Radial settling tank with multiple layer settlement plate

A settling plate and settling tank technology, which is applied in the field of agricultural engineering, can solve the problems of easy sedimentation of particles and the inability to use large-scale settling tanks, and achieve the effects of increasing the settling area, improving volume utilization, and reducing operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

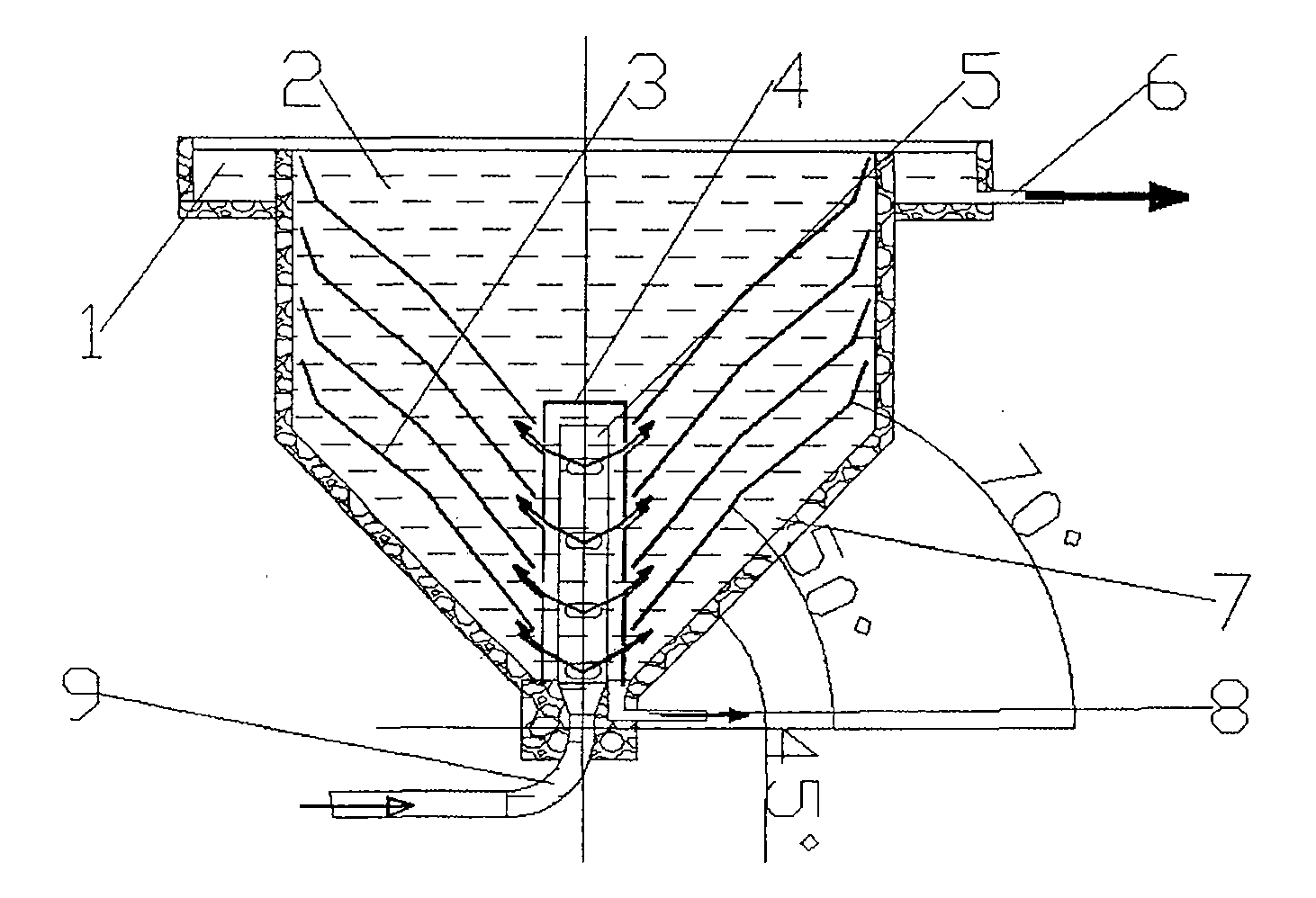

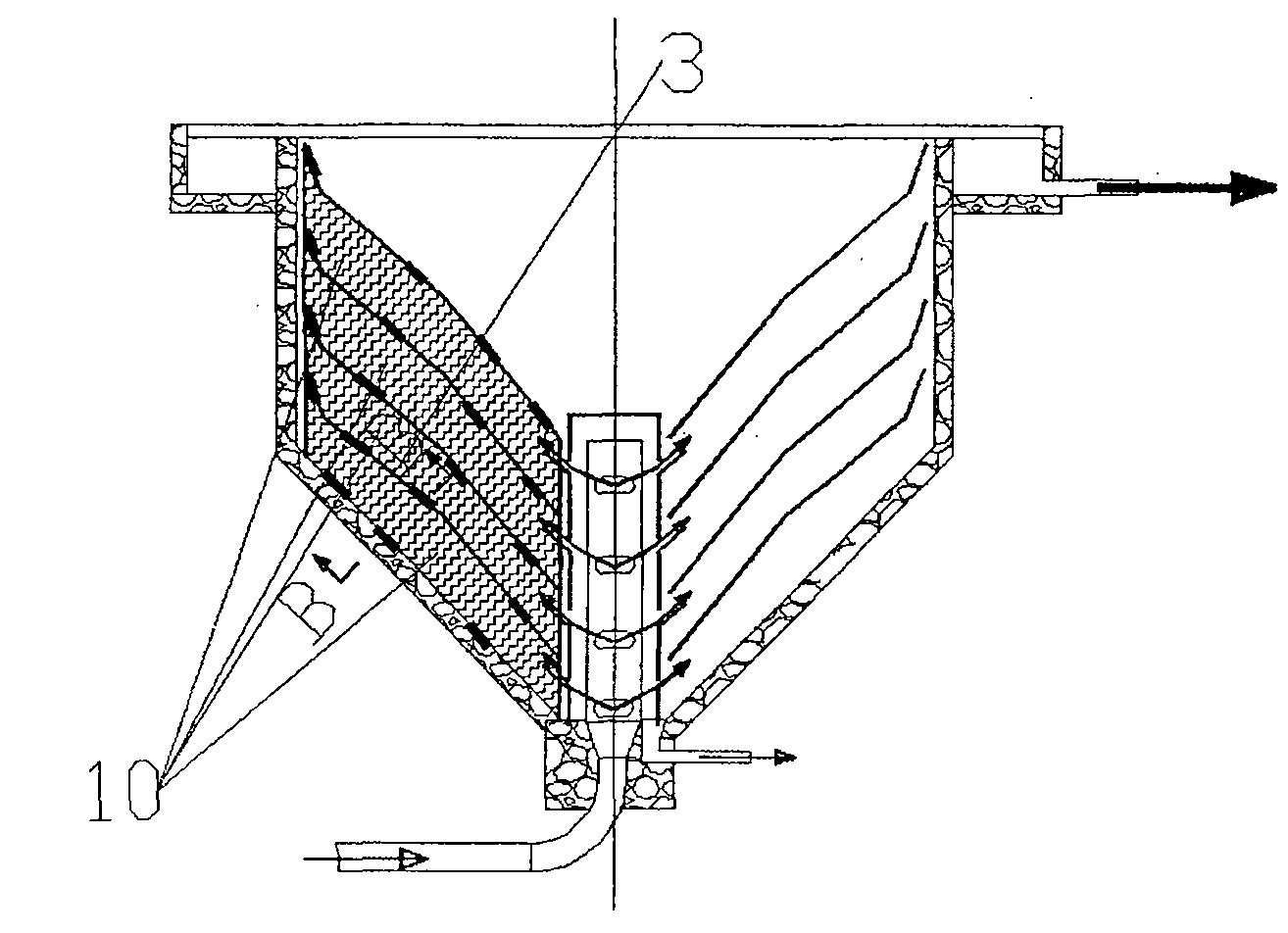

[0027] in figure 1 Middle: 1 is the sump, 2 is the main body of the sedimentation tank, 3 is the settling plate, 4 is the water distribution tube, 5 is the water inlet pipe, 6 is the clear water pipe, 7 is the sludge hopper, 8 is the sludge pipe, 9 is the sewage inlet pipe .

