an antioxidant, and the composite active agent is composed of The composite active agent that methyl succinic acid and other organic acids, halogen salts forms, and described halogen salts is diphenylguanidine hydrobromide or diphenylguanidine hydrochloride, the following is the formula of solder paste of the present invention Examples and comparative examples. See Table 1:

[0014]

[0015]

[0016] Table 1

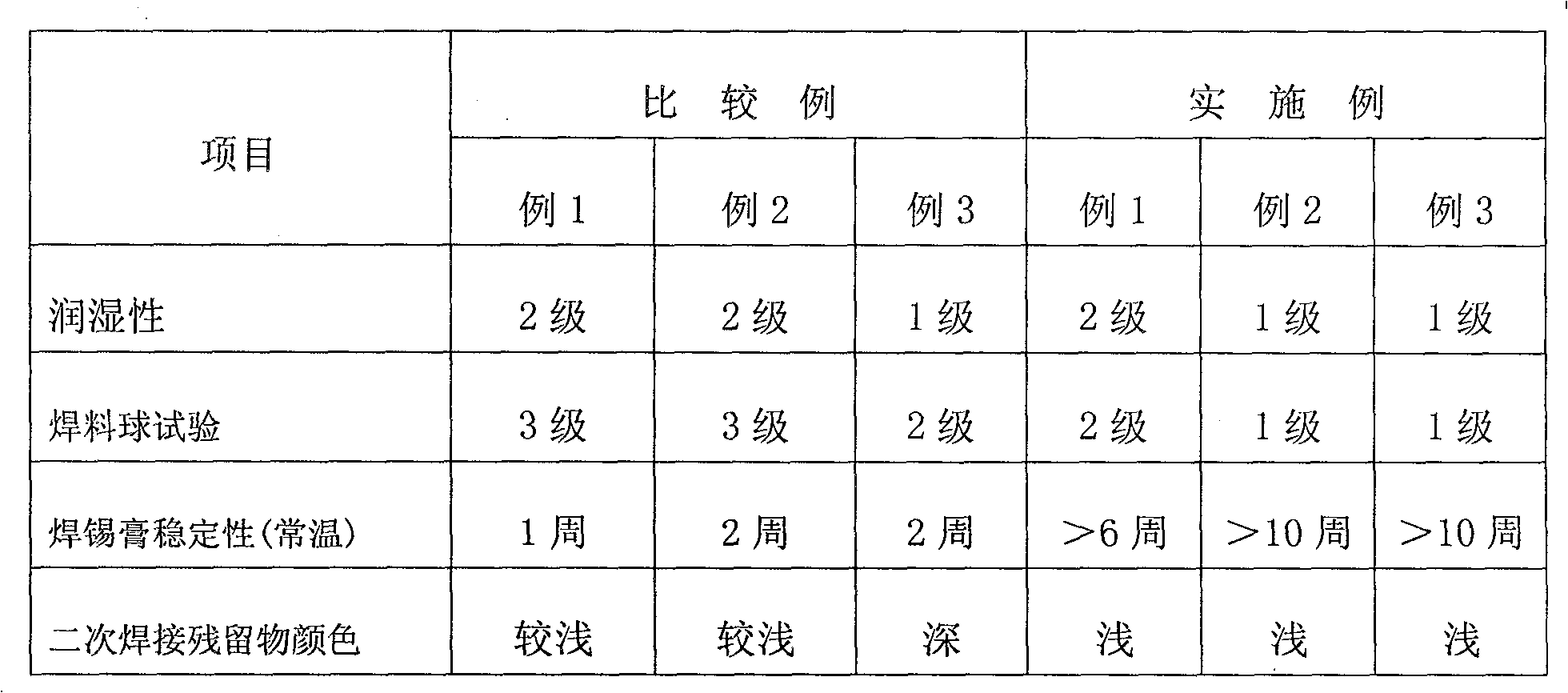

[0017] After making the products of the above comparative examples and examples, referring to the detection method of SJ / T11186-1998 "General Specification for Tin-Lead Paste Solder", it was tested for wettability, solder ball and observed the storage stability of solder paste , The color and storage stability of the secondary reflow soldering res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com