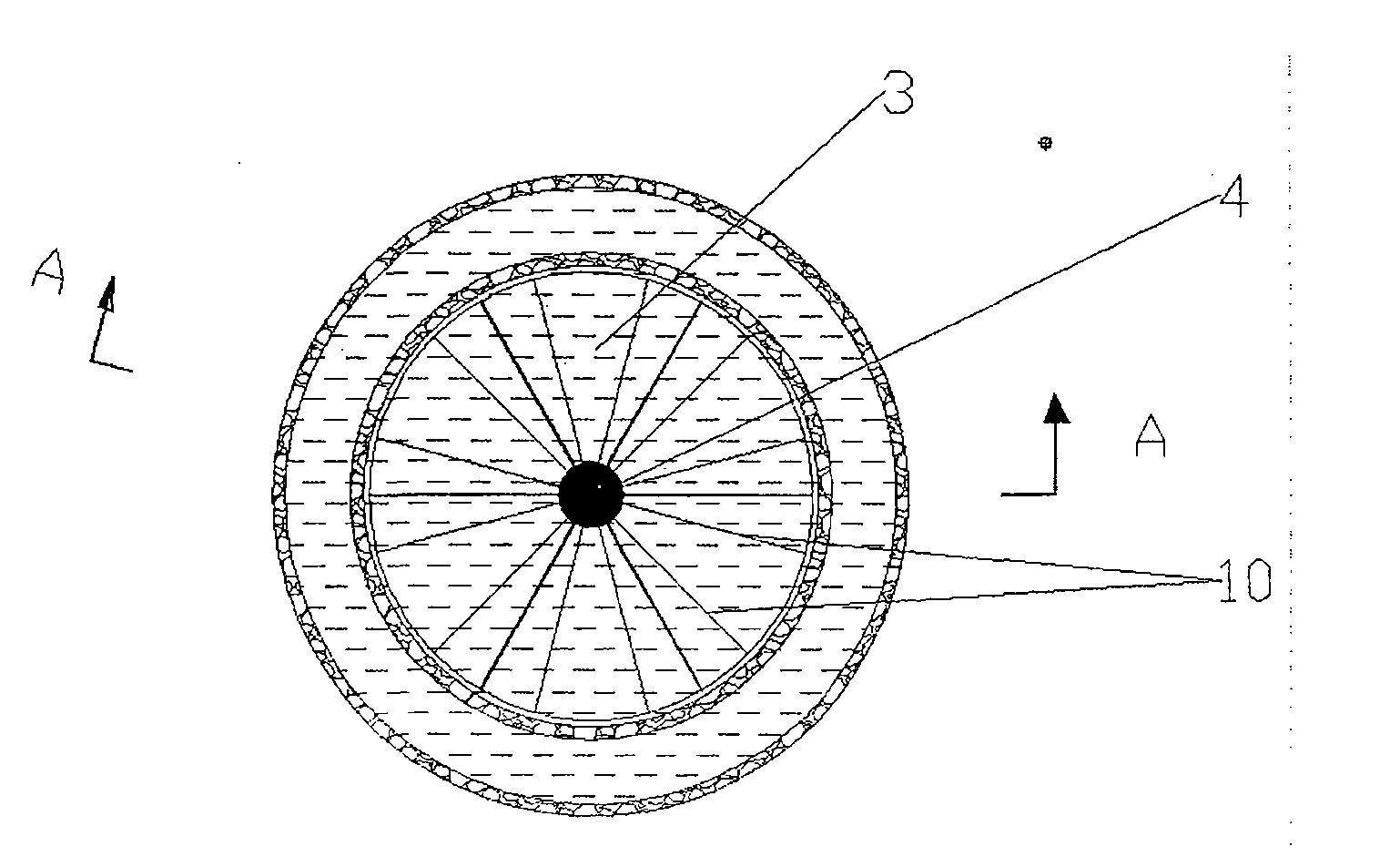

[0028] in figure 2 Middle: 10 is the radial baffle.

[0029] in Figure 4 Middle: 11 is the connecting bolt.

[0030] in Figure 5 Middle: 12 is the water deflector; 13 is the mud trap; 14 is the water outlet.

[0031] in Figure 6 Middle: 16 is a mud scraper.

[0032] The main body 2 of the sedimentation tank is a regular polygon or a circle; the sedimentation plate 3 is a truncated truncated (or truncated trellis) surface formed by a group of small plates distributed along the circumference and forming an angle of 45 to 75 degrees with the horizontal plane, and the truncated truncated truncated (or truncated trellis) surface The inside is low and the outside is high; there are grooves on the settlement su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